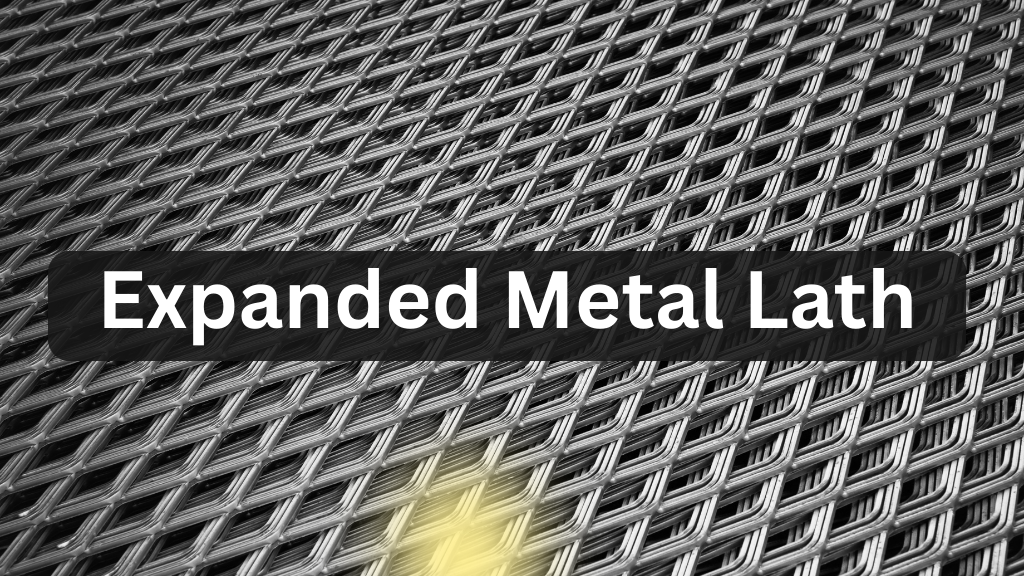

Expanded metal lath is a fundamental material in modern construction, offering unparalleled strength, flexibility, and durability. Widely used in plastering, stucco applications, and reinforcement, it has become indispensable for both residential and commercial projects. This comprehensive guide explores everything you need to know about expanded metal lath, including its types, applications, benefits, installation tips, maintenance, and frequently asked questions. By the end of this guide, construction professionals, contractors, and DIY enthusiasts alike will understand why this material is a cornerstone of strong and long-lasting structures.

What Is Expanded Metal Lath?

Expanded metal lath is a versatile mesh material made by slitting and stretching a solid sheet of metal, usually steel, to create a diamond-shaped pattern. This process transforms a flat sheet into a strong, lightweight mesh that is highly adaptable for different construction needs.

The unique design of expanded metal lath ensures excellent adhesion for plaster, stucco, and other coatings. The open diamond-shaped pattern allows materials to anchor securely, which reduces the risk of cracks and structural weaknesses over time. Beyond its mechanical benefits, expanded metal lath also provides ventilation, moisture resistance, and flexibility, making it suitable for both interior and exterior applications.

Types of Expanded Metal Lath

Choosing the right type of lath is critical to the success of a construction project. Below are the main types used in the industry:

1. Standard Expanded Metal Lath

Standard expanded lath is the most commonly used type. It features a uniform diamond pattern and provides a solid base for plaster and stucco applications. This type is ideal for walls, ceilings, and other structural surfaces that require strength and even adhesion.

2. Self-Furring Expanded Metal Lath

Self-furring lath is designed with raised edges that automatically create spacing between the lath and the substrate. This eliminates the need for additional furring strips, saving time and labor during installation. The raised design ensures that plaster bonds evenly and creates a more uniform finish.

3. Paper-Backed Expanded Metal Lath

Paper-backed lath comes with an integrated moisture-resistant paper backing. This feature enhances durability, particularly in exterior applications where weather exposure is a concern. The paper layer prevents moisture from seeping through the lath and protects the underlying substrate.

4. Flattened Expanded Metal Lath

Flattened expanded lath is created by cold-rolling the standard mesh to make it thinner and smoother. This variant is often used in applications that require a refined surface, such as ceilings, decorative features, and interior wall finishes.

5. Galvanized vs. Non-Galvanized Lath

Metal lath can be either galvanized or non-galvanized. Galvanized lath is coated with zinc to resist corrosion, making it suitable for exterior or high-moisture environments. Non-galvanized lath is more cost-effective but is generally limited to dry, indoor applications.

Applications of Expanded Metal Lath

Expanded metal lath has a wide range of applications in modern construction. Its versatility makes it a valuable tool in multiple industries.

-

Plaster and Stucco Base

The primary use of lath is as a base for plaster and stucco. The diamond-shaped mesh provides a secure surface for plaster to adhere to, ensuring a strong, long-lasting finish. This is especially important in exterior wall applications where weather and environmental stress can cause cracks if the plaster is poorly bonded.

-

Reinforcement in Concrete

In concrete applications, expanded lath acts as a reinforcement layer. It improves structural integrity by distributing weight and stress evenly, helping prevent cracks and shrinkage. This makes it a preferred choice for floors, walls, and ceilings that require both strength and flexibility.

-

Fireproofing

Expanded lath plays an essential role in fireproofing structures. Fire-resistant coatings can be applied directly onto the lath, which supports them and ensures even coverage. This added layer of protection is particularly useful in commercial buildings, industrial facilities, and high-rise constructions.

-

Acoustic Control

Another key application is acoustic control. Metal lath can support soundproofing panels and coatings, reducing noise transmission between rooms or floors. This makes it ideal for theaters, offices, schools, and other environments where noise management is critical.

-

Decorative and Architectural Features

Flattened and patterned metal lath can be used in interior design and architectural features. Designers use it for ceiling panels, decorative wall accents, and textured surfaces, combining functionality with aesthetics.

Benefits of Using Expanded Metal Lath

Expanded metal lath provides numerous advantages that make it an essential choice in modern construction. From durability and strength to cost savings and versatility, its benefits extend across residential, commercial, and industrial projects.

-

Enhanced Durability

The steel mesh design of metal lath creates a sturdy foundation that can support heavy plaster, stucco, or concrete layers. Unlike weaker alternatives, it resists wear and tear over time, ensuring structures maintain their integrity. Its long lifespan makes it highly reliable for both interior and exterior use.

-

Superior Adhesion

The diamond-shaped openings allow plaster and stucco to grip the lath securely, preventing separation or weak bonding. This ensures coatings remain firmly attached even under environmental stress. Builders favor it because it consistently produces smooth, professional finishes.

-

Crack Resistance

Lath distributes stress evenly across surfaces, reducing the chances of cracking in plaster or stucco layers. This is especially important for exterior walls that expand and contract with temperature changes. By minimizing cracks, it extends the lifespan of the surface finish.

-

Moisture Protection

Galvanized and paper-backed options provide added resistance against rust and moisture infiltration. This makes expanded metal lath a reliable choice in damp environments, such as basements, bathrooms, or exterior walls exposed to rain. The protective layer helps prevent costly long-term damage.

-

Time and Labor Savings

Self-furring expanded metal lath is designed to create spacing automatically, eliminating the need for extra furring strips. This speeds up the installation process and reduces labor costs significantly. Contractors often choose it for large projects where efficiency is critical.

-

Cost-Effectiveness

Although the upfront cost of expanded metal lath may be slightly higher than alternatives, its long-term savings are considerable. Its strength and low maintenance reduce the need for repairs and replacements. For builders and property owners, it provides an excellent return on investment.

-

Design Flexibility

Expanded metal lath can be cut, bent, and shaped to fit complex surfaces, including arches, curves, and corners. This flexibility allows architects and builders to achieve unique designs without compromising strength. It is widely used in both functional builds and decorative projects.

-

Environmental Resistance

One of the standout qualities of expanded metal lath is its ability to perform under harsh conditions. It withstands fluctuations in temperature, humidity, and chemical exposure. Whether in coastal regions, industrial zones, or dry climates, it delivers consistent reliability.

Installation Tips of Expanded Metal Lath

Proper installation of expanded metal lath is crucial to ensuring durability and maximizing performance. Following best practices helps achieve consistent results while minimizing issues like cracks or weak adhesion.

1. Surface Preparation

Before installing expanded metal lath, ensure the surface is clean, dry, and free of dust, debris, or loose particles. Proper preparation creates a stable base, improving adhesion and overall performance.

2. Fastening

Use staples, lath screws, or nails that are appropriate for the substrate. Fasteners should penetrate deeply enough to secure the lath firmly and prevent movement during plaster or stucco application.

3. Overlap Sheets

When joining multiple sheets, overlap them by at least one inch. This practice ensures continuous coverage, eliminates weak points, and strengthens the overall structure of the wall or surface.

4. Alignment

Keep lath sheets flat and properly aligned to avoid warping or uneven surfaces. Correct alignment promotes uniform plaster application and enhances the strength of the final finish.

5. Corners and Edges

Reinforce corners and edges using extra lath or corner beads. This step prevents cracking, chipping, or wear over time, especially in high-stress areas of walls and ceilings.

6. Protective Measures

For exterior projects, apply a corrosion-resistant coating or primer before plastering. This added layer of protection helps extend the life of the lath against moisture and weather exposure.

7. Handling

Wear gloves and protective clothing when working with expanded metal lath. Since its edges are sharp, proper handling ensures safety and prevents accidental cuts or injuries.

Maintenance and Longevity

Maintaining structures that incorporate expanded metal lath is essential for extending durability and ensuring long-term structural performance. Proper upkeep helps minimize repair costs while preserving safety and appearance.

-

Regular Inspections

Carry out routine checks for rust, corrosion, or surface damage, particularly in exterior applications exposed to harsh weather. Early detection allows for corrective action before small issues escalate into structural concerns.

-

Protective Coatings

Applying coatings such as paint, primers, or sealants enhances resistance against moisture, UV rays, and chemical exposure. These protective layers provide an added barrier that prolongs the lifespan of the lath.

-

Prompt Repairs

Addressing minor damage immediately prevents further deterioration that could compromise integrity. Replacing or reinforcing small affected areas ensures the rest of the installation continues to perform effectively.

-

Cleaning Practices

Accumulated dust, debris, or residues can interfere with adhesion in plastering or coating applications. Regular cleaning maintains functionality and improves the overall appearance of surfaces supported by expanded lath.

-

Structural Reinforcement

In areas subject to heavy loads or stress, additional sheets or supports should be installed. Reinforcement strengthens weak points and ensures the lath maintains stability over many years of use.

Choosing the Right Expanded Metal Lath for Your Project

Selecting the right type of expanded lath is essential to achieving durability, efficiency, and cost-effectiveness. Different projects require different lath types, so evaluating your specific needs ensures the best outcome.

-

Project Type

The choice of lath depends on where it will be used. Interior walls, exterior walls, ceilings, or decorative features each have unique requirements. For example, ceilings may need lightweight lath, while exterior walls demand more durable, weather-resistant options.

-

Environmental Conditions

Humidity, rain exposure, and chemical environments should influence your decision. Galvanized or coated lath performs better in moisture-prone or outdoor settings, while standard lath may be suitable for dry indoor environments.

-

Load-Bearing Needs

If the lath is reinforcing concrete or heavy plaster, thicker and stronger options are necessary. Lighter lath types may suffice for non-load-bearing decorative elements or partitions.

-

Budget Considerations

Cost is another factor to weigh. While galvanized and specialty lath may have higher upfront costs, they often deliver long-term savings by reducing maintenance and extending lifespan.

-

Ease of Installation

For projects requiring faster completion, self-furring lath is a practical choice. It eliminates the need for additional furring channels, saving both time and labor.

-

Surface Requirements

The desired finish also matters. Flattened lath is ideal for smoother plaster or stucco finishes, while standard lath provides the grip needed for textured surfaces.

Safety Considerations of Expanded Metal Lath

This is highly useful, but mishandling can create safety risks:

- Sharp Edges: Wear protective gloves to avoid cuts and punctures.

- Dust and Particles: Use masks and safety goggles when cutting or handling to prevent inhalation and eye injuries.

- Proper Fastening: Ensure sheets are securely installed to avoid hazards during plastering or construction.

- Heavy Lifting: Large sheets can be difficult to carry; use lifting equipment or team assistance.

Conclusion

Expanded metal lath is a versatile and essential material in modern construction, offering strength, flexibility, and long-lasting performance. Its wide range of applications ranging from plaster and stucco bases to concrete reinforcement, fireproofing, acoustic control, and decorative elements—demonstrates its adaptability.

Understanding the different types of lath, their benefits, installation practices, and maintenance requirements is crucial for achieving optimal results. Choosing the right lath for your project ensures durability, efficiency, and a professional finish.

By integrating expanded metal lath thoughtfully into your construction projects, you not only enhance structural integrity but also improve the aesthetic and functional performance of walls, ceilings, and decorative surfaces.

Investing time in proper selection, installation, and care of expanded metal lath ensures that your construction or renovation project stands the test of time.

FAQs

1. What is the primary material used in expanded metal lath?

Metal lath is primarily made from galvanized steel, providing strength, durability, and resistance to corrosion.

2. Can expanded metal lath be used for both interior and exterior applications?

Yes, depending on the coating and type, it can be used in both settings. Galvanized or paper-backed lath is preferred for exterior use.

3. How does self-furring expanded metal lath differ from standard lath?

Self-furring lath has raised edges that create spacing between the lath and the substrate, improving plaster adhesion and reducing labor requirements.

4. Is expanded metal lath suitable for DIY projects?

While it can be used for DIY projects, proper knowledge and tools are essential for safe and effective installation.

5. How can I ensure the longevity of structures using expanded metal lath?

Regular inspections, protective coatings, prompt repairs, and proper handling during installation help maximize durability.