The lathe bed is one of the most critical components of a lathe machine. It serves as the foundation that supports the headstock, tailstock, and carriage while maintaining the machine’s alignment and stability. A well-designed and maintained bed ensures smooth operation, reduces vibrations, and guarantees precision in turning, facing, tapering, and other machining operations. For machinists, engineers, and hobbyists alike, understanding its design, function, and maintenance requirements is crucial for achieving high-quality results.

In this comprehensive guide, we will explore its design, the types of loads it bears, how to check it, the working principle of taper turning attachments, maintenance tips, and common challenges. We will also answer frequently asked questions to give you a complete understanding of this essential component.

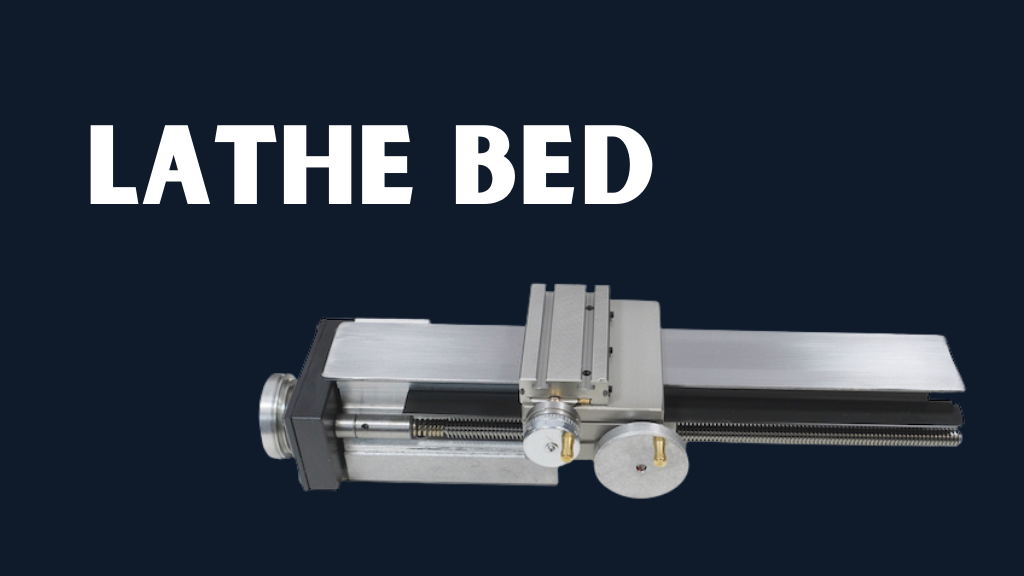

What is the Bed of a Lathe?

The main structure of a lathe machine serves as the foundation that holds all other components in precise alignment. It ensures that the cutting tool moves smoothly along the workpiece without deviations. This frame is engineered to be rigid enough to withstand cutting forces while remaining resistant to vibrations and thermal expansion.

Key Features

Understanding the key features of a lathe helps in selecting the right machine and maintaining it effectively. Most beds are made from cast iron because of its excellent vibration-damping properties and durability. Steel and composite beds are used in specialized applications for higher strength or thermal stability. Precision-machined guideways allow the carriage and tailstock to move smoothly along the bed. The quality of these guideways directly influences machining accuracy and surface finish.

The length and width of the bed determine the maximum size of workpieces it can accommodate. Longer beds are suitable for larger components, while wider beds provide greater stability for heavy workpieces. A smooth surface finish minimizes friction and wear, extending the lifespan of both the bed and other components. Properly finished beds also enhance cutting accuracy and consistency. Overall, these features ensure efficient, precise, and reliable operation.

Types of Lathe Bed

It can be categorized based on their design and application. Understanding these differences helps in selecting the right lathe for precise machining tasks. The choice of bed impacts stability, alignment, and overall performance. Each type offers unique advantages suited to specific operations. Proper selection ensures long-term reliability and accuracy.

Flat Bed

Flat beds have horizontal guideways and are simpler to manufacture. They are widely used in general-purpose lathes for standard machining tasks. While slightly less precise than other types, they provide cost-effective and reliable performance. Their straightforward design makes maintenance easier. Flat beds are ideal for workshops with diverse applications.

V-Shaped Bed

V-shaped beds feature guideways in a V form, which promotes self-alignment of the carriage. This design reduces lateral movement and ensures higher machining precision. Precision lathes often use V-shaped beds for complex or high-accuracy operations. They maintain stability during extended or heavy-duty tasks. Properly maintained, they enhance the lifespan of the lathe.

Combination Bed

Combination beds incorporate both flat and V-shaped guideways, merging the benefits of each type. They provide high alignment precision along with overall stability for varied machining operations. These beds are common in high-end industrial lathes that require versatile performance. They offer consistent results for both heavy and delicate components. Regular maintenance ensures their long-term reliability.

Inclined Bed

Inclined beds are slightly angled, allowing chips and debris to fall away from the workpiece. This feature helps maintain cutting accuracy during prolonged operations. They are typically used in heavy-duty lathes to reduce contamination and wear. Inclined beds improve efficiency in continuous production environments. Proper cleaning and leveling enhance their durability and performance.

How to Check a Lathe

Regular inspection is essential to maintain machining accuracy and extend the life of the machine. By routinely checking the frame and guideways, operators can prevent misalignment, reduce wear, and avoid costly repairs. Start with a visual inspection to identify scratches, dents, or signs of corrosion, as even minor imperfections can affect precision. Metal chips, coolant residues, or rust buildup can interfere with smooth movement along the guideways. Maintaining clean and well-inspected surfaces ensures consistent and safe operation.

Next, verify the straightness of the guideways using a precision straight edge and check the alignment of the carriage and tailstock. Ensure the frame is level with a spirit level to prevent uneven wear and reduced accuracy. Measure wear along the guideways using a dial indicator to detect material loss or deformation. Professional scraping or re-machining may be needed if excessive wear is found. Following these steps helps maintain optimal machine condition, ensuring precise and high-quality machining results.

What Type of Load Does the Lathe Structure Handle?

The lathe structure must handle several types of loads during operation. Understanding these loads is crucial for selecting the right machine and ensuring safe, precise machining. Properly designed beds help maintain accuracy and durability. Each load type can affect performance differently. Awareness of these forces allows operators to take preventive measures.

Static Load

Static load refers to the weight of the headstock, tailstock, carriage, and workpiece resting on the lathe. The structure must support this weight without bending or deflecting. A rigid design prevents misalignment and maintains consistent cutting accuracy. Ensuring the bed can handle static loads increases the machine’s lifespan. Proper foundation and installation help manage this load effectively.

Dynamic Load

Dynamic load occurs during cutting operations when the tool exerts force on the workpiece. This generates vibrations that can reduce precision and surface finish. High-quality materials, such as cast iron, are used to absorb these vibrations. Minimizing dynamic effects ensures smoother operation. Proper lubrication and maintenance further help control this load.

Impact Load

Impact load happens when the cutting tool engages suddenly or encounters accidental contact. The lathe structure must withstand shocks without permanent deformation. Durable materials and reinforced designs are essential to handle such forces. Preventing excessive impact prolongs the life of both the bed and other components. Operator care also plays a key role in reducing impact risks.

Thermal Load

Thermal load results from heat generated during machining due to friction between the tool and workpiece. This heat can cause slight expansion and distort the structure, affecting accuracy. Some precision lathes use special materials to minimize thermal effects. Proper cooling, lubrication, and controlled cutting speeds help reduce thermal stress. Managing thermal load ensures consistent performance over long operations.

Taper Turning Attachment: Working Principle

A taper turning attachment allows a lathe to cut precise tapered shapes. It is widely used in automotive, aerospace, and tooling applications.

Working Principle

A taper turning attachment connects to the carriage or cross-slide of the lathe, allowing precise control over the cutting tool’s movement. Once installed, it guides the cutting tool along a predetermined angle relative to the bed of the lathe. As the tool progresses, it gradually moves along the length of the workpiece, producing a uniform taper with consistent dimensions. This attachment ensures accuracy and repeatability, making it essential for applications that require precise tapered components.

Advantages

Taper turning attachments are designed to produce highly accurate tapered components, ensuring consistent dimensions along the workpiece. By guiding the cutting tool precisely, they significantly reduce manual errors and improve overall machining consistency. These attachments are versatile and can be used with a variety of lathe machines, making them suitable for different workshop setups. Because of their ability to deliver precision and repeatability, taper turning attachments are indispensable in industries such as automotive, aerospace, and tool manufacturing, where exact tolerances are critical for performance and safety.

Real-World Applications

The lathe bed is a core element in industries like automotive, aerospace, tool and die making, and custom machining. In automotive production, it ensures accurate shaping of crankshafts, camshafts, and axles where even minor errors can affect performance. Aerospace work requires higher precision, often relying on heavy-duty beds and taper attachments to handle tough alloys safely and consistently. Tool and die manufacturers also depend on reliable alignment for creating molds, dies, and jigs needed in mass production.

Smaller workshops and hobbyists benefit from the same stability on a reduced scale. A well-maintained bed allows consistent results when crafting prototypes, replacement parts, or detailed models. Routine care such as cleaning, lubrication, and proper leveling helps extend machine life while preserving accuracy.

Maintenance Tips

The structure of a lathe is designed to handle different types of loads that occur during operation. Static loads come from the weight of the headstock, tailstock, carriage, and workpiece, which the frame must support without bending. Dynamic loads are generated during cutting, as the tool applies pressure on the material, causing vibrations that may affect accuracy. A well-designed structure helps reduce these vibrations and maintain smooth performance.

Impact and thermal loads also play a role in lathe operation. Impact loads occur when the tool suddenly engages the workpiece or accidental contact happens, requiring the machine to resist shocks without damage. Thermal loads arise from the heat generated by friction, which may cause slight expansion and affect precision. Advanced machines often use materials that minimize these distortions to ensure long-term reliability.

How to Choose the Right Bed

Selecting the right lathe bed plays a major role in ensuring accuracy, stability, and durability. The choice often depends on the type of machining work, the size of the workpiece, and the bed material. For high-precision work such as aerospace or tool manufacturing, V-shaped or combination beds are preferred. These designs provide better alignment, reduce vibrations, and minimize errors during operation. Flat beds, on the other hand, are versatile and easier to maintain for general workshop use.

Material quality and overall construction are equally important when making a selection. Cast iron beds are popular because of their natural vibration-damping properties and long service life. Steel and composite beds are stronger options suited for heavy-duty or specialized applications. The length of the bed should match the size of the workpiece for smooth machining. Finally, a design that allows easy maintenance, lubrication, and inspection helps extend the lathe’s working life.

Common Challenges and Solutions

Even the most well-built lathe can face operational issues over time, affecting precision and efficiency. Guideways may wear unevenly due to the constant load from the carriage, tailstock, and workpiece. Corrosion can develop if moisture, coolant, or metal chips are left on the surface, leading to rust and reduced accuracy. Misalignment may occur from heavy loads or improper leveling, causing uneven cuts or tapering errors. Regular inspections, cleaning, oiling, and leveling help maintain smooth operation.

Vibration is another common challenge, especially on unstable foundations or during high-speed machining. Excessive vibration affects surface finish and accelerates wear on tools and guideways. Placing the lathe on a solid, level base and using vibration-damping materials can reduce oscillations. Ensuring all bolts are tight and components are secure enhances overall stability. Addressing wear, corrosion, misalignment, and vibration extends the machine’s service life and ensures consistent results.

Conclusion

The lathe bed is a vital component that ensures stability, precision, and efficiency in machining operations. By understanding its types, load-bearing capacity, maintenance needs, and accessories such as taper turning attachments, machinists can maximize accuracy and prolong the life of their lathes. Regular inspection, proper lubrication, and careful handling are essential for optimal performance.

FAQs

How often should a lathe bed be inspected?

Inspection every 6 to 12 months is recommended, depending on usage and workload.

Can worn guideways be repaired?

Yes, they can be professionally scraped or re-ground to restore accuracy.

What is the difference between flat and V-shaped guideways?

Flat guideways are simple to manufacture but offer less precision. V-shaped guideways provide better alignment and reduce lateral movement.

How does the bed material affect performance?

Cast iron absorbs vibrations effectively, improving precision. Steel is stronger but may transmit vibrations more easily.

Are taper turning attachments compatible with all lathes?

Most standard lathes support taper turning attachments, but compatibility should be verified with the manufacturer.