Learn how to level a lathe machine like a pro with our comprehensive step-by-step guide to precision alignment. Achieve accurate machining results effortlessly.

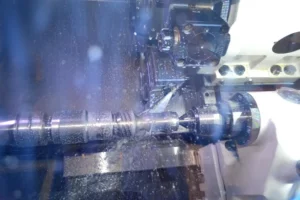

Leveling the machine is a crucial step in ensuring its optimal performance. Whether you’re working with a standard lathe, a CNC lathe, a bench lathe, or a mini lathe, proper leveling and alignment are essential for precision machining. In this comprehensive guide, we’ll walk you through the steps on how to level various types of lathes, align the tailstock and headstock, and perform essential lathe tests.

How to Level a Lathe Machine

Leveling a lathe machine is the foundation of achieving accurate machining results. Follow these steps to ensure your lathe is properly leveled:

- Prepare a Stable Surface: Start by placing the lathe on a flat and steady surface. This ensures that the lathe won’t wobble during operation.

- Use Gage Blocks: Employ precision gage blocks to hold a leveler above the lathe’s V-ways. This allows you to check the lathe’s level accurately.

- Back and Forth Procedure: Leveling is an iterative process. Make minor adjustments to the lathe’s feet or leveling screws and wait for the bubble in the level to settle.

- Calibration Check: Properly calibrate the level to ensure it reads the same at any angle.

- Consistent Position: Stand in the exact location for each measurement to maintain consistency.

Align the Tailstock and Headstock

Aligning the tailstock and headstock is crucial for achieving precise turning operations. Follow these steps for proper alignment:

- Use a Test Bar: Insert a test bar between the lathe’s spindle and tailstock centre. Make sure it is aligned with the tailstock centre.

- DTI Measurement: Place a Dial Test Indicator (DTI) at the edge of the test bar and measure the alignment. The appropriate alignment should be within 0.01 inches per 100mm.

How to Test a Lathe?

To ensure that your lathe is in optimal condition, perform the following examinations:

- Leveling: As discussed earlier, ensure that the lathe is correctly leveled. This helps prevent vibration and ensures accurate machining results. Using a precision level, adjust the feet or add shims as needed to achieve proper balance and stability during operation.

- Location Cylinder: Check if the location cylinder runs true on the main spindle. This ensures proper alignment and minimizes the risk of errors during machining. If any wobble or deviation is observed, inspect the spindle and mounting surfaces for wear or debris.

- Axial Slip: Inspect for any axial slip off the main spindle. Axial movement can affect machining precision and lead to uneven cuts. If a slip is detected, check the spindle bearings and locking mechanisms for wear or improper adjustment.

- Shoulder Face: Ensure that there is true running off the shoulder face of the spindle nose. This is essential for maintaining consistent part alignment and surface finish. Use a dial indicator to check for runout and correct any discrepancies before proceeding.

- Headstock Center: Confirm that the headstock centre runs true. Accurate alignment ensures that the workpiece rotates precisely around its axis. If any deviation is found, realign or adjust the headstock to maintain machining accuracy.

- Saddle Movement: Check that the central spindle operates parallel to the saddle movement. This alignment is crucial for achieving straight cuts along the workpiece. Any misalignment should be corrected by adjusting the saddle guides or verifying the bed’s accuracy.

Do Lathes Need to Be Level?

In precision machining, lathes must be level for accurate results. Levelness ensures proper alignment, preventing deviations in the workpiece and preserving tool precision. A meticulous process involving foundation inspection, precision level utilization, and regular maintenance is crucial for sustained optimal performance.

How to Level a Benchtop Lathe

To level a benchtop lathe, consider using the two-collar method:

- Chuck a sturdy bar with a minimum diameter of 1 inch.

- Perform a cross-feed lock.

- Check for an undercut section between the two collars, forming a dumbbell shape.

- If the lathe is aligned correctly, the two collars will have identical diameters.

How to Level a CNC Lathe

For CNC lathes, follow these steps to ensure proper leveling and alignment:

- Level a lathe machine using the four outer pads.

- Verify that the machine cuts parallel by running a cut on a scrap piece.

- A diameter deviation of 0.0005 inches indicates a balanced machine. If not, square the head for alignment.

How to Install a Mini Wood Lathe?

When installing a mini wood lathe, consider these steps:

-

Mount the lathe firmly in a fixed location to ensure stability and safe operation.

-

Secure the lathe’s legs firmly to the workbench or the floor to ensure stability during operation.

-

Assemble the headstock and tailstock on the stand securely.

-

Check for loose screws and tighten them.

-

Measure the centres to verify alignment.

-

Ensure the lathe bed is even and lubricated for smooth operation.

-

Set the tool rest at a 90-degree angle.

- Mount the wood blank onto the lathe for turning.

Conclusion

The proper level of a lathe machine and alignment are essential for achieving precision in lathe machining, regardless of the type of lathe you’re using. Following the provided steps ensures that your lathe operates at its best, minimizing errors and enhancing the quality of your work. Regular maintenance checks are crucial for consistent performance. Whether you’re a hobbyist or a professional, precision in lathe setup is key to success in machining.

FAQs

Do lathes need to be level?

Yes, lathes need to be level to ensure accurate machining and prevent errors in the workpiece.

How often should I check the alignment of my lathe?

It’s a good practice to check the alignment of your lathe regularly, especially after moving or transporting it.

What is the significance of aligning the tailstock and headstock?

Aligning the tailstock and headstock ensures that the lathes’ centres are in perfect alignment, allowing for precise turning operations.

Can I level a lathe on my own, or should I seek professional assistance?

You can level a lathe on your own by following the provided guidelines. Still, if you’re unsure or need to align a complex CNC lathe, it’s advisable to seek professional assistance.