It is used for tightly holding round or hexagonal work and is renowned for its automatic, fast centring ability. After you have clarified that a chuck lathe is universal, you must ensure all the options make it the right device. In this article, we will explore the question: Are lathe chucks universal?

Are Lathe Chucks Universal?

Not all are lathe chucks universal because different types of chucks are available in the market that’s why Some chucks are individually adjusted, whereas those chucks as universal have three of four jaws interconnected via a scroll gear, which can be set to a broader type setting or narrower setting using a single tool.

What is a Lathe Chuck?

Lathe chucks are a main part of a lathe machine tool which is used to hold and rotate a piece of work while performing a function of lathe operation.

Regular and asymmetrically shaped products can be held by the chuck, especially, those that lack radial symmetry. As well as lathe, chucks lathe machines are also commonly used in milling machines.

So the chuck lathe is attached to the spindle lathe by bolts and bobs, with the backplate lathe screwed onto the spindle.

Lathe Chuck Types

There are many different types of lathe chuck types we will discuss in this article.

-

Magnetic сhuck

Machinists use a magnetic chuck lathe for grinding objects and turning wood and metal. They especially use it to hold thin workpieces or metal and wood objects that an ordinary chuck cannot secure.

In addition, operators use a magnetic chuck lathe when there is a high need to keep the workpiece unmarked by jaw pressure, as it helps reduce this risk.

When the chuck lathe is in the ON position, the flux tool passes through the workpiece, gripping it. When the chuck lathe is In the OFF position, the magnets chuck are set aside, so bringing them in contact with high keepers

-

Four-Jaw independent chuck

Manufacturers construct the four-jaw independent chuck lathe from hardened steel, incorporating three inner gripping surfaces and one outer gripping surface. Since users can reverse all four jaws, they often use the outer surface to hold larger workpieces. Operators use four separate lathe screws to control the scroll disc, allowing each jaw to open and close independently.

The Four-Jaw independent chuck works without the use of a scroll. Four Jaw chuck move within their own jaw-ways and move very independently to fit irregular workpieces.

-

Combination сhuck

Users commonly choose this type of chuck because it can function as both a self-centering and an independent chuck lathe. It allows the jaws to move either simultaneously or independently, enabling it to perform both functions.

This Combination chucks lathe allows the user operator to set the jaws lathe to a workpiece, also insert a chuck key into the chuck lathe body, and turn a scroll joint with each other to all four jaw screws to move the jaws to and from a workpiece at accurate intervals.

Similar to a jaw-independent chuck lathe, the setting of the parts process of a combination chuck lathe is more time-wasting than that of a self-centring chuck lathe.

-

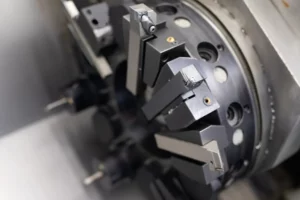

Three-jaw or universal chuck

Machinists most commonly use the universal chuck lathe in lathe machines.

Machinists use it to tightly hold round or hexagonal workpieces, and they value it for its automatic, fast centering ability. It can however sometimes wear quickly, due to only having three centring jaws chuck, useless gripping capacity and centring precision over time.

Manufacturers build the three jaw chuck using high-quality, hardened steel, and they position the jaws at 120-degree angles to each other.

During the working, the three jaw teeth mesh with scrawl spiral teeth. This creates a moment of all three jaws either towards or far away from the lathe chuck centre, which is dependent upon the direction of rotation of the bevel.

-

Collet chuck

Machinists use this type of lathe chuck for work that requires high precision centering and quick setup. They often use a collet chuck, which forms a collar around the object and securely fastens it to the project when screwed tightly. Normal usage of this chuck lathe is for holding bar stock in production work where precision is the main key, as well as in the industry world for the cutting of tools and workpieces at high pressures and control speeds.

Nut shelves made from a thin cylindrical bushing called a collet chuck match it with the spindle. The inside bore of the collet chuck can be cylindrical, hexagonal or square, depending on the work which is going through it.

-

Drill chuck or Jacob chuck

The Jacob chuck uses a centering jaw mechanism operated by rotating a key. Typically, machinists hold it in a tailstock or headstock spindle tool. Moreover, it secures straight-shank drills during drilling, reaming, or tapping operations. The Jacob chuck specializes in self-centering and excels at securely holding drill bits or similar tools during precise machining tasks.

Conclusion

Machinists set up a lathe chuck with one key that turns a scroll and classify it as a universal chuck. After you have clarified that a chuck lathe is universal, you must ensure all the options that make it the right device. Purchasing a lathe woodchuck will change how you use your lathe chuck and help you produce turned pieces of wood or metal of which you feel good.

FAQ’s

How can I choose a chuck for my lathe?

It is very important to check the workpiece requirements. Then check the machine requirements to be certain they are compatible with this chuck that you are using. So Choose a chuck jaw lathe which requires less time and effort as well as calculations to find the right piece for maximum accuracy.

Which one best lathe chuck type is recommendscroll gear,scroll gear,ed for woodturning?

The four jaw chuck actively holds and secures wood during the woodturning process. Although it is possible to turn a wood bowl without a chuck we sometimes use it for turning, the four-jaw woodturning chuck makes this work easier.

What to Look For in a Chuck?

- Size of the chuck.

- Workpiece dimensions.

- Workpiece material.

- Production volume (hard or soft jaws)

- Maintenance expectations.

- The manufacturing process (what rpm will the chuck run at given the size and weight of jaws and part)