In modern machining, efficiency, precision, and safety are of paramount importance. One tool that has significantly improved workflow in metalworking and manufacturing shops is the CNC lathe bar puller, which automates the extraction of bar stock and minimizes manual labor. Traditionally, removing bar stock by hand required extra effort, increased downtime, and carried risks of spindle damage or operator injury. By automating this process, manufacturers can ensure consistent part quality while allowing operators to focus on other critical tasks.

Incorporating this tool into production processes helps create smoother operations, reduces human error, and enhances overall shop safety. This article provides a comprehensive overview of bar pullers, including their functionality, types, installation, benefits, maintenance requirements, and best practices, helping manufacturers understand and maximize the value of this essential machining accessory.

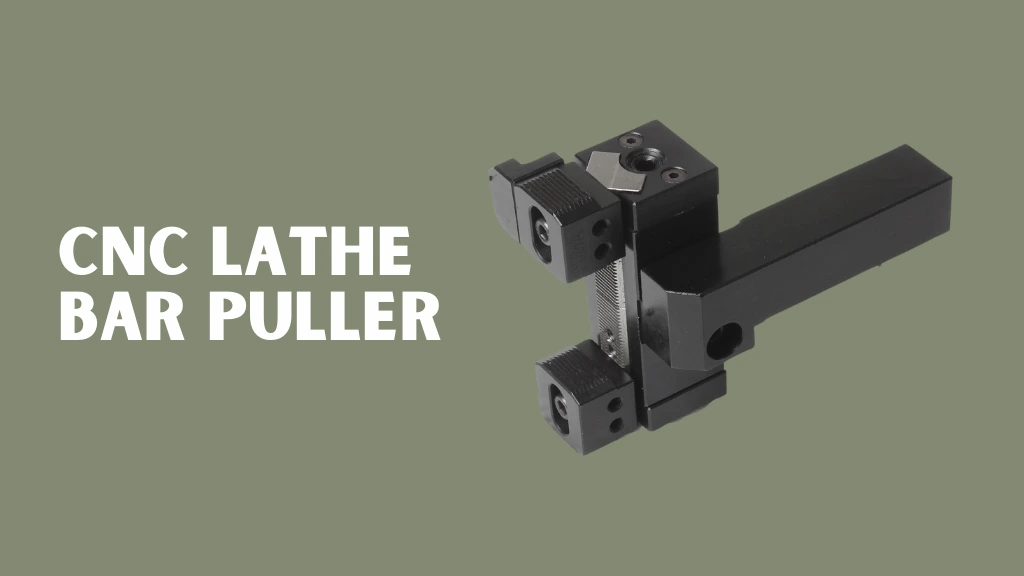

What is a CNC Lathe Bar Puller?

A CNC lathe bar puller is a device specifically designed to automatically extract bar stock from the lathe spindle. It operates in conjunction with the lathe’s CNC programming, which controls when and how the bar puller engages during the machining process. By removing the need for manual extraction, it reduces cycle times, prevents potential errors, and protects the spindle and tooling from accidental damage.

The bar puller grips the end of the bar stock, retracts it to the desired position, and releases it, all while the machine continues to operate. This process ensures uniformity in part length and repeatability across multiple cycles. Operators can monitor the production process or prepare the next batch of material while the automated bar puller handles extraction, increasing overall efficiency.

How Does a Bar Puller Work?

The operation of a CNC lathe bar puller is both precise and efficient. The mechanism first clamps securely onto the bar stock, holding it firmly during extraction. Once the CNC program activates the device, it retracts the bar to a predetermined position, ensuring the correct length is exposed for the next machining cycle or for removal. After extraction, the gripping mechanism releases the bar safely, preparing the machine for the next operation.

This automated process not only improves accuracy but also reduces the likelihood of operator error, which can lead to wasted material and machine downtime. By minimizing manual handling, the device enhances workplace safety and supports continuous production, even in high-volume operations. Many shops that have integrated bar pullers report significant increases in production speed while maintaining consistent part quality.

Types of Bar Pullers

There are several types of CNC lathe bar pullers, each designed for specific applications depending on the size of the bar stock, the material type, and production demands. Pneumatic bar pullers operate using compressed air and offer fast response times. They require minimal maintenance and are particularly suitable for lightweight bars. High-speed machining operations benefit greatly from their efficiency and speed.

Hydraulic bar pullers provide a more robust solution for heavier bar stock. They use hydraulic pressure to generate the necessary force for reliable extraction. These pullers are ideal for applications requiring substantial pulling power, such as large-diameter steel bars. They ensure consistent results even in demanding production conditions.

Mechanical bar pullers are the simplest and most cost-effective type. They rely on mechanical components like springs or cams to perform the pulling action. Their straightforward design makes them durable and less prone to failure. Mechanical pullers are ideal for smaller shops or operations with lighter production requirements.

Choosing the right type of bar puller is essential for smooth operation and minimal downtime. Matching the puller to production volume, material type, and machine specifications improves efficiency. Proper selection also extends the lifespan of both the lathe and the puller. This strategic choice can lead to measurable productivity gains in any machining environment.

Benefits of Using a Bar Puller

The integration of a lathe bar puller into machining operations offers numerous benefits. One of the primary advantages is increased efficiency. Automating the extraction of bar stock reduces cycle times and allows production lines to run more smoothly and continuously. Operators no longer spend time manually removing bars, freeing them to focus on other essential tasks.

Safety is another significant benefit. Manual handling of heavy or sharp bar stock poses risks of injury to operators. With a bar puller, the need for human intervention is minimized, reducing the likelihood of accidents and ensuring a safer workplace.

Consistency in part quality is also enhanced. Since the bar puller ensures that the same length of bar is exposed during each cycle, operators can achieve uniformity in part dimensions across multiple batches. This level of precision is particularly important in industries such as automotive and aerospace manufacturing, where even small variations can compromise product quality.

Moreover, proper use of a bar puller helps to prevent damage to the spindle and tools. By controlling the extraction process, the device avoids undue stress or impact on sensitive machine components, extending their lifespan and reducing repair costs. Overall, the use of bar pullers results in cost savings, improved productivity, and higher-quality output.

Installation and Setup Considerations

Proper installation and setup are essential for maximizing the benefits of a bar puller. Before installation, it is important to verify the compatibility of the puller with the lathe model and ensure that the spindle and bar stock dimensions match the puller’s specifications. Hydraulic and pneumatic connections should be checked for leaks and proper pressure to ensure reliable operation.

Programming the puller is another critical step. Integrate the commands for the bar puller into the CNC program to synchronize the extraction process with the machining cycle. It is also important to conduct test runs using sample bars to ensure that the mechanism operates smoothly and accurately.

Maintenance is key to long-term performance. Regularly lubricate the moving parts of the bar puller, inspect the gripping surfaces for wear or damage, and replace seals in hydraulic or pneumatic systems as needed. Keeping the mechanism free from debris and metal chips is also essential to prevent jamming and ensure smooth operation. Following these installation and maintenance practices will ensure reliable and consistent performance of the bar puller.

Best Practices for Maximizing Productivity

To get the most out of a bar puller, several best practices should be followed. Integrating the bar puller with a bar feeder allows for seamless and continuous operation, minimizing downtime and improving workflow efficiency. It is also important to train operators on proper usage, safety protocols, and troubleshooting techniques. Proper training ensures that the equipment is used correctly, reducing the risk of errors and potential damage to the machine or bar stock.

Monitoring production cycles and adjusting the puller speed based on the bar material and size can further optimize performance. Maintaining a detailed log of maintenance activities and production metrics helps identify potential issues before they escalate, ensuring the bar puller operates reliably over time. By consistently applying these practices, manufacturers can achieve higher throughput, maintain uniform quality, and foster a safer, more efficient working environment.

Conclusion

A CNC lathe bar puller is an essential tool in modern machining operations. It enhances efficiency by automating bar extraction, improves workplace safety by reducing manual handling, and ensures consistent part quality. By choosing the right type of puller, installing it properly, and performing regular maintenance, manufacturers can achieve higher productivity, lower operational costs, and a safer working environment.

Bar pullers are now standard in high volume production facilities and precision machining shops. They demonstrate value across many industries. Investing in a quality device is more than a convenience. It is a strategic choice that supports long term efficiency, reliability, and operational excellence.

FAQs

What is a bar puller?

A bar puller is a device that automatically extracts bar stock from the lathe spindle after machining, reducing manual handling and improving cycle times.

How does a bar puller differ from a bar feeder?

A bar feeder continuously supplies raw material to the lathe, while a bar puller only removes the bar stock after machining. Together, they provide an automated workflow for high-volume production.

Can I install a bar puller on any lathe?

Not all lathes are compatible with bar pullers. Operators should verify spindle size, bar stock diameter, and manufacturer guidelines before installation to ensure proper functionality.

How often should a bar puller be maintained?

Maintenance should be performed every 3–6 months depending on usage. Lubrication of moving parts and inspection of gripping surfaces are essential for consistent performance.

What types of materials can a bar puller handle?

Most bar pullers work effectively with steel, aluminum, and brass. Specialized pullers may be required for brittle or exotic materials to prevent slippage and ensure safe extraction.