CNC lathes have become essential in modern manufacturing, combining automation, precision, and efficiency. The performance and reliability of these machines largely depend on the CNC lathe parts, with each component playing a crucial role in ensuring accuracy, speed, and durability.

For machinists, engineers, and workshop enthusiasts, a solid understanding of these parts can make the difference between smooth operation and frequent maintenance issues. This guide explores the main components, their functions, selection criteria, and maintenance practices, providing practical insights to maximize performance and longevity.

What is a CNC Lathe?

A CNC lathe, which stands for computer numerical control lathe, is a highly automated machine designed to shape materials such as metals, plastics, or wood. Unlike traditional lathes, CNC lathes operate based on pre-programmed instructions, allowing them to perform complex machining operations with remarkable precision. These machines can execute turning, threading, drilling, and facing tasks with consistent repeatability, reducing the variability associated with manual operations.

CNC lathes are widely used across industries such as aerospace, automotive, medical devices, and precision engineering. Their efficiency and output quality rely heavily on the proper functioning and maintenance of every CNC lathe part, ensuring smooth operation and long-term reliability.

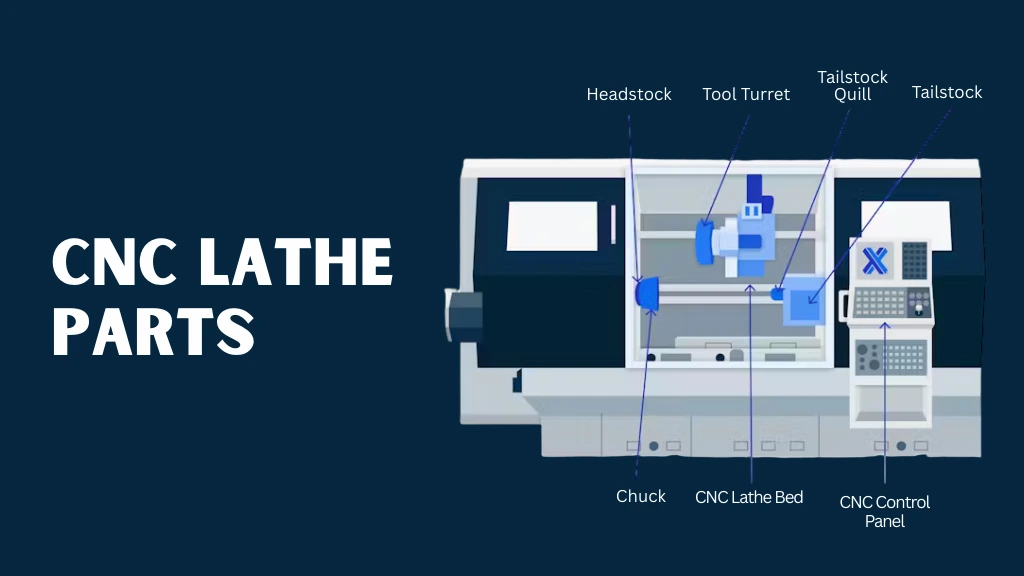

Key CNC Lathe Parts

The efficiency and accuracy of a CNC lathe are largely determined by the quality, alignment, and performance of its components. Each part has a unique function and is designed to work in concert with other components to ensure smooth operation.

Bed

The bed forms the foundational structure of a CNC lathe and is responsible for supporting all major components, including the headstock, tailstock, and carriage. Typically made from cast iron or steel, the bed is engineered for rigidity and vibration damping. A strong and stable bed ensures that all other components remain precisely aligned during machining operations, which is essential for maintaining tight tolerances. Regular cleaning and proper leveling of the bed are crucial maintenance practices. Over time, accumulation of chips or uneven leveling can lead to misalignment, which can adversely affect machining precision and part quality.

Headstock

The headstock is one of the most critical components of a CNC lathe. It houses the main spindle and the drive mechanism responsible for rotating the workpiece. Within the headstock, the spindle is supported by high-precision bearings, and a gearbox or variable-speed drive system provides the necessary speed and torque for different materials. Selecting a headstock that matches the machine’s intended workpiece size and material is crucial.

For example, machining hardened steel requires a high-torque headstock, while aluminum and other softer metals can be efficiently processed with moderate torque. Regular inspection and lubrication of headstock components are essential to maintain smooth rotation and prevent premature wear.

Tailstock

The tailstock provides additional support for long workpieces, preventing bending or vibration during machining. Tailstocks can be manually adjusted or CNC-controlled for automatic positioning. Accurate alignment of the tailstock is vital to ensure that long shafts or rods maintain dimensional precision throughout the operation. Regular maintenance, including cleaning, lubrication, and alignment checks, is necessary to prevent workpiece deflection. A properly functioning tailstock not only improves machining accuracy but also extends the life of cutting tools by reducing stress on the material.

Carriage Assembly

The carriage assembly is responsible for moving the cutting tool along the workpiece. It consists of the saddle, cross-slide, tool post, and apron, which contains the feed mechanisms. The carriage must move smoothly along the bed with minimal backlash to maintain high-precision machining. CNC-controlled carriages offer superior accuracy compared to manual versions, as they are programmed to follow precise paths at controlled speeds. Ensuring that the carriage slides and guides are clean, lubricated, and free of wear is essential for consistent part quality.

Tool Turret or Tool Post

The tool turret, or tool post, is designed to hold multiple cutting tools and allows for rapid tool changes during automated operations. There are various types, including fixed tool posts and rotary turrets, which can hold several tools simultaneously. Efficient tool management reduces downtime caused by manual tool changes and increases overall production speed. Modern CNC lathes often integrate advanced tool monitoring systems to detect tool wear and optimize replacement schedules, ensuring consistent quality and minimizing scrap rates.

Spindle

The spindle is a central component of the CNC lathe, responsible for rotating the workpiece and transmitting torque from the drive system. Selecting the appropriate spindle involves considering its speed, torque, and rigidity to match the material and dimensions of the workpiece. High-speed spindles are suitable for lighter materials such as aluminum, while low-speed, high-torque spindles are necessary for machining steel, titanium, or other hard materials. Proper spindle maintenance, including lubrication, bearing inspection, and alignment checks, is essential for achieving consistent accuracy and extending the life of the machine.

Chuck

The chuck is the component that secures the workpiece to the spindle. Common types include three-jaw self-centering chucks, which are ideal for round parts, and four-jaw independent chucks, suitable for irregularly shaped workpieces. Choosing the right chuck is critical for safety, precision, and workpiece stability. Regular inspection of the jaws and tightening mechanisms prevents slippage, ensures accurate machining, and reduces the risk of accidents. Proper chuck maintenance also contributes to the longevity of other CNC lathe parts by minimizing vibration and stress during operation.

Coolant System

The coolant system is essential for regulating temperature during cutting operations, preventing overheating, and extending the life of cutting tools. It circulates coolant through pumps, reservoirs, and nozzles to maintain consistent lubrication and cooling. Proper coolant management improves surface finish, reduces thermal expansion of the workpiece, and ensures stable cutting conditions. Ensuring that the coolant concentration and flow rate are optimized for each material enhances machining efficiency and prevents premature wear of the tools and machine components.

Ball Screws and Linear Guides

Ball screws convert rotary motion into precise linear movement, which drives the carriage and tool post. They are critical for achieving tight tolerances and smooth motion. High-quality ball screws reduce backlash and maintain alignment, contributing significantly to machining accuracy. Linear guides, which support and guide the movement of the carriage and cross-slide, work in tandem with ball screws to ensure stability and precision. Regular lubrication and inspection of these components are necessary to prevent wear, maintain smooth operation, and achieve consistent results across repeated production cycles.

CNC Control Panel

The CNC control panel serves as the interface between the operator and the machine, allowing programming, monitoring, and control of all operations. Modern control systems support G-code programming, touchscreen interfaces, and remote diagnostics. Industry-leading CNC control systems, such as those provided by Fanuc or Siemens, offer advanced features for tool monitoring, predictive maintenance, and error detection. A reliable control panel ensures accurate execution of machining programs, reduces operator error, and enhances overall productivity.

Selection Criteria

Selecting the right CNC lathe parts is essential for maximizing machine performance. Operators must consider material compatibility to ensure components can withstand the specific material being machined, whether steel, aluminum, brass, or plastic. Using parts that match the material requirements helps maintain machining quality and prevents premature wear.

The load capacity of each part must also be sufficient to handle operational torque, cutting forces, and rotational speeds. Precision components, including spindles, ball screws, and linear guides, directly affect the dimensional accuracy of machined parts. Choosing high-precision parts ensures consistent quality and reduces the risk of errors during production.

Durability is another critical factor when selecting parts. High-grade steel or cast iron components provide a longer operational life under continuous usage. Additionally, purchasing parts from reputable manufacturers guarantees access to technical support, documented quality standards, and warranties, providing peace of mind and reliability for long-term operations.

Maintenance Tips for Longevity

Routine maintenance of CNC lathe parts is essential to preserve their functionality and prevent unexpected downtime. Daily maintenance should include cleaning chips, checking coolant levels, and lubricating moving components. Weekly inspections should focus on the alignment of the headstock, tailstock, and tool post to ensure smooth and accurate operation.

Monthly checks involve evaluating ball screws, bearings, and electrical connections to identify early signs of wear. Annual maintenance may include replacing worn components, recalibrating axes, and performing a comprehensive inspection of the machine. Preventive maintenance not only ensures consistent part quality but also extends the life of critical components and reduces costly downtime.

Case Study

PrecisionTech Industries, a mid-sized automotive component manufacturer, faced frequent CNC lathe downtime and inconsistent part accuracy. Tool wear, spindle vibration, and workpiece slippage were affecting production quality. Inspection revealed worn spindle bearings, poorly lubricated ball screws, an outdated tool turret, and inconsistent coolant flow. These issues were directly reducing precision, efficiency, and reliability across operations.

To resolve these challenges, PrecisionTech upgraded spindle bearings and installed low-backlash, durable ball screws and linear guides. Engineers modernized the tool turret for faster automatic tool changes and calibrated the coolant system for optimal performance. Staff perform daily lubrication and weekly alignment checks. Dimensional accuracy improved by 35%, tool life increased by 40%, downtime fell by 25%, and surface finish quality met automotive standards.

Common CNC Lathe Issues and Solutions

CNC lathe machines can experience issues such as workpiece deflection, poor surface finish, vibration, and software errors. Tailstock misalignment often causes workpiece deflection, so operators should re-align the tailstock or use a steady rest. Worn cutting tools can cause a poor surface finish, so replace them and adjust feed and speed settings for optimal performance.

Loose carriage or spindle components typically cause excessive vibration, so operators should tighten or replace them. Software glitches or miscalibration can cause CNC errors, such as unexpected program interruptions, which technicians usually resolve through software updates and recalibration. Understanding these common issues and their solutions helps operators maintain consistent production quality and minimize downtime.

Conclusion

CNC lathes are complex machines that rely on the seamless integration of CNC lathe parts to operate efficiently. Each component, from the bed and spindle to the tool turret and coolant system, plays a critical role in achieving precision and productivity. Choosing high-quality parts, performing regular maintenance, and understanding their functions are key to long-term performance. Operators and engineers who prioritize the selection and upkeep of CNC lathe components can achieve superior machining results, reduce downtime, and ensure consistent production quality.

Investing in reliable CNC machine parts improves machine performance, and proper maintenance practices keep the lathe running smoothly. These actions increase operational efficiency in the workshop and boost profitability for any machining operation.

FAQs

What are the most critical parts of a CNC lathe?

The spindle, chuck, tool turret, ball screws, and control panel are the most vital components that influence machining precision and operational efficiency.

How often should Computer Controlled lathe parts be maintained?

Operators should clean and lubricate daily, check alignments weekly, inspect components monthly, and perform full maintenance annually to maintain optimal performance.

Can generic parts replace original CNC machine parts?

Generic components can be used if they meet the specifications of the original manufacturer. Using inferior parts may affect precision, reliability, and safety.

How do I choose the right chuck?

Selecting the correct chuck depends on the workpiece’s size, shape, and material. Use a three-jaw self-centering chuck for round parts, and a four-jaw independent chuck for irregularly shaped components.

What is the role of the coolant system?

The coolant system regulates temperature, extends tool life, prevents thermal expansion, and improves surface finish. Proper coolant flow and concentration are essential for consistent machining results.