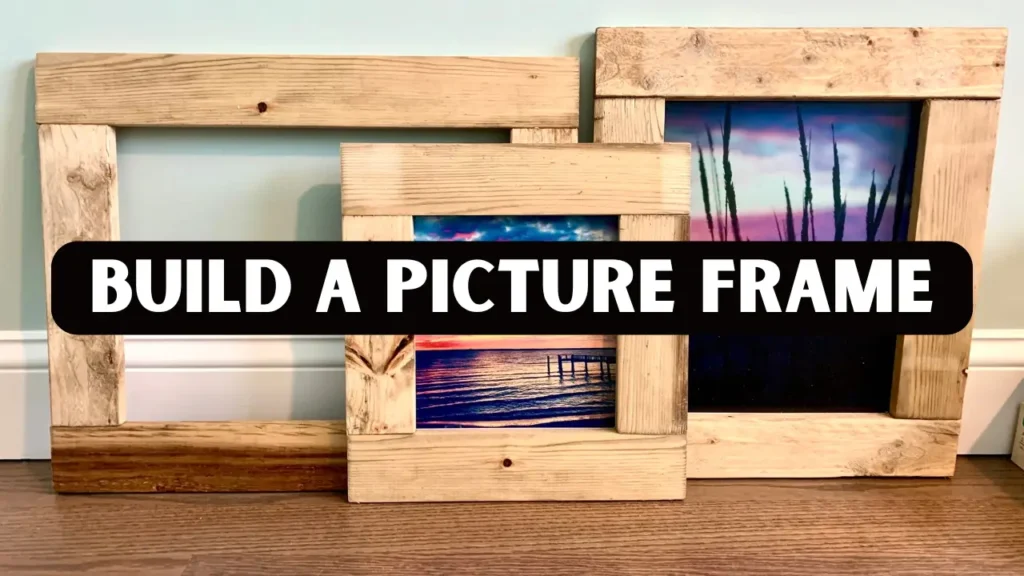

Building a picture frame is a fulfilling woodworking project that combines creativity, precision, and practical skill. For woodworking enthusiasts, it provides an opportunity to practice essential techniques while producing a frame that perfectly fits a piece of artwork or a photograph. Creating your own frame allows complete control over the size, wood type, edge design, and finish, resulting in a unique piece of décor that reflects personal style and craftsmanship.

Whether you are a beginner eager to develop basic skills or an experienced woodworker looking to experiment with lathe-turned edges, this guide will teach you how to build a picture frame that is both functional and visually appealing. Throughout this process, you will gain hands-on experience in measuring accurately, cutting precisely, shaping with a lathe, and finishing wood surfaces to a professional standard.

Why Build a Picture Frame Yourself

Building a frame yourself allows for full personalization. When you decide to build a picture frame, you can select the type of wood, determine the width and depth, and design the edge profile according to your taste. Using a lathe, it is possible to create rounded or fluted edges that transform a simple frame into a piece of art. Unlike store-bought frames, handmade frames provide the freedom to experiment with different shapes, finishes, and designs, adding a creative and unique touch to any room.

The process of creating a frame also helps develop essential woodworking skills. Learning how to measure accurately, mark cutting lines, and maintain consistent angles is important for any woodworking project. Using a lathe to shape edges enhances precision control, while assembling and gluing the pieces strengthens your understanding of joint durability and overall construction. These skills are easily transferable to furniture making, cabinetry, and other decorative woodworking projects.

Cost-effectiveness is another advantage of building your own frame. High-quality or custom frames from stores can be expensive, especially for larger or intricately designed pieces. By making the frame yourself, you can use reclaimed wood or small hardwood scraps, significantly reducing material costs while still achieving professional-quality results. A well-crafted frame also demonstrates skill and attention to detail, as precision cutting, joining, and finishing produce a premium-looking, entirely handmade piece.

Materials and Tools Needed

For a successful frame project, start with quality materials. Hardwood planks such as oak, maple, or cherry are ideal for durability and smooth turning on a lathe, while softwoods like pine are easier for beginners. Additional materials include wood glue for strong joints, clamps to hold pieces in place during assembly, sandpaper in various grits ranging from coarse to fine for smooth finishing, and a wood stain, paint, or natural finish to enhance the appearance. To protect the artwork, a glass or acrylic pane and a backing board made of cardboard, foam, or MDF are required.

Equally important are the tools. A miter saw is essential for cutting accurate 45-degree angles at corners. A lathe allows for creating rounded or fluted edges, giving the frame a polished and professional look. Chisels and mallets help with shaping, while measuring tapes and square rulers ensure precise dimensions. Optional tools include routers for decorative profiles and a drill with screws or finishing nails to reinforce joints. Safety equipment, including gloves, goggles, and a dust mask, is necessary when cutting, turning, or sanding wood. Selecting the right combination of materials and tools ensures a smooth process and a high-quality finished frame.

Step by Step Frame Making Guide

Step 1: Planning and Measuring

Accurate planning is the foundation of any woodworking project. Begin by determining the size of the photograph or artwork that will be displayed. From there, add the desired width of the frame to calculate the overall dimensions. Using a square ruler ensures that all corners form perfect right angles. For frames that incorporate lathe-turned edges, it is often easier to perform lathe work on longer boards before cutting them to the exact lengths needed for the frame. This approach allows for smoother shaping and reduces the risk of uneven edges.

Step 2: Cutting the Wood

Cutting is a crucial step that affects the quality of the assembled frame. Use a miter saw to make precise 45-degree cuts at each corner, ensuring that all pieces will align perfectly. For frames with decorative lathe edges, shaping these edges before cutting ensures a consistent profile across all pieces. Measuring twice before cutting is essential to avoid mistakes and wasted material. Using a sled or guide on the miter saw can help achieve uniform cuts, especially when making multiple frames or intricate designs.

Step 3: Assembling the Frame

Once the pieces are cut, apply wood glue along the mitered edges and bring the corners together. Clamping the frame tightly allows the glue to set correctly while maintaining square angles. For added durability, small nails or screws can reinforce each joint. If the frame includes lathe-turned edges, either assemble the pieces first and refine the edges carefully on the lathe, or turn each piece individually before joining. This ensures that decorative features are maintained while creating a strong and stable frame.

Step 4: Sanding and Smoothing

Sanding is critical for a polished finish. Begin with coarse-grit sandpaper to remove any rough surfaces or imperfections from cutting and shaping. Gradually move to finer grits to achieve a smooth surface ready for finishing. Pay special attention to corners and lathe-turned edges, as these areas can be delicate and may require careful sanding. Sanding in the direction of the wood grain prevents scratches and maintains a professional appearance. Small sanding blocks or sponges are useful for intricate curves or fluted edges.

Step 5: Finishing the Frame

Applying the finish enhances both the durability and visual appeal of the frame. Stains should be tested on scrap wood before applying to the entire frame to ensure the desired color. Paint can be applied in thin, even layers, allowing each coat to dry thoroughly before adding another. Sealing with varnish or polyurethane protects the wood from moisture, scratches, and wear. For lathe-turned edges, use a soft brush to ensure that finish reaches all grooves and curves, preserving the decorative detail.

Step 6: Adding Glass and Backing

The final step is to prepare the frame for the artwork. Cut glass or acrylic to fit precisely, then insert the photograph or art piece. Secure the backing using clips, nails, or a custom support. Handling glass with care and wearing gloves is essential to prevent injuries. Once the glass and backing are in place, the frame is ready to display, offering a polished and professional presentation.

Advanced Lathe Techniques for Frames

Experienced woodworkers can elevate frame making by using a lathe to create intricate and decorative features. Adding fluted or grooved edges introduces elegance and sophistication, while rounded or beveled edges give the frame a smooth, professional appearance that enhances the overall design. These techniques allow even simple frames to stand out with a refined, custom look when you build a picture frame with attention to detail.

For more advanced projects, multiple turned pieces can be combined to produce multi-dimensional frames that are visually striking. This approach not only adds complexity and depth to the design but also showcases a higher level of craftsmanship, allowing woodworkers to create frames that are truly unique and demonstrate skill and creativity.

Common Mistakes to Avoid

Several mistakes can compromise the quality of a frame. Skipping sanding steps often leaves rough surfaces that are difficult to finish properly, while inaccurate measurements can result in misaligned corners and gaps at the joints. Frames with joints that are not reinforced with glue or fasteners may be weak and prone to separating over time, reducing both durability and visual appeal.

Another common error is applying stain or paint without testing it first. This can lead to uneven coloring or finishes that do not match your intended design. By being careful to sand thoroughly, measure accurately, reinforce joints, and test finishes, woodworkers can create frames that are strong, durable, and visually pleasing.

Tips for Beginners

For beginners, starting with softwood makes cutting and turning much easier, allowing for more forgiving practice as skills develop. Using scrap wood for initial projects provides an opportunity to experiment with techniques without wasting high-quality materials. Practicing lathe work on small dowels or pieces of scrap wood helps build control and confidence before moving on to full-size frames.

Additional tips can further improve results. Adding a mat enhances the presentation of the artwork, while double-checking all measurements before cutting prevents mistakes that could affect the overall fit and appearance. By following these guidelines, beginners can steadily develop their woodworking skills and create beautiful, well-crafted frames.

Real-World Example

Smith Solutions, a woodworking studio rated 4.9 stars by over 250 reviewers on Google, provides students with hands-on experience in building picture frames. The studio teaches the use of both hand tools and lathes, ensuring participants learn precise techniques. Students focus on accurate measuring and careful mitered corner assembly. Every step emphasizes attention to detail and quality craftsmanship.

In addition, participants explore decorative lathe techniques to create frames that are visually appealing and functional. The program demonstrates how structured instruction combined with practical practice produces professional results. Even beginners gain confidence in their woodworking skills. By the end of the course, students can craft frames that showcase both creativity and precision.

Conclusion

Learning to build a picture frame is a fulfilling project that allows woodworkers to combine creativity with precision. By carefully measuring, cutting, and assembling each piece, you can create a frame that not only fits your artwork perfectly but also reflects your personal style. Even beginners can achieve professional-looking results by following step-by-step techniques and paying attention to detail throughout the process.

Incorporating lathe work into your frame design adds a decorative touch, elevating the final product and showcasing advanced craftsmanship. With proper finishing, sanding, and attention to joinery, the completed frame becomes both durable and visually striking, making it a rewarding addition to any home or a thoughtful handcrafted gift.

Frequently Asked Questions

Can beginners build a picture frame with a lathe?

Yes. Beginners can start with simple edges and gradually progress to more complex lathe profiles as they gain confidence and skill.

What is the best wood for lathe-turned frames?

Hardwoods such as maple, oak, or cherry are recommended for durability and smooth turning. Softwoods like pine are easier for beginners but less resistant to dents or scratches.

How long does it take to make a frame?

A basic frame typically takes two to three hours. Frames with complex lathe-turned edges may require four to six hours, plus additional time for finishing.

Can frame size be customized?

Yes. Carefully measuring the artwork and adding the desired frame width ensures a perfect fit.

Should wood be finished before or after assembly?

Lathe-turned pieces often benefit from finishing before assembly, while simple frames can be finished after joining without compromising quality.