Broaching on a lathe is a highly specialized machining process that allows manufacturers and machinists to create precise internal and external profiles on metal components. Unlike conventional turning or milling, it provides a unique combination of precision, efficiency, and repeatability. While it is less commonly used than other machining techniques, it has distinct advantages for certain low- to medium-volume applications. Understanding the principles of broaching is essential for engineers and machinists seeking to achieve high-quality results in their work.

This guide provides an in-depth look at broaching, covering everything from types and tools to applications, techniques, and best practices. The content aims to provide readers with practical insights and expert advice that can be applied in real-world machining operations.

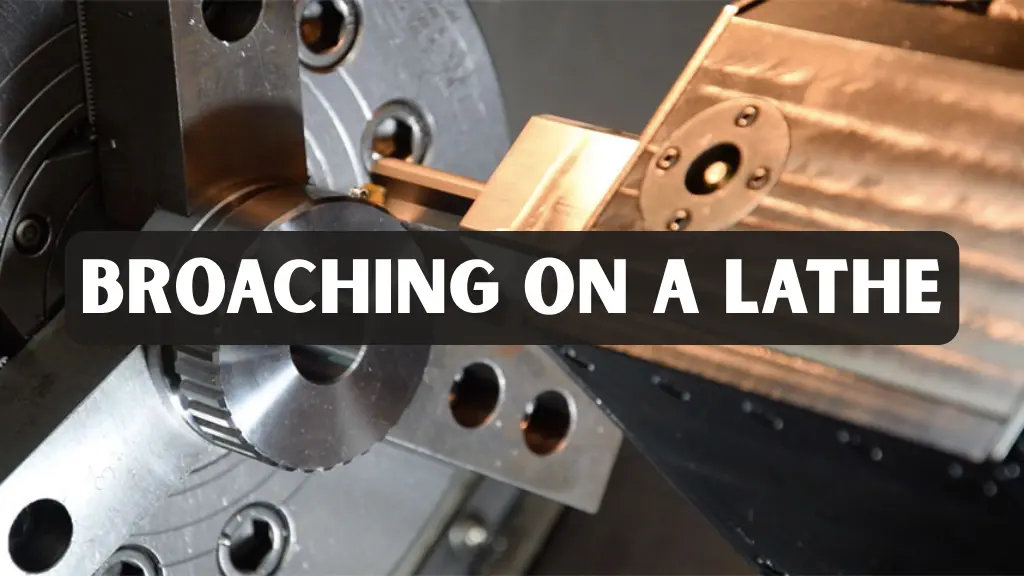

What is Broaching on a Lathe

Broaching on a lathe involves using a toothed cutting tool called a broach to remove material from a workpiece. The tool is either pushed or pulled through the material, gradually shaping it to the desired form. This method allows for high-precision results with smooth finishes. Broaching is especially useful when creating keyways, splines, or complex profiles that require tight tolerances.

The process begins by mounting the workpiece securely in the lathe chuck. The broach is then aligned carefully and fed across the workpiece. Proper lubrication and controlled motion are essential to prevent tool wear and achieve accurate cuts. One of the key advantages of lathe broaching is that it can produce uniform profiles in a single pass, reducing the need for multiple operations. This makes it particularly valuable in prototype development or in situations where specialized components are required in low quantities.

Broaching is often preferred for specialized or prototype components because it allows machinists to achieve precise results without requiring expensive CNC broaching machines. It combines manual skill with mechanical accuracy, making it a versatile option in precision machining. Skilled operators can also make minor adjustments during the process, ensuring that each part meets stringent quality standards.

History and Evolution of Broaching

Broaching has been an essential machining technique since the late 19th century. Initially, it was used primarily for cutting keyways in gears and other mechanical components. The early machines were manually operated, and tool designs were relatively simple. As industrial demands increased, innovations in tooling, material science, and machine design expanded the capabilities of broaching.

The integration of lathe broaching allowed machinists to perform both internal and external cuts with minimal setup time. This development enabled smaller workshops to achieve high-quality results without investing in large-scale CNC machines. Over the years, the use of carbide-tipped broaches, high-speed steel, and advanced lubricants has significantly improved the efficiency and precision of the process.

Today, broaching is widely used in various industries, including automotive, aerospace, tooling, and prototype manufacturing. The evolution of broaching demonstrates its adaptability and the continued relevance of lathe-based techniques in modern machining environments. Understanding the history of broaching helps machinists appreciate the technique’s versatility and its value in contemporary manufacturing operations.

Types of Broaching

Broaching on a lathe can be divided into internal and external operations, each serving distinct machining needs. Internal broaching focuses on removing material from within a hole, making it ideal for keyways, splines, and circular profiles. The process typically starts with pre-drilling or pre-boring the workpiece to create an entry point for the broach. This preparatory step ensures precision and reduces the risk of tool damage during cutting.

Once the hole is prepared, the internal broach is carefully inserted and gradually fed through the workpiece. Maintaining precise alignment is critical to prevent tool binding and achieve an even, high-quality cut. Consistent feed rates combined with proper lubrication help preserve the broach teeth and maintain surface finish standards. Skilled operators rely on experience to judge the optimal feed and cutting pressure for different materials.

External broaching, in contrast, is used to shape the outside of a component, producing flat surfaces, grooves, or other profiles. Since external broaches do not require alignment within a hole, they are generally easier to handle on a lathe. The workpiece is securely mounted, and the broach is fed along the surface in a controlled motion. This ensures uniform material removal and a smooth, precise finish, especially on cylindrical or rounded parts.

Both internal and external broaching techniques offer unique advantages for precision machining. Internal broaching allows the creation of complex internal shapes that would be difficult with other methods. External broaching, meanwhile, provides accurate external profiles with minimal setup time. Mastering both approaches gives machinists the expertise to handle a wide variety of projects, ensuring consistent quality and reliable results across different materials and applications.

Lathe Broaching Compared to CNC Broaching

Although CNC broaching machines dominate high-volume production environments, lathe broaching continues to have unique advantages for specialized operations. CNC machines offer high precision, repeatability, and automation, making them ideal for mass production. Skilled operators, however, can achieve excellent tolerances using a lathe, particularly for prototypes or small batches.

Lathe broaching is often manual or semi-automatic, allowing machinists to make real-time adjustments during the cutting process. Setup time is generally shorter for lathe broaching, which is advantageous when producing low-volume or custom components. The cost of lathe broaching is also lower compared to CNC broaching, as it does not require expensive machinery or complex programming. However, for large-scale production runs, CNC broaching provides better efficiency, higher repeatability, and lower per-part costs.

Choosing between lathe and CNC broaching depends on production requirements, available resources, and the desired level of precision. For projects requiring a small number of high-precision components, lathe broaching can provide excellent results without significant investment in advanced machinery.

Tools and Equipment Needed for Lathe Broaching

Successful broaching operation requires specific tools and equipment. The primary tool is the broach itself, a toothed cutting instrument designed for the specific profile being machined. The lathe must be capable of controlled linear feed and stable workholding, as excessive vibration can lead to inaccuracies or tool damage.

Securing the workpiece is crucial. Chucks, collets, or specialized fixtures are used to hold components firmly in place during the cutting process. Lubricants play an essential role in reducing friction and heat generation, which helps extend tool life and improves surface finish. Additionally, precise measuring instruments such as micrometers, calipers, and gauges are necessary to verify that dimensions meet specified tolerances.

The choice of broach material depends on the hardness of the workpiece. High-speed steel (HSS) is suitable for most metals, while carbide-tipped broaches are preferred for harder materials such as stainless steel or hardened alloys. Proper tool selection ensures both accuracy and durability throughout the machining process.

Step by Step Guide to Broaching

Performing broaching requires attention to detail, patience, and adherence to safety standards. The first step is to prepare the workspace and select the appropriate broach and lubricants. Safety equipment, including gloves and protective eyewear, should be used to prevent injury during operation.

Next, the workpiece is mounted securely in the lathe chuck. Ensuring that the component is stable is critical to avoid vibration or slippage, which can compromise accuracy. The broach is then aligned carefully with the desired cutting path. Proper alignment prevents tool binding and ensures uniform material removal.

Once alignment is complete, the broach is gradually fed along the workpiece. Applying consistent pressure and maintaining a controlled feed rate is essential to achieving a smooth surface finish. Operators must monitor the process closely, watching for vibration, chatter, or excessive heat. Adjustments to feed or lubrication may be necessary to maintain optimal cutting conditions.

After the broaching operation is complete, the workpiece is inspected for dimensional accuracy. Cleaning and deburring may be required to remove any residual material. Following these steps ensures that the final component meets specifications and exhibits high-quality surface finishes.

Advantages of Lathe-Based Broaching

Broaching on a lathe offers several advantages over conventional machining methods. It can produce highly precise surfaces with tight tolerances in a single pass, reducing the need for secondary finishing operations. The process is efficient for low- to medium-volume production, making it ideal for prototypes or specialized components. Additionally, lathe broaching allows the creation of complex internal and external profiles that are difficult to achieve with standard milling or turning operations.

For small workshops or manufacturers producing custom components, lathe broaching is a cost-effective alternative to CNC machines. The ability to adjust cutting pressure and feed in real-time provides greater control over the machining process and allows operators to handle unique or irregular workpieces with confidence.

Limitations and Challenges

Despite its advantages, lathe broaching has limitations. The technique requires skilled operators to maintain precision and prevent tool damage. It is less suitable for high-volume production compared to CNC broaching, where automation ensures repeatability and efficiency. Tool wear can affect both dimensional accuracy and surface finish, necessitating careful monitoring and maintenance. Alignment and setup are critical, and improper handling may lead to inaccuracies or breakage. Understanding these challenges is essential for maximizing the effectiveness of lathe broaching.

Applications of Lathe Broaching

Lathe broaching is widely used across multiple industries. In the automotive sector, it is employed for producing keyways, gear splines, and bushings. Aerospace manufacturers rely on lathe broaching for precision fittings and control components. Tooling and die-making applications include the production of custom dies, molds, and specialized tools. Prototype manufacturing benefits from lathe broaching because it allows low-volume production of complex profiles with minimal setup. Additionally, repair shops often use lathe broaching to produce custom or obsolete components that require precise machining.

A practical example of its application is a small aerospace workshop that reduced keyway machining time by 40 percent by switching from conventional milling to lathe broaching for low-volume prototype production. This change not only improved surface finish and dimensional accuracy but also streamlined the workflow, demonstrating the efficiency of lathe broaching in specialized applications.

Best Practices

Achieving optimal results in lathe broaching requires adherence to best practices. Operators should use the correct broach material and profile for the workpiece to avoid premature wear or inaccuracies. Consistent feed rates are essential to maintain uniform cuts, while proper lubrication reduces friction and heat. Inspecting broach teeth regularly ensures that worn tools do not compromise quality.

Maintaining a clean workspace prevents contamination that could damage the broach or the workpiece. For deep or complex profiles, pre-machining holes or surfaces can reduce stress on the tool and improve cutting efficiency. Following these guidelines enhances tool life, improves precision, and promotes safety during broaching operations.

Conclusion

Broaching on a lathe remains a versatile and effective machining technique for producing precise internal and external profiles. Although it is less common than CNC broaching, it is invaluable for low- to medium-volume production, prototyping, and specialized components. By understanding the process, selecting the right tools, and adhering to best practices, machinists can achieve high-quality results efficiently and safely.

FAQs

Can any lathe be used for broaching

Not all lathes are suitable. The machine must allow controlled linear feed and stable workholding. Precision and rigidity are essential to prevent tool damage and achieve accurate cuts.

How do I choose the right broach

Select the broach based on workpiece material, profile complexity, and depth of cut. High-speed steel is standard for most metals, while carbide-tipped broaches are recommended for harder materials.

Is broaching faster than milling

Broaching can be faster and more accurate than milling for single-pass precision cuts, particularly for internal keyways or splines.

How do I maintain broach tools

Regular cleaning, inspection for tooth wear, and proper storage are essential. Using the correct lubrication also prolongs tool life.

Can broaching be used on curved surfaces

Broaching is generally linear. For curved or irregular profiles, CNC or specialized milling machines are more appropriate.