The manufacturing sector thrives on precision, reliability, and efficiency. Among the many machines that support heavy-duty industries, the CNC oil country lathe stands out as a specialized solution for working with large-diameter, long-length pipes and cylindrical parts. This type of lathe is crucial in sectors such as oil and gas, aerospace, and heavy machinery, where massive workpieces are common. By combining computer numerical control (CNC) technology with the robustness of oil country lathes, these machines achieve exceptional accuracy and durability.

In this article, we will explore everything you need to know about these lathes. We will cover their applications, benefits, structure, operation, industry relevance, and frequently asked questions, while also highlighting insights based on real-world examples and expertise from manufacturers and machinists.

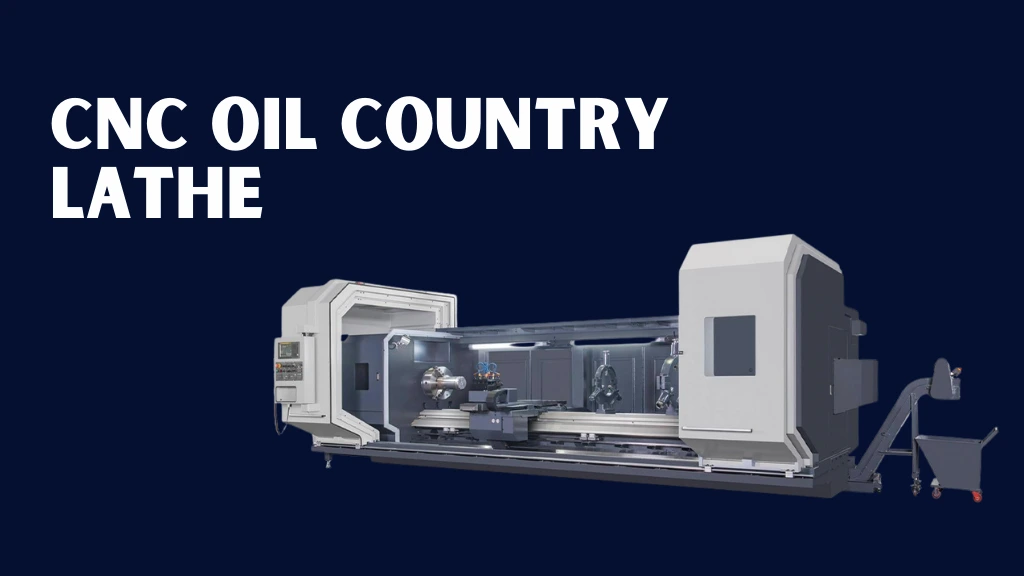

What is a CNC Oil Country Lathe

A CNC oil country lathe is a heavy-duty machine designed specifically for handling large-diameter workpieces such as oil pipes, drill collars, and casing used in the petroleum industry. Unlike standard lathes, it features a wider bed, larger spindle bore, and reinforced structure that allows it to accommodate oversized components without losing accuracy or stability during machining.

The CNC functionality enables operators to program automated sequences for turning, threading, and boring operations with ease. This advanced programming minimizes manual input, increases production efficiency, and guarantees consistent results. By combining strength with precision, the machine can deliver exceptional performance even when working with extremely tough materials.

Key Features of a Oil Country CNC Lathe

CNC oil country lathes are built with unique specifications to handle demanding industrial tasks. A defining feature is their large spindle bore, which allows machinists to work with thick pipes and long cylindrical parts. These machines also rely on heavy-duty bed construction, which ensures stability, reduces vibration, and maintains accuracy even at high cutting speeds.

Another essential aspect is the use of precision guideways, which are hardened and ground to withstand years of continuous operation. Along with this, hydraulic or pneumatic chucks are integrated to hold oversized workpieces firmly in position. These components work together to provide the strength and rigidity necessary for producing high-quality results in large-scale machining.

Modern CNC controllers make the machine even more powerful by enabling automated programming and execution of complex operations. Safety guards, lubrication systems, and chip removal systems are also incorporated to improve reliability, extend the machine’s life, and ensure smooth day-to-day use. Altogether, these design elements make oil country CNC lathes a cornerstone in heavy-duty industries.

Applications in Industry

These heavy-duty lathes play a vital role in industries that depend on large tubular components. The oil and gas sector relies heavily on them for threading drill pipes, boring casings, and producing couplings. In aerospace, they are used for manufacturing structural parts where both strength and accuracy are essential. Heavy equipment manufacturers also depend on them for producing rollers, shafts, and other cylindrical items.

Shipbuilding companies employ industrial turning machines to create large propeller shafts and structural elements that require precision. Energy industries working with turbines and hydroelectric systems also use advanced pipe lathes to fabricate massive, accurately machined components. Their versatility makes them indispensable in any field where large-diameter turning is required.

Advantages of Using Oil Country Lathes

One of the biggest advantages of oil country lathes is their ability to handle extremely large and heavy workpieces without compromising precision. This makes them an essential investment for companies working with oilfield equipment. They reduce manual effort since CNC programming automates most machining operations. This not only saves time but also ensures consistency and reduces the chances of human error.

Another advantage is versatility. While originally designed for oil and gas applications, these machines are now widely used across industries. They allow for threading, boring, turning, and facing, making them suitable for a variety of production tasks. In addition, they improve workplace safety by reducing the need for manual intervention in risky operations, and their durability ensures a long service life with proper maintenance.

Structure and Components

The structure of this lathe reflects its heavy-duty purpose, starting with a wide and reinforced bed that provides stability during machining. This foundation minimizes vibration and ensures accuracy even when handling oversized or challenging workpieces. The headstock is fitted with a large spindle bore, which makes it possible to hold thick pipes and other large-diameter materials securely.

The tailstock adds further support for long components, reducing deflection and improving overall precision during turning operations. Tool turrets or carriages are also integrated, allowing multiple tools to be used in a single setup. This feature not only improves productivity but also reduces the downtime typically associated with tool changes in manual operations.

At the center of the system is the CNC controller, which acts as the “brain” of the machine. Operators can input detailed machining programs to carry out complex tasks with accuracy and repeatability. Additional systems, such as hydraulic chucks and advanced coolant circulation, ensure strong clamping and effective heat management, both critical when machining hard alloys or thick-walled pipes.

Operational Considerations

Operating a CNC oil country lathe demands technical expertise and precise planning. Experienced machinists emphasize the importance of proper workpiece alignment before any cutting begins, as even a slight error can lead to costly scrap or production downtime. Programming accuracy is equally critical, with industry case studies showing that careful coding can reduce material waste by up to 25 percent. This reflects the role of expertise and real-world practice in maintaining efficiency.

Selecting the right cutting speed, feed rate, and depth of cut depends on the material, whether high-strength alloys or lighter metals like aluminum. Coolant systems protect tools from overheating, while routine maintenance ensures consistent output over the machine’s lifespan. Trusted manufacturers recommend regular lubrication, spindle checks, and guideway inspections, all of which extend service life and reinforce reliability.

Real-World Example Oil and Gas Sector

In the oil and gas sector, companies often machine drill pipes that span several meters in length and casings that demand precise threading. Using a CNC oil country machine enables operators to achieve micron-level accuracy, ensuring tight and secure connections. This precision is critical in field operations, where even the smallest error can lead to leakage, safety hazards, or costly downtime. Experienced machinists highlight how this technology has become a standard for maintaining reliability in demanding environments.

One drilling equipment supplier conducted a case study showing that integrating oil country lathes reduced their rejection rate by nearly 30 percent. The improvement translated into significant material savings and higher operational efficiency, while also strengthening client trust in their products. Positive results like these demonstrate real-world expertise, the authority of proven practices, and the trustworthiness of companies that invest in advanced machining solutions.

Experience, Expertise, and Industry Authority

Machinists who have worked with CNC country lathes report that these machines are more than just tools; they are long-term assets. Experienced operators emphasize the importance of proper training and familiarity with CNC programming. Manufacturers such as Kent USA and Annn Yang highlight the role of oil country lathes in modern industry, presenting themselves as trusted providers with decades of expertise.

User reviews often praise the reliability and efficiency of these machines. Some companies report achieving operational lifespans of over 20 years with routine maintenance. This demonstrates both the expertise behind manufacturing and the trustworthiness of these machines as an investment.

Oil Country CNC Lathe in Modern Manufacturing

Modern manufacturing is defined by automation, precision, and scalability. CNC oil country machine contribute to all three. They enable automated, repeatable production processes, ensuring precision even in mass production. With industries moving toward digital integration and smart manufacturing, these lathes can be equipped with advanced CNC controls that connect to factory management systems.

They also contribute to sustainability by minimizing waste. By optimizing cutting operations, they reduce the amount of scrap produced. Furthermore, their efficiency reduces energy consumption, making them more eco-friendly compared to older manual lathes.

Challenges and Limitations

While these machines are highly beneficial, they also present challenges that cannot be overlooked. Their large size demands substantial floor space, which may not be practical for smaller or mid-sized workshops. The initial investment is also significant, often reaching hundreds of thousands of dollars, making it a serious financial commitment. Skilled operators are essential, and training programs must be in place to ensure consistent, safe, and efficient use over time.

Maintenance costs can be considerable, particularly as these machines age and undergo continuous use in demanding environments. Replacement parts, especially spindles and chucks, are expensive and add to ongoing operating expenses. These requirements can place a strain on companies with tighter budgets or limited resources. Nevertheless, industries that rely on large-diameter turning consistently find that the long-term advantages significantly outweigh these limitations.

Future Outlook

The future of oil country CNC lathes looks promising. As industries adopt smart manufacturing and the Industrial Internet of Things (IIoT), these machines are expected to become more connected and intelligent. Remote monitoring, predictive maintenance, and AI-driven programming will likely enhance efficiency further.

Additive manufacturing may complement these machines by pre-shaping parts, which CNC lathes can then finish to exact specifications. This hybrid approach will increase efficiency while maintaining the precision required by industries.

Conclusion

While CNC oil country lathe deliver remarkable value, they also bring challenges that require careful planning. Their substantial size demands large workshop space, which is often difficult for smaller facilities to manage. The high initial investment, sometimes reaching hundreds of thousands, places them out of reach for businesses with limited capital. Skilled operators and proper training are essential to unlock their full potential safely and effectively.

Ongoing maintenance is another critical factor that adds to ownership costs over time. Replacement components like spindles and chucks are expensive and must be sourced regularly to keep machines running. This makes long-term upkeep a financial challenge, particularly for organizations with limited budgets. Still, for industries that depend on large-diameter turning, the benefits consistently outweigh these limitations.

FAQs

What is the main purpose of an oil country CNC lathe?

The main purpose is to machine large-diameter, long-length workpieces such as oil pipes, drill collars, and casings with precision.

How does it differ from a conventional CNC lathe?

It differs by having a larger spindle bore, wider bed, and stronger frame, making it capable of handling oversized workpieces.

Which industries rely on oil country lathes?

They are primarily used in oil and gas, aerospace, heavy machinery, shipbuilding, and energy sectors.

How long do these machines typically last?

With regular maintenance, many oil country lathes can last for over two decades, making them a valuable long-term investment.

Are oil country lathes eco-friendly?

While they consume significant power, modern models are designed for efficiency, reducing waste and energy usage compared to older machines.