A Big Bore Lathe is an essential tool for industries that require precise machining of large and heavy components. These machines are designed to handle wide-diameter workpieces while providing exceptional stability, accuracy, and operational efficiency that standard lathes cannot match. Industries such as aerospace, automotive, energy, and oil and gas rely on these lathes to maintain consistent, high-quality output across a variety of complex applications.

This comprehensive guide will explain the key characteristics, advantages, and industrial uses of these machines, along with tips for selecting the right lathe for specific needs. We will also cover expert maintenance practices and address frequently asked questions, giving professionals and enthusiasts a complete understanding of their critical role in modern manufacturing.

What Is a Big Bore Lathe?

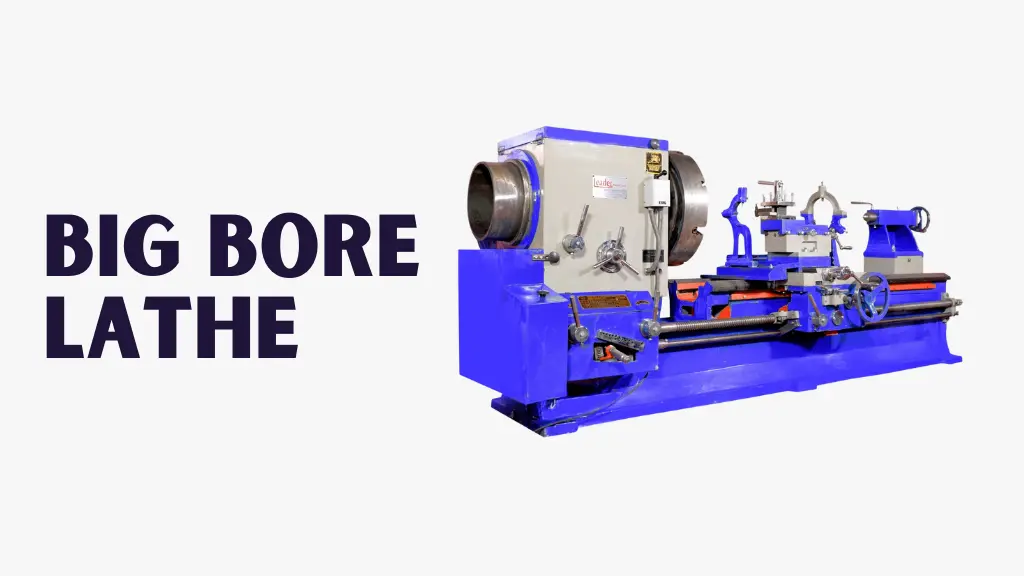

A big bore lathe is a specialized machine designed for turning operations on workpieces with large diameters. Unlike standard lathes, these machines feature reinforced spindles, heavy-duty beds, and powerful motors capable of handling substantial loads. Their primary advantage lies in machining oversized components while maintaining high precision, a level of accuracy conventional lathes often cannot achieve.

Specifications vary based on manufacturer and intended application. Swing-over-bed measurements typically start at 24 inches and can extend much higher, while spindle bore diameters usually exceed 12 inches. Industrial models often feature motors of 10 HP or more, allowing them to handle heavy workpieces efficiently. Maximum turning lengths can reach 10 feet or more, making these machines ideal for producing shafts, rollers, turbine casings, and other large-scale components.

These machines are favored by manufacturers for their combination of precision and strength, which is essential in heavy-duty industrial operations. For example, a steel producer creating large rollers for conveyor systems benefits from the lathe’s ability to maintain uniform diameters with minimal vibration. This level of accuracy directly influences the quality, durability, and reliability of the finished product, demonstrating their critical role in modern manufacturing.

Features of Heavy-Duty Lathes

One of the defining capabilities of a big bore lathe is its large swing capacity, which determines the maximum diameter of a workpiece that can be machined without interference. This feature is critical for industries handling oversized components, such as aerospace and heavy machinery manufacturing. By allowing operators to work on larger parts on a single machine, it reduces the need for multiple setups or extra equipment. Experienced machinists note that swing capacity directly impacts both productivity and precision of finished components.

The heavy-duty spindle is another essential feature, designed to withstand high torque while rotating large, dense workpieces. Reinforced spindles with precision bearings minimize deflection, ensuring consistent accuracy even under heavy loads. Experts in precision engineering highlight that spindle stability is crucial for maintaining tight tolerances in sectors like aerospace, automotive, and energy production. Reliable spindle design enhances product quality and extends the machine’s service life.

Stability, versatility, and modern automation further define big bore machine. The bed and frame are built from robust materials to absorb vibrations and support heavy components, ensuring high-quality results while minimizing wear. These machines accommodate multiple tooling configurations, including facing, threading, and boring, allowing complex operations on a single lathe. CNC-compatible models offer automated operation, repeatability, and precision, reducing human error in high-volume production environments.

Industrial Applications

Industries across aerospace, automotive, and energy sectors rely on specialized lathes capable of machining large and heavy components with exceptional precision. In aerospace manufacturing, these machines are critical for producing turbine shafts, landing gear parts, and large engine components. Tight tolerances are mandatory in this sector, and the accuracy of such lathes ensures safety and optimal performance, even when working with oversized workpieces.

In the automotive and transportation industries, these lathes are used to create crankshafts, large rollers, and other heavy-duty drive components. Maintaining consistent diameters and smooth surface finishes is essential for long-term durability and efficient operation. The oil and gas sector also depends on these machines for drilling equipment, pipe fittings, and industrial valves, while the railway industry uses them for axles, wheels, and couplers. Precision machining in these applications is critical to meet strict industry standards and prevent operational failures.

The energy sector benefits from these machines when producing wind turbine shafts, generator rotors, and other large-scale components. High-quality equipment maintains tight tolerances on massive parts, ensuring reliable and efficient performance. For instance, a turbine manufacturer recently used a CNC lathe to machine rotor shafts over 12 feet in length, achieving tolerances as precise as ±0.002 inches. This example highlights the crucial role of such machines in delivering precision, reliability, and safety in high-stakes industrial applications.

Advantages

The primary advantage of these lathes is their ability to handle workpieces much bigger than what standard machines can accommodate. This capability allows manufacturers to complete projects that would otherwise require multiple setups or additional equipment, saving time and reducing the likelihood of errors.

Precision is another significant benefit. The robust construction of these machines minimizes vibrations, ensuring accurate machining even under heavy loads. Such stability is critical in applications where maintaining tight tolerances is mandatory for quality and safety.

Versatility is also a key strength. These lathes support a variety of tooling operations, enabling operators to perform multiple tasks without moving workpieces between machines. CNC-enabled models enhance this flexibility further by allowing automated, repeatable operations suitable for mass production.

Additionally, these machines improve overall production efficiency. Automated and CNC-controlled operations reduce manual intervention, allowing operators to complete more work in less time without compromising quality. Their durability and long lifespan make them a cost-effective investment, while secure designs reduce the risk of accidents during operation.

Choosing the Right Big Bore Machine

Selecting the appropriate big bore lathe involves several critical considerations. Swing over bed measurements must accommodate the largest intended workpiece to ensure efficient operation. The spindle bore size is equally important, as it determines the maximum internal diameter the lathe can handle.

Motor power and torque are other essential factors. A machine must have sufficient power to handle heavy workpieces without compromising precision or speed. Bed length should also be considered to support the full workpiece and allow for effective machining operations.

Accuracy and repeatability are critical for applications requiring tight tolerances. Manufacturers provide tolerance ratings, which should be reviewed carefully before purchasing a lathe. Tooling options such as facing, threading, and boring capabilities should align with the types of operations required in your production environment.

Finally, deciding between CNC and manual control depends on production needs. CNC models offer automation, consistency, and high repeatability, making them ideal for large-scale operations, while manual models are better suited for smaller projects or workshops with simpler machining tasks. Consulting manufacturer specifications, reviewing case studies, and evaluating user experiences can help ensure the chosen machine meets operational requirements.

Maintenance and Safety Tips

Proper maintenance is essential to maximize the lifespan and performance of a bore lathe. Lubricating bearings and spindles regularly prevents wear and reduces friction, while checking alignment and levelness ensures consistent accuracy. Inspections of belts, gears, and coolant systems are necessary to maintain smooth operation, and worn or damaged parts should be replaced promptly to avoid operational failures.

Safety is equally important. Operators should wear appropriate protective gear, including gloves and goggles, and keep hands and loose clothing away from moving parts. Proper clamping methods must be used for heavy or large workpieces to prevent accidents. Following manufacturer-recommended safety procedures and conducting regular safety audits help maintain a secure working environment while ensuring consistent, high-quality results.

Conclusion

A big bore lathe is an indispensable tool for industries that require high-precision machining of large and heavy components. These machines combine stability, accuracy, and versatility, making them ideal for aerospace, automotive, energy, oil and gas, and railway applications. Proper selection, regular maintenance, and adherence to safety guidelines ensure long-term reliability and consistent production quality. Investing in a high-quality machine allows manufacturers to achieve superior efficiency, maintain strict tolerances, and produce large-scale components with confidence.

FAQs

What is the maximum diameter these lathes can handle?

These lathes can accommodate workpiece diameters ranging from 12 inches to over 60 inches, depending on the model. Custom solutions are also available to meet specialized industrial requirements.

Can these lathes machine multiple types of materials?

Yes, these machines can handle metals such as steel, aluminum, titanium, and high-strength alloys, as well as plastics and composite materials, making them versatile for various industrial applications.

What industries rely heavily on these machines?

Aerospace, automotive, energy, oil and gas, and railway industries rely heavily on these machines for precision machining of large and heavy components.

Are CNC bore lathes better than manual models?

CNC models provide higher precision, automation, and repeatability. They are ideal for mass production, while manual models remain cost-effective for smaller workshops or less complex tasks.

How often should maintenance be performed?

Routine maintenance should be carried out daily, with more comprehensive checks weekly or monthly depending on usage. Regular inspections of bearings, spindle alignment, and tool condition are essential for maintaining performance.