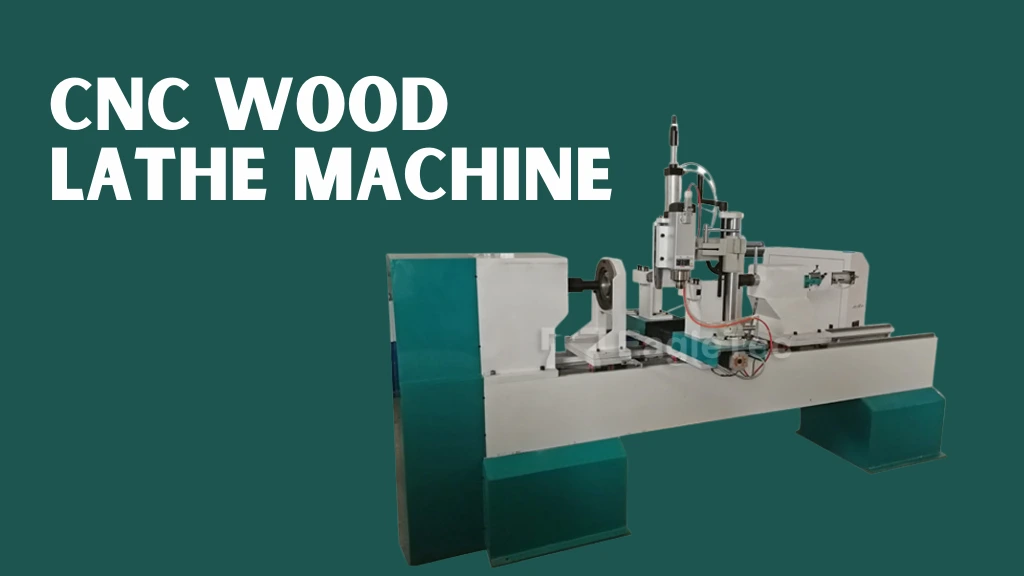

A CNC wood lathe machine represents one of the most significant advancements in modern woodworking. Unlike traditional lathes that depend heavily on manual adjustments, this technology uses computer control to deliver precision, repeatability, and intricate detailing. From small workshops to large-scale furniture manufacturing facilities, these machines are transforming production with their ability to balance accuracy, efficiency, and creative freedom.

This comprehensive guide explores everything you need to know about Computer controlled wood lathes, from how they work to their key features and benefits. You will also learn about real-world applications, buying considerations, essential maintenance practices, and emerging industry trends. Whether you are a hobbyist, a professional woodworker, or a business owner, understanding this technology will help you make informed decisions and stay competitive in the woodworking industry.

What is a CNC Wood Lathe Machine?

A CNC wood lathe machine is a computer-controlled tool that automates traditional woodworking operations with exceptional accuracy. By integrating CNC (Computer Numerical Control) technology, it can perform turning, grooving, carving, and sanding with minimal human involvement. This automation not only saves time but also ensures consistency across multiple pieces, making it highly effective for both small workshops and large-scale manufacturing.

The process starts with a design created in CAD (Computer-Aided Design) software, which is then converted into machine-readable instructions through CAM (Computer-Aided Manufacturing) software. These commands are sent to the CNC controller, which directs the lathe to carry out each task with precision. The result is reduced manual labor, improved efficiency, and guaranteed uniformity, making CNC wood turning machines an excellent choice for businesses focused on scalability and quality.

Working Principle of a CNC Lathe for Wood

The process begins with design creation, where a 2D or 3D model is drafted using CAD software and then converted into precise instructions through CAM programs. Once the wooden stock is mounted on the spindle, the CNC controller executes the programmed commands automatically. As the spindle rotates, tools perform cutting, carving, or shaping without the operator needing to constantly adjust angles or tool positions.

Advanced models of the CNC wood lathe machine enhance this workflow by integrating additional functions such as sanding, drilling, and polishing. This allows a fully finished product to be produced directly from the machine, reducing the need for manual intervention. The seamless process minimizes errors, ensures repeatability, and significantly boosts efficiency. For workshops of any scale, this automation transforms production while maintaining accuracy and consistency.

Key Features of CNC Wood Turning Lathe Machine

One of the standout features of CNC wood lathe machines is their precision and reliability. These machines are built to deliver identical results across hundreds of products, making them essential in industries where consistency matters. Multi-axis operation adds to their capability by allowing spindles to rotate while cutting tools carve, enabling complex designs in less time. Automation further boosts productivity by running with minimal supervision, which helps reduce labor costs.

Versatility and ease of use are equally important characteristics of modern computer-controlled wood turning machines. They can handle tasks such as bowl turning, spindle shaping, engraving, and decorative detailing, making them suitable for diverse applications. User-friendly interfaces, often featuring touchscreen panels and intuitive software, simplify setup and operation. This makes the machines accessible not only to professionals but also to beginners exploring advanced woodworking techniques with confidence.

Benefits of Computer-Controlled Wood Lathes

The benefits of adopting CNC wood lathes go well beyond basic precision, making them an essential tool in modern woodworking. One of the most significant advantages is higher productivity, as these machines can operate continuously with minimal supervision. By automating repetitive processes, manufacturers can produce larger volumes of work in less time, giving them a competitive edge in meeting growing market demands.

Equally important are the consistency and accuracy these machines provide. A CNC lathe produces identical results across multiple pieces, which is crucial for applications such as furniture manufacturing and architectural detailing where standardization matters. Precision programming also reduces material waste by ensuring every cut and carve follows exact specifications, saving both resources and costs in the long run.

While the upfront investment in CNC equipment may seem high, the long-term benefits make it a worthwhile choice. Businesses gain from fewer errors, lower labor requirements, and reduced waste, all of which translate into significant cost savings over time. At the same time, CNC technology expands creative opportunities, enabling woodworkers to design intricate and complex patterns that are difficult to achieve manually. This unique blend of efficiency, precision, and artistic flexibility makes computer-controlled wood lathes a smart and lasting investment for the woodworking industry.

Applications of CNC Wood Turning Machine

CNC wood lathes play a crucial role in furniture manufacturing by producing components such as chair legs, table spindles, and bedposts with consistent precision and quality. They are equally valuable in the home décor sector, where artisans use them to craft bowls, candlesticks, and decorative vases. In the sports industry, these machines provide the accuracy needed to manufacture baseball bats and other rounded wooden equipment that must meet performance standards.

Their applications also extend into architecture and custom woodworking. CNC lathes are widely used to create stair railings, decorative columns, and intricate wooden trims that add elegance to buildings. At the same time, custom woodworking businesses rely on them to deliver unique, personalized designs quickly and efficiently. With rising consumer demand for bespoke furniture and artistic wooden products, CNC technology is helping workshops achieve both creativity and scalability.

Buying Guide: What to Consider Before Purchasing

Investing in a CNC wood lathe requires careful planning to ensure the machine meets your production goals. The size and capacity should align with your workload, as large-scale operations often need heavy-duty equipment for processing bigger stock, while smaller workshops can operate efficiently with compact models. Software compatibility is equally important, since seamless integration with CAD and CAM programs makes design and production smoother.

The machine’s number of axes plays a major role in determining its versatility. Two-axis models are generally sufficient for basic turning operations, but workshops aiming for intricate designs often benefit from four-axis or higher machines. Build quality is another critical factor, as units constructed with heavy-duty steel frames usually provide greater durability and stability under continuous use.

Beyond technical specifications, buyers should also evaluate after-sales support, training, and long-term value. Manufacturers that offer technical assistance, comprehensive manuals, and responsive service help maximize productivity and minimize downtime. Pricing is another major consideration, with entry-level machines starting at a few thousand dollars, while advanced industrial-grade systems can reach tens of thousands.

Maintenance and Care

Regular maintenance is vital for ensuring the longevity and consistent performance of the machine. Daily cleaning should be carried out to remove sawdust and wood chips, as buildup in moving parts can restrict motion and reduce efficiency. Lubricating spindles, guides, and bearings at scheduled intervals helps maintain smooth operation and minimizes unnecessary wear. Sharp cutting tools are equally important, as dull or damaged tools increase machine stress and compromise finish quality.

In addition to mechanical care, accuracy and software upkeep play key roles in maintenance. Periodic alignment checks and recalibration keep the machine precise, which is essential for professional woodworking applications. Updating software ensures compatibility with the latest design systems and enhances operational performance. From my experience, workshops that consistently follow these steps avoid costly downtime and extend machine lifespan. A disciplined maintenance routine ultimately protects both productivity and investment.

Industry Trends

The CNC woodworking industry is advancing quickly, driven by artificial intelligence and Internet of Things (IoT) integration. These technologies make predictive maintenance and remote monitoring possible, reducing downtime and improving efficiency. From real-world adoption cases, workshops using IoT-enabled CNC wood lathes achieve smoother operations and better output. Multi-axis CNC machines are also gaining popularity, enabling the production of complex and detailed woodworking designs.

Custom woodworking and sustainability are driving key trends in the industry, with consumers seeking unique furniture and decorative products. Workshops are adopting CNC machines for precision customization while reducing material waste to support eco-friendly practices. Research shows that combining automation with sustainable methods strengthens business reputations and long-term success. These developments demonstrate that computer-controlled wood turning machines will continue to play a central role in modern woodworking.

Case Study Example

A mid-sized furniture manufacturer upgraded from manual lathes to a computer-controlled wood turning machine, and within a year saw a 40% increase in production efficiency and a 25% reduction in labor costs. Customers observed improvements in consistency and design quality, resulting in more orders and an expanded market presence. Profits rose accordingly, illustrating the strong return on investment that companies can achieve by adopting automated wood turning technology.

Conclusion

The CNC Wood Lathe Machine has transformed woodworking by combining automation with unmatched precision. Its ability to produce intricate, repeatable, and high-quality designs makes it an essential tool for workshops, furniture makers, and industrial manufacturers. While the initial cost may be high, the long-term benefits in productivity, cost savings, and design flexibility make it a smart investment. As the industry continues to evolve, computer-controlled wood turning machines will remain central to woodworking innovation, enabling professionals and hobbyists to expand their capabilities and achieve superior results.

FAQs

What is the difference between a CNC wood and a manual lathe?

A Computer Control wood lathe automates the turning process, while a manual lathe requires constant operator control. The CNC machine ensures higher precision and faster production.

How much does a computer-controlled wood turning machine cost?

Costs vary depending on size, features, and brand. Small entry-level machines may cost around $2,000, while industrial versions can exceed $20,000.

Can beginners use a CNC wood machine?

Yes. With proper training, beginners can operate computer-controlled wood turning machines thanks to their intuitive software and automated features.

Which industries benefit most from CNC wood turning machines?

Sectors like furniture production, home décor, architecture, and sports equipment gain major advantages from automated wood turning machines.

What to consider when buying an automated wood turning machine?

You should evaluate your production scale, available workspace, required design complexity, and budget when selecting the right machine.