In today’s manufacturing environment, precision, speed, and efficiency are more important than ever. Traditional lathes, while reliable, often require multiple setups to complete complex parts, which can slow production and introduce errors. The Dual Spindle CNC Lathe has emerged as a solution to these challenges, offering manufacturers the ability to machine both sides of a workpiece in a single continuous operation. By combining advanced automation with precision engineering, these machines significantly reduce cycle times while ensuring consistent quality.

Whether you operate a small workshop, a mid-sized production facility, or a large-scale industrial operation, understanding the benefits and applications of dual spindle lathes can help you optimize operations, reduce costs, and improve competitiveness. This guide explores how these machines work, the advantages they provide, real-world applications, and critical factors to consider before investing.

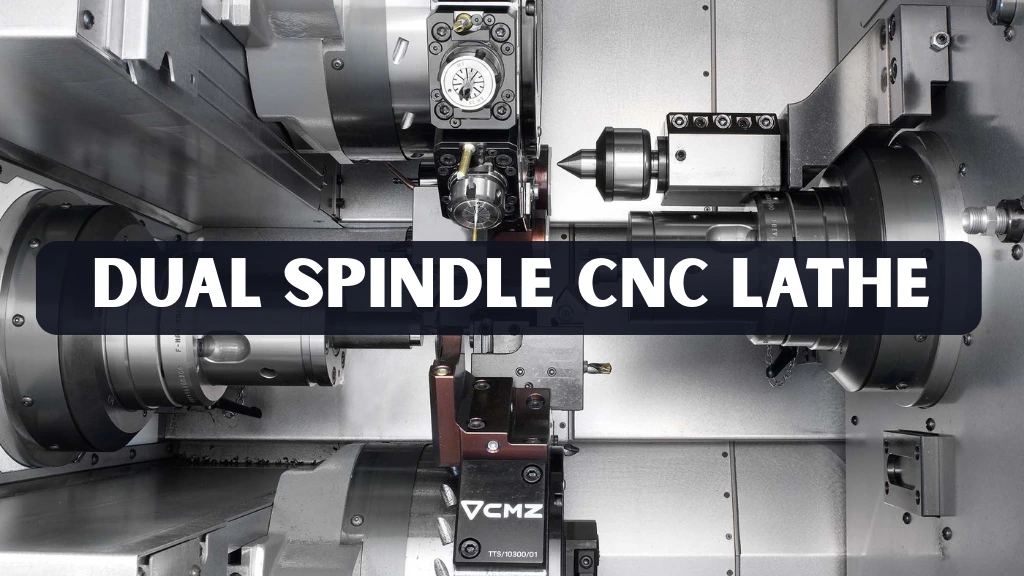

What is a Dual Spindle CNC Lathe

A Dual Spindle CNC Lathe is a computer-controlled turning machine equipped with two spindles: a main spindle and a sub-spindle. The main spindle performs the initial machining operations, such as turning, facing, drilling, or threading. After this first operation is complete, the sub-spindle automatically receives the workpiece and performs secondary operations on the opposite side.

This automated transfer eliminates the need to manually reposition the part, which is often necessary with single-spindle lathes. As a result, manufacturers experience not only faster production but also reduced chances of alignment errors, which translates into better overall precision and lower scrap rates. Dual spindle lathes are commonly used for high-volume production runs where consistency and speed are essential.

Productivity Gains with Advanced CNC Turning

One of the most compelling reasons to invest in a dual spindle lathe is the substantial increase in productivity. By machining both sides of a workpiece in a single cycle, manufacturers can produce more parts per hour without sacrificing quality. Unlike single-spindle lathes, which require multiple setups and frequent handling, dual spindle machines allow operators to focus on other critical tasks while the machine completes the entire operation automatically.

In addition, the automated workpiece transfer reduces the need for operator intervention, which not only saves labor costs but also minimizes human errors. Shops that previously relied on multiple single-spindle machines can now consolidate operations, freeing up floor space and simplifying workflow. Over time, this increased efficiency contributes directly to higher output and profitability.

Precision and Consistency in Manufacturing

Precision is crucial in industries such as aerospace, automotive, and medical device production, where even small deviations can lead to product failures or safety risks. Dual spindle lathes ensure that parts are machined to exact specifications by eliminating the need to manually reposition the workpiece.

The sub-spindle takes over seamlessly after the main spindle completes its operation, allowing the opposite side of the component to be machined with the same accuracy. This continuity improves dimensional consistency across production batches, reduces scrap, and enhances overall quality control. Companies benefit from fewer rejected parts and more reliable product performance, which strengthens customer trust and satisfaction.

Cost Efficiency and Long-Term ROI

While the initial investment in a dual spindle lathe is higher than for a single-spindle machine, the long-term return on investment often outweighs the upfront cost. Manufacturers save money in several ways. First, reduced setup times and automated transfers cut down labor requirements, freeing skilled operators to handle more complex tasks or multiple machines. Second, the enhanced accuracy lowers scrap rates and reduces the need for rework. Finally, the streamlined production process helps extend tool life, since cutting operations are smoother and more consistent.

Over a period of months to years, these efficiencies typically offset the initial expenditure. Companies that previously struggled with meeting deadlines or producing high-volume orders find that dual spindle lathes provide both financial and operational benefits, making the investment worthwhile.

Applications Across Key Industries

Dual spindle CNC lathe are used in a wide range of industries where speed, precision, and repeatability are essential. In the automotive sector, they are ideal for machining transmission shafts, brake components, and gear housings. These parts require tight tolerances and must be produced in large quantities to meet demand, making dual spindle systems a natural choice.

In aerospace manufacturing, dual spindle lathes are employed to produce turbine blades, landing gear parts, and structural fittings. The consistency and precision these machines offer are critical to meeting rigorous safety and performance standards.

Medical device manufacturers rely on dual spindle lathes to produce surgical instruments, orthopedic implants, and dental components. The ability to produce complex geometries with minimal deviation ensures that medical products meet strict regulatory standards.

The electronics and energy sectors also benefit from these machines. Components such as housings, connectors, and specialized fittings require high-precision machining, and dual spindle lathes allow manufacturers to meet these requirements efficiently while maintaining consistent quality across large production runs.

Comparing Single and Dual Spindle Machines

When evaluating whether to invest in a dual spindle lathe, it is helpful to compare it with traditional single spindle models. Single spindle lathes can produce high-quality parts, but they are generally limited to machining one side of a workpiece at a time. This limitation requires additional setups, which increases cycle time and introduces the possibility of alignment errors.

Dual spindle machines, by contrast, allow both sides to be completed in a single continuous cycle. This capability results in significantly shorter production times, higher throughput, and greater consistency. While single spindle lathes may be more appropriate for low-volume or highly customized production runs, dual spindle systems are better suited for high-volume, repeatable manufacturing where efficiency and precision are priorities.

Real-World Example of Efficiency Gains

A mid-sized U.S.-based automotive supplier decided to upgrade from single-spindle CNC lathes to dual spindle machines for producing gear shafts. Within six months of implementation, the company reported a 35 percent reduction in cycle time and a noticeable drop in scrap rates. The faster production allowed the supplier to fulfill orders more quickly, increasing customer satisfaction and overall competitiveness.

Similarly, a medical device manufacturer in Germany adopted dual spindle lathes to produce orthopedic implants. The automated operation reduced the need for manual inspection and repositioning, which not only improved accuracy but also freed technicians to focus on more complex assembly tasks. These examples demonstrate how real companies benefit both operationally and financially from investing in dual spindle CNC technology.

Factors to Consider Before Purchasing

When considering a dual spindle CNC lathe, several factors should guide your decision. First, evaluate the size and capacity of the machine relative to the parts you typically produce. The lathe must accommodate the diameter, length, and complexity of your workpieces.

Second, the control system is critical. Most dual spindle machines use FANUC, Siemens, or Mitsubishi controllers. Ensuring compatibility with your existing software and programming expertise will reduce the learning curve and allow for smoother integration.

Tooling options also play a major role. Check whether the lathe includes live tooling for secondary operations like milling or drilling. The number of available tool stations and the speed of tool changes can directly affect cycle times and overall productivity.

Automation potential is another consideration. If your goal is lights-out manufacturing or minimal operator intervention, confirm that the machine can integrate with bar feeders, robotic arms, and conveyor systems. Finally, analyze the cost versus potential ROI. Although prices typically range from $90,000 to $250,000, the long-term savings in labor, scrap, and production time often justify the investment.

Leading Manufacturers

Several manufacturers are recognized globally for producing reliable and high-performance Dual Spindle turning centers. Mazak is known for its innovation and automation-friendly machines, while DMG MORI offers German-Japanese engineering renowned for precision. Haas Automation provides cost-effective solutions suitable for North American markets, and Doosan equipment is valued for durability and consistency across Asia and Europe.

TsinfA is a global supplier that offers customizable machining centers, catering to specific production needs. Choosing a reputable supplier ensures access to reliable spare parts, technical support, and operator training, all of which are critical for long-term operational success and continuity.

Business Benefits of Dual Spindle Systems

Upgrading to a double spindle CNC lathe provides several strategic benefits for businesses. Faster production cycles increase the number of parts produced per day, enabling companies to meet higher demand without adding additional labor. Reduced dependency on manual labor decreases the risk of human error and frees skilled operators for more complex tasks.

Consistency in part quality also strengthens customer trust, as clients receive reliable, defect-free components. Over time, these advantages improve a company’s competitiveness in domestic and international markets, particularly in industries where precision and efficiency are key differentiators.

Conclusion

The Dual Spindle CNC Lathe represents a significant advancement in modern manufacturing. By enabling both sides of a part to be machined in a single cycle, these machines improve efficiency, precision, and productivity. Industries from aerospace to medical devices rely on dual spindle systems to meet rigorous quality standards while maintaining high-volume production.

For manufacturers seeking long-term cost savings, higher throughput, and consistent product quality, investing in a dual spindle lathe is a strategic decision that can strengthen competitiveness and support future growth. By carefully considering capacity, tooling, control systems, and automation potential, businesses can ensure they select a machine that delivers measurable operational benefits.

FAQs

What is the difference between dual spindle and twin spindle lathes?

These terms refer to the same type of machine. Both involve two spindles that allow simultaneous machining of both sides of a workpiece in a single continuous operation.

How much does a twin spindle CNC lathe cost?

The cost typically ranges between $90,000 and $250,000, depending on machine size, features, and brand.

Are these machines suitable for small workshops?

Yes. Even small-scale operations can benefit from reduced cycle times, improved accuracy, and lower scrap rates, which can justify the investment.

Which industries rely most on these machines?

Automotive, aerospace, medical devices, electronics, and heavy machinery sectors are the primary users.

Can double spindle CNC lathes be integrated with automation systems?

Yes. Most modern designs support integration with bar feeders, robots, and conveyors for fully automated, lights-out production.