When it comes to precision machining, the Hardinge lathe stands out as one of the most respected names in the industry. Known for reliability, craftsmanship, and accuracy, Hardinge lathes have been trusted by machinists, engineers, and manufacturing facilities for more than a century. Whether you are a hobbyist exploring metalworking or a professional shop manager, understanding Hardinge’s role in lathe manufacturing can help you appreciate why these machines continue to hold such a strong reputation today.

In this article, we’ll explore what a Hardinge lathe is, its history, where it’s made, whether the company is still in business, and why machinists across the world continue to value these legendary machines.

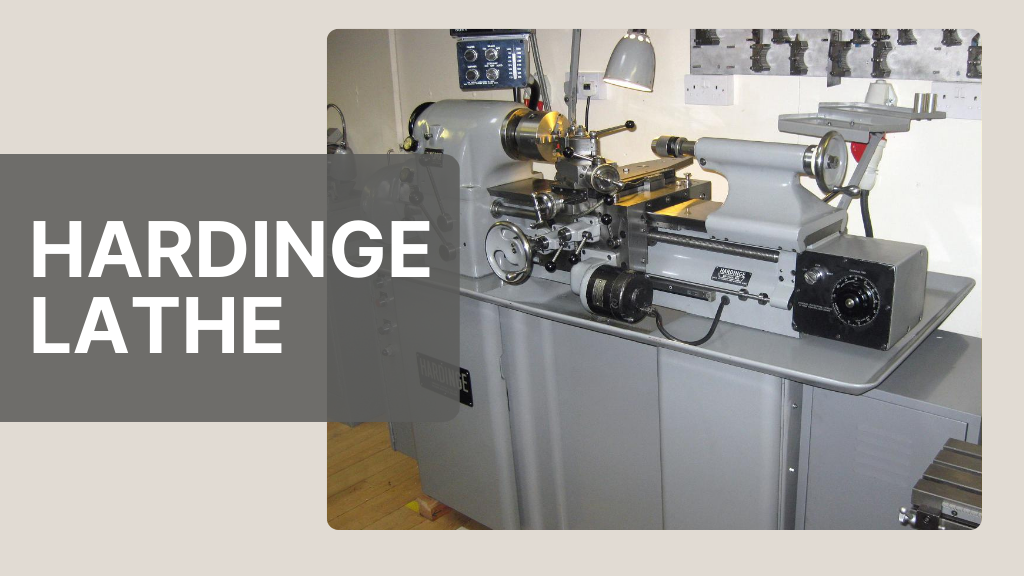

What is a Hardinge Lathe?

A Hardinge lathe is a precision-engineered machine tool designed for turning, threading, and machining metal components. Unlike generic lathes, Hardinge lathes are renowned for their tight tolerances, smooth operation, and longevity.

Key characteristics include:

- High precision: Capable of producing extremely accurate parts.

- Durability: Many decades-old models remain in use today.

- Versatility: Useful for toolrooms, production machining, and custom work.

- Craftsmanship: Built with premium materials and innovative design.

Hardinge lathes are especially known for their superior spindle accuracy and quality headstocks, which allow machinists to produce components with minimal runout. The most famous of these is the Hardinge HLV-H precision toolroom lathe, considered by many as the gold standard in small- to medium-sized metalworking.History of Hardinge Lathes

The Hardinge brand dates back to the late 19th century. Originally founded in Chicago, Illinois, the company quickly gained recognition for its innovative designs and reliable machine tools. By the early 1900s, Hardinge had established itself as a leader in collet systems and precision lathes.

Key Milestones in Hardinge’s History:

- 1890s: Hardinge Brothers Company established in Chicago.

- Early 1900s: Expansion into precision collet systems and toolroom lathes.

- 1930s–1940s: Introduction of world-class toolroom lathes, widely used in manufacturing and education.

- 1950s–1960s: Launch of the Hardinge HLV series, including the famous HLV-H lathe.

- Modern Era: Hardinge continues to produce manual and CNC (computer numerical control) lathes, expanding into milling machines and grinders.

This long history shows that Hardinge has consistently adapted to new technologies while maintaining its commitment to precision.

Where Are Hardinge Lathe Made?

A common question machinists and buyers ask is: “Where are Hardinge lathes made?”

For decades, Hardinge has been closely tied to American manufacturing. The company’s historic facility in Elmira, New York has long served as the hub for design, engineering, and production of its legendary precision lathes.

In recent years, Hardinge has expanded globally to remain competitive in the modern machine tool market. Today, the company operates with:

- North American headquarters in Elmira, NY: still an important center for production and innovation.

- International manufacturing facilities in China, Taiwan, and Switzerland: helping Hardinge serve customers worldwide with a broad product range.

Even with this global footprint, machinists continue to prize U.S.-made Hardinge lathes for their exceptional craftsmanship, durability, and long-term reliability. Many buyers specifically seek out older “Made in USA Hardinge lathes” because of their legendary build quality and proven performance in toolrooms and production floors.

Is Hardinge Still in Business?

Yes, Hardinge is still very much in business and continues to play a leading role in the global machining industry. Over the decades, the company has maintained its reputation for precision, reliability, and consistent innovation. Machinists and manufacturers worldwide trust Hardinge for both new machines and long-term service. Its legacy of high-quality engineering makes it a benchmark in the machine tool sector.

-

Manual Lathes

Hardinge continues to produce manual lathes, including the legendary HLV-H, which remains a cornerstone of precision toolrooms. These lathes are renowned for their unmatched accuracy and smooth operation. Many machinists still rely on Hardinge manual lathes for training, prototyping, and fine detail work. Their long-lasting construction ensures decades of dependable use in demanding workshops.

-

CNC Lathes and Turning Centers

In addition to manual lathes, Hardinge offers CNC lathes and advanced turning centers designed for automated, high-volume production. These machines combine the company’s heritage of precision with modern technology to improve speed and efficiency. Manufacturers can achieve faster output without compromising accuracy or quality. This makes Hardinge CNC systems a preferred choice for complex industrial applications.

-

Milling Machines, Grinders, and Collet Systems

Hardinge has expanded beyond lathes, producing milling machines, grinders, and collet systems to provide complete machining solutions. These products serve both small shops and large industrial facilities with versatility and precision. Machinists benefit from integrated systems that handle a wide range of applications. Hardinge’s expansion demonstrates the company’s commitment to innovation and customer needs.

-

Global Operations and Support

Today, Hardinge operates as a global machine tool manufacturer, serving industries such as aerospace, automotive, defense, and medical devices. The company also provides parts, servicing, and ongoing support for older machines, ensuring that decades-old Hardinge lathes remain operational. This continued support reinforces customer trust and preserves the value of past investments. Hardinge’s global presence guarantees that machinists worldwide can access reliable machines and expert service.

Why Are Hardinge Lathes So Popular?

Machinists consistently recommend Hardinge lathes for several key reasons:

-

Unmatched Precision

Hardinge lathes are celebrated worldwide because of their unmatched precision. These machines are designed to achieve accuracy down to tenths of a thousandth of an inch, making them indispensable for toolrooms and high-tolerance work.

-

Longevity

Their longevity is another reason machinists love them. Many lathes built in the 1950s through the 1970s are still running daily, proving Hardinge’s reputation for durability and long-lasting craftsmanship.

-

Smooth Operation

The operation of a Hardinge lathe is smooth and reliable. Thanks to finely engineered headstocks, bearings, and spindles, these machines run with minimal vibration, ensuring consistent results in every cut.

-

Toolroom Standard

Hardinge has also become the global toolroom standard. For decades, engineering schools, government labs, and industrial toolrooms have chosen Hardinge for training, precision machining, and research work.

-

Support and Parts Availability

Finally, the company provides excellent support and parts availability. Unlike many competitors, Hardinge continues to support older models, enabling machinists to restore and maintain their lathes for future generations.

Famous Hardinge Models

Hardinge has produced many legendary machines over the years, and some models have become true icons in the machining industry. These machines are celebrated for their accuracy, durability, and performance. From manual lathes to advanced CNC systems, each model highlights Hardinge’s commitment to precision and long-lasting quality.

-

Hardinge HLV-H Toolroom Lathe

The Hardinge HLV-H is often considered the best manual precision lathe ever built. It is praised for its unmatched accuracy, smooth operation, and exceptional reliability. Over the years, this model has earned a reputation for lasting decades without losing performance. Because of these qualities, machinists worldwide continue to rely on it whenever extreme precision is required.

-

Hardinge DV-59

The Hardinge DV-59 is a turret lathe designed for production runs and repetitive machining tasks. Known for its efficiency and versatility, it became a favorite in workshops that required consistent output. Its adaptability made it useful across a wide range of industries, and even today, many machinists continue to use the DV-59 for high-quality production work.

-

Hardinge DSM-59

The Hardinge DSM-59 was engineered for speed and high-volume output, making it ideal for small-part manufacturing. It quickly became popular in industries that required precision components, such as aerospace and medical device production. This model is still remembered as one of the most reliable lathes for repetitive, detail-oriented work.

-

Hardinge CNC Turning Centers

In more recent years, Hardinge has focused on developing advanced CNC turning centers to meet modern industrial needs. These machines combine automation with the company’s long-standing reputation for precision and durability. By producing complex parts at scale while maintaining accuracy, Hardinge has proven its ability to adapt to changing technology and remain a leader in machining solutions.

Modern Applications of Hardinge Lathe

Today, Hardinge lathes are used across multiple industries:

1. Aerospace

In the aerospace industry, Hardinge lathes play a vital role in producing high-precision components. They are used to machine engine parts, turbine blades, and structural elements where accuracy is critical. The tight tolerances of Hardinge equipment ensure safety and performance in flight operations.

2. Medical Devices

Hardinge lathes are trusted for crafting surgical instruments and medical implants. The medical field requires exceptional precision and consistency, which these machines deliver. Their ability to handle complex shapes makes them ideal for producing life-saving devices.

3. Defense

In defense manufacturing, Hardinge machines are used for weapons, vehicle components, and advanced military systems. Precision machining ensures durability and reliability under extreme conditions. This makes Hardinge a preferred choice for defense contractors.

4. Automotive

The automotive sector relies on Hardinge lathes for gears, shafts, and high-performance prototypes. Their precision helps manufacturers achieve efficiency in mass production while maintaining quality. This supports both innovation and large-scale vehicle manufacturing.

5. Education & Research

Universities and technical institutes continue to use Hardinge lathes for teaching and training. They allow students to learn advanced machining techniques on professional-grade equipment. This ensures the next generation of machinists enters the workforce with strong practical skills.

Hardinge vs. Other Lathes

When compared with other brands, Hardinge stands out because of its ability to maintain exceptionally tight tolerances. These machines achieve a level of accuracy that few competitors can consistently match. For machinists working on projects where precision is non-negotiable, this makes Hardinge a top choice. It ensures reliability across a wide range of industrial applications.

-

Hardinge Durability and Longevity

Another area where Hardinge earns recognition is longevity. Many users report their machines lasting decades, often passed down across generations of workshops. This level of durability reduces the need for frequent replacements or major repairs. As a result, the lifetime value of a Hardinge machine is considered extremely high.

-

Hardinge Pricing and Value

It’s true that Hardinge machines come at a premium price point compared to other brands. However, the cost is justified by the unmatched precision, reliability, and extended service life. For businesses that depend on consistent machining results, this investment pays off. The combination of quality and performance outweighs the higher upfront expense.

-

Hardinge vs. Competitors

While brands like South Bend, Monarch, and Clausing each have their own dedicated user base, Hardinge remains a benchmark in precision machining. Its reputation is built not only on performance but also on consistent innovation. Machinists often compare competitors to Hardinge as the industry standard. This status reinforces its position as a leader in the market.

Real-World Example: A Shop Using Hardinge

A small aerospace subcontractor in California reported that its HLV-H lathes from the 1960s were still producing precise, high-quality parts for aircraft engines. Rather than replacing them with cheaper imported machines, the company opted to rebuild and service its Hardinge lathes. This approach allowed them to maintain top-level performance while preserving their investment. It demonstrates that Hardinge machines can remain competitive and reliable for decades in demanding industries.

Conclusion

The Hardinge lathe is more than just a machine tool, it is a symbol of craftsmanship, accuracy, and durability. For over 100 years, Hardinge has built a reputation that makes its lathes some of the most sought-after machines in workshops across the globe. Whether you’re running a modern CNC operation or managing a traditional toolroom, Hardinge continues to deliver machines that stand the test of time.

If you’re considering investing in a lathe, Hardinge remains a top choice for machinists who demand precision, reliability, and long-term value.

FAQs

What is a Hardinge lathe?

The Hardinge lathe delivers precision, accuracy, and reliable, long-lasting performance. Widely used in toolrooms and manufacturing facilities, it delivers consistent, high-quality results for a variety of machining applications.

Where are Hardinge lathes made?

Hardinge primarily manufactures its lathes in Elmira, New York, USA, with additional production facilities in Asia and Europe.

Is Hardinge still in business?

Yes, Hardinge continues to manufacture manual and CNC lathes, milling machines, grinders, and collet systems worldwide.

Why are Hardinge lathes so expensive?

They meet the highest standards, delivering unmatched precision and lasting durability. Many machinists consider them a long-term investment.

Can you still buy parts for older Hardinge lathes?

Yes, Hardinge provides parts, manuals, and servicing for older models, making it easy to maintain decades-old machines.