A CNC lathe conversion is a transformative project that can significantly enhance the capabilities of your home workshop. By upgrading a manual lathe with motors, drives, and a computer-controlled interface, machinists and hobbyists can achieve higher precision and repeatability in their projects. This type of upgrade allows for more complex parts and designs that would be difficult or time-consuming to produce manually. It opens up opportunities for efficiency and consistency that manual operation alone cannot provide.

For small-scale manufacturers and home machinists, this upgrade also provides valuable hands-on experience with modern machining techniques. The process combines mechanical, electrical, and software systems, offering both skill development and practical benefits. With proper planning, careful component selection, and attention to calibration, a converted lathe can become a reliable, high-performance tool for years to come.

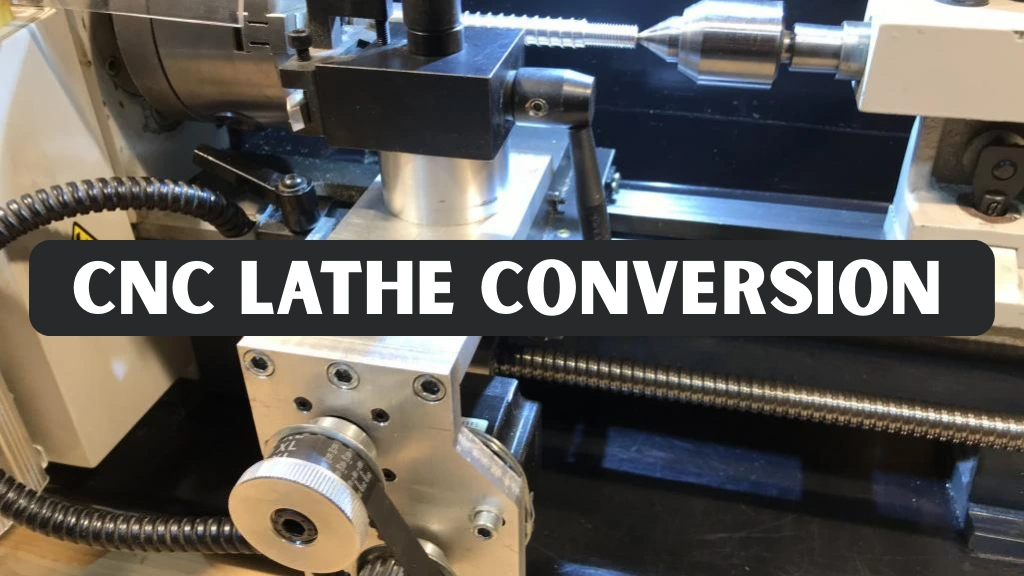

Introduction to CNC Lathe Conversion

Upgrading a traditional manual lathe with electronic components such as motors, drives, and a computer-controlled interface enables precise, automated control of the lathe’s movements along its axes. Unlike manual lathes, where every cut relies on direct human input, the upgraded lathe can perform repeated operations with consistent accuracy. This is especially valuable for producing multiple parts with identical specifications or creating complex geometries that would be difficult to achieve manually.

Undertaking a CNC lathe conversion goes beyond simply installing hardware; it requires integrating mechanical, electrical, and software systems to maximize efficiency, safety, and overall performance. By carefully understanding each component and process, machinists can ensure a successful upgrade that delivers long-term value to their workshop while enhancing their technical skills and practical experience.

Benefits of Converting to CNC

The advantages of upgrading a manual lathe are significant and multifaceted. One of the most notable benefits is increased precision. Automated control allows for tighter tolerances than manual operation, which reduces errors and improves part quality. This level of accuracy is especially valuable in industries like aerospace or automotive prototyping, where even minor deviations can impact functionality.

Enhanced productivity is another major benefit. Once the system is set up, the lathe can perform repetitive tasks autonomously, freeing the operator to focus on other aspects of production or run multiple machines simultaneously. For small home shops, this efficiency translates into completing more projects in less time without sacrificing quality.

A CNC lathe conversion also expands the types of work that can be performed. Intricate shapes, complex threads, and detailed patterns that would require extensive manual skill become achievable with automated control. Upgrading existing equipment is often more cost-effective than purchasing a new CNC lathe, making it an attractive option for hobbyists and small businesses. Additionally, the process helps operators develop valuable technical skills, including motor setup, G-code programming, and machine calibration, increasing their versatility and professional competence.

Planning Your CNC Conversion

Careful planning is crucial before beginning a CNC lathe conversion. The first consideration is lathe compatibility. Not every manual lathe is equally suited to conversion, and factors such as structural rigidity, size, and mechanical condition play a critical role. A lathe must be stable enough to handle automated movement without vibration or deflection, which could compromise accuracy.

Budget is another critical factor. CNC conversions require components such as motors, ball screws, linear guides, a control box, and appropriate software. Costs vary widely depending on whether you purchase a conversion kit or source individual components. Additionally, you may need specialty tools to complete the installation, such as alignment jigs or torque measuring equipment. Planning a realistic budget ensures that the project is financially feasible and reduces the risk of interruptions during installation.

Assessing your skill level is equally important. While some kits are designed for beginners, a successful conversion requires mechanical aptitude, basic electrical knowledge, and familiarity with computer interfaces. Understanding your limitations will help you determine whether to attempt a DIY conversion or seek assistance from an experienced technician.

Finally, consider the time commitment. Depending on the complexity of the lathe, the chosen components, and your experience, a conversion can take anywhere from a few weeks to several months. Allocating sufficient time ensures that you do not rush critical steps such as motor alignment, wiring, or calibration, which could impact performance.

Essential Components

Upgrading a manual lathe to a computerized system depends on a combination of mechanical and electronic components working together to automate motion. Stepper motors or servo motors drive the lathe along its axes, with servo motors preferred for heavier machines or high-speed, high-torque applications, while stepper motors are more affordable and suitable for smaller benchtop models.

Ball screws provide precise linear motion with minimal backlash, ensuring that the movement commanded by the software translates accurately to the machine. Linear guides support the carriage and tailstock, allowing smooth and stable travel along the lathe bed. Proper installation of these components is essential to avoid uneven movement or misalignment that could reduce accuracy.

Motor mounts and couplings securely attach the motors to the mechanical components, ensuring consistent transmission of motion without slippage. The control box houses the electronics, including motor drivers and interface boards, and serves as the central hub connecting the lathe to the computer. A stable and properly rated power supply delivers consistent voltage and current to the motors and control electronics. Finally, cables, connectors, and limit switches complete the system, ensuring proper communication between the computer, control box, and mechanical components.

Step-by-Step Conversion Process

The conversion process begins with disassembly of the lathe’s manual components. This includes removing handwheels, lead screws, and any existing gearboxes that may interfere with the installation of motors and ball screws. Careful labeling and organization of removed parts help prevent mistakes during reassembly.

Next, the motors and ball screws are installed on the lathe’s axes. Alignment is critical at this stage to minimize backlash and wear over time. Improper alignment can cause uneven cutting, increased vibration, and premature component failure. Once the motors are installed, linear guides are mounted along the lathe bed to support the carriage and tailstock, ensuring smooth movement.

The control box is then assembled, integrating motor drivers, the power supply, and interface boards. Wiring must follow proper diagrams, and insulation must be carefully applied to prevent electrical shorts or interference. After the mechanical and electronic components are installed, the system is connected to a computer running CNC control software.

Testing and calibration follow. Each axis should move smoothly and respond accurately to commands. Backlash compensation settings should be adjusted to reduce any play in the system, and different feed rates and spindle speeds should be tested to identify optimal operating conditions. Safety checks are also critical to ensure all emergency stops and limit switches function correctly.

Software and Control Systems

CNC control software is the interface between the user and the lathe. Popular options include Mach3, Mach4, and LinuxCNC. These programs interpret G-code commands, converting them into precise movements for the motors and axes. The software’s ability to handle various toolpaths, manage spindle speed, and coordinate multiple axes is essential for a successful conversion.

Choosing the right software involves considering compatibility with the motors, drivers, and control electronics. Some software packages also offer simulation tools to preview cuts before execution, which reduces the risk of errors or collisions. Online communities, tutorials, and manufacturer support can help beginners learn the software efficiently, ensuring a smoother learning curve.

Testing, Calibration, and Real-World Experience

Proper testing and calibration are essential for achieving optimal performance on a computerized lathe upgrade. In addition to verifying axis movement and compensating for backlash, operators should perform trial cuts on scrap material before working on final parts. Monitoring surface finish, dimensional accuracy, and tool wear helps identify whether additional adjustments are needed. Experience from home workshops and small-scale manufacturers shows that iterative testing and patience often yield better results than rushing through production.

Integrating sensors, such as limit switches or probe systems, enhances both safety and precision. These devices prevent the machine from exceeding its physical limits and provide real-time feedback that can automate processes like zeroing or tool measurement. Implementing these systems ensures consistent quality and reliability while protecting both the equipment and the operator.

Maintenance and Troubleshooting

Maintaining a CNC lathe after conversion is crucial for long-term performance. Regular lubrication of moving parts prevents wear and extends the lifespan of ball screws and guides. Cleaning debris from the lathe bed and motor assemblies prevents jams and electrical shorts. Software updates should be applied to benefit from improved features, bug fixes, and compatibility enhancements.

Troubleshooting issues often involves examining mechanical alignment, motor performance, wiring connections, and software settings. Many home machinists use online forums, tutorials, and professional technicians as resources for solving challenging problems. Keeping detailed records of calibration settings and maintenance schedules further enhances the machine’s reliability.

Conclusion

A CNC lathe conversion is a rewarding project that transforms a manual lathe into a precise, efficient tool for home workshops and small-scale production. By carefully planning, choosing quality components, and following a structured installation and calibration process, machinists gain practical experience in modern manufacturing. This project also develops technical skills and a deeper understanding of machine operation. With regular maintenance and proper care, a converted lathe can remain reliable for years while supporting a variety of projects.

For additional guidance, the article on Make: Magazine provides a real-world example of this type of conversion. It highlights hands-on insights, component selection, and solutions to common setup challenges. Readers can learn best practices from experienced machinists to ensure a successful and efficient conversion. This resource reflects trustworthy expertise and provides actionable advice for hobbyists and professionals alike.

FAQs

1. How much does a lathe conversion to CNC cost?

The cost varies depending on lathe size, component selection, and whether a conversion kit is used. DIY conversions typically range from $1,000 to $3,000, while professional kits may cost more.

2. Can any manual lathe be converted to CNC?

Most manual lathes can be converted, but success depends on the machine’s design, rigidity, and condition. Assessing compatibility before beginning the project is essential.

3. Do I need programming experience to operate a CNC lathe?

While basic knowledge of G-code is helpful, modern CNC software often provides user-friendly interfaces and tutorials that assist beginners in learning the operation efficiently.

4. How long does a conversion usually take?

Conversion time varies with complexity and experience. Generally, a project can take a few weeks to a couple of months from planning to fully operational status.

5. Can the lathe still operate manually after conversion?

Yes, many CNC conversions allow hybrid operation, letting users switch between manual and CNC modes when needed, offering flexibility for diverse machining tasks.