A self-ejecting lathe chuck key is a small tool with an outsized role in machining. Whether in a professional manufacturing plant or a home garage workshop, this tool ensures that the workpiece is clamped tightly and securely inside the chuck. It may appear simple, yet the way it is chosen, handled, and stored directly affects safety, accuracy, and the overall lifespan of both the chuck and the machine.

Many accidents in machine shops can be traced back to one mistake: leaving the key inside the chuck when starting the spindle. The force of a key being thrown outward can cause serious damage or severe injury. Because of this danger, machinists are trained early to respect the chuck key and remove it immediately after use. To reduce the risk of human error, many schools and industrial facilities now prefer self-ejecting keys that automatically release once pressure is removed.

This comprehensive guide explores everything you need to know about chuck keys, including the different types, safe usage practices, selection tips, maintenance routines, and replacement advice. It also provides real-world shop examples and frequently asked questions to help machinists make informed decisions and work with greater confidence.

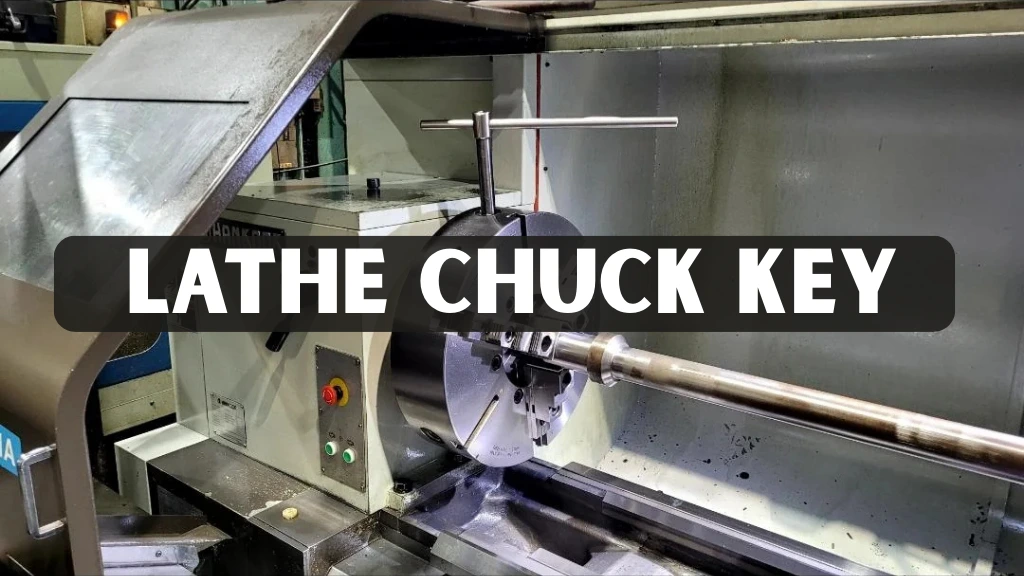

What is a lathe chuck key

A chuck key is a specialized wrench used to tighten or loosen the jaws of a chuck. The chuck holds the workpiece, and the key provides the leverage required to clamp it firmly in place. While some chucks use hand-tightening mechanisms, many lathes and drill presses rely on keyed systems because they deliver stronger clamping force. Without the key, it would be nearly impossible to achieve the level of grip needed for precise machining.

In practice, machinists use the key repeatedly during the day. Each time a part is changed, the chuck is loosened and retightened. This repetition makes the tool indispensable, but it also means that even experienced operators must stay mindful of safety.

Why chuck keys matter in machining

Chuck keys are more than just accessories, they are fundamental to the performance and safety of the machine. A properly tightened lathe chuck key guarantees that the workpiece remains centered and secure throughout the process. This stability minimizes run-out and ensures accuracy in machining operations. Even a small slip during rotation can compromise the part, damage the cutting tool, and waste valuable material.

Safety is another reason the chuck key plays such an important role in every workshop. Leaving a key in the chuck is one of the most common hazards in machining, and unfortunately it is a mistake even experienced operators can make. When the spindle is powered on, the spinning motion transforms the key into a dangerous projectile. Training programs across the industry consistently emphasize that machinists must never step away from a machine without removing the key first.

Efficiency is the third factor that highlights why this simple tool matters. A well-designed key allows comfortable operation and speeds up the process of loosening and tightening parts. Over the course of a single workday, this convenience adds up to real time savings, particularly in fast-paced environments. In production settings where deadlines are strict and precision is non-negotiable, the ability to work efficiently with the right key makes a measurable difference.

Chuck Key Types and Variations

There are several types of chuck keys available, and each one is suited to different machining needs. The most familiar design is the standard T-handle, which uses either a square or hexagonal drive tip. Its simple yet effective shape provides excellent leverage, making it a versatile option for most small and medium-sized machines used in workshops.

Self-ejecting keys represent a safer alternative and are especially valued in training centers or high-volume shops. These keys include a spring-loaded mechanism that automatically pushes the tool out of the chuck once released. Because of this feature, they greatly reduce the risk of a machinist accidentally leaving the key in place. Their design makes them one of the most reliable options for safety-focused environments.

Shorter L-handle keys are another variation, designed for situations where space is limited or where large T-handles cannot be used. Although they do not provide the same level of torque, a lathe chuck key of this style is practical for smaller machines and lighter applications. Four-way or combination keys are also available, offering multiple key sizes on a single tool, which can be convenient in shops handling different equipment types.

Finally, certain chucks are manufactured with hexagonal drive sockets rather than square ones, and these require hex-style keys. These often feature coated or textured handles to improve grip and comfort during frequent use. While less common than the traditional T-handle, hex keys are reliable and widely used in shops where specialized chucks are part of daily operations.

How to use a chuck key safely

Safe use of a chuck key follows a simple but important routine. First, the machinist selects the correct size lathe chuck key that matches the chuck’s drive hole. Using a mismatched key can wear out both the key and the chuck over time. Once the correct tool is chosen, it is inserted into the chuck and turned counterclockwise to loosen the jaws. The workpiece is then placed inside, centered as carefully as possible, and the jaws are snugged down by hand.

After the workpiece is positioned, the machinist uses the key again, turning clockwise to tighten firmly. For larger chucks, it is often recommended to tighten from two opposing holes to achieve even pressure. Once tightening is complete, the key must be removed immediately. This step cannot be stressed enough, as leaving the key in the chuck is the most common cause of accidents related to this tool. Many machinists adopt the habit of placing the key in the same designated spot every time, which helps reinforce muscle memory.

Sizes and compatibility

Chuck keys are manufactured in a variety of sizes to match the drive sockets on different chucks. The most common are square drives, which usually range between 1/4 inch and 1/2 inch. Larger industrial machines, however, may require sizes up to 3/4 inch to handle the added strength and torque needed for heavy-duty work. In some setups, hex drives are used instead, typically available in 13 millimeters, 16 millimeters, or 19 millimeters.

To determine the correct size, machinists often measure the chuck’s keyhole directly or consult the manufacturer’s specifications. This ensures that the chosen tool is an exact fit for the chuck, providing both secure tightening and long-term reliability. Precision in this step is especially important in workshops where multiple machines with varying chuck sizes are in use.

Using the wrong size is one of the most frequent causes of chuck-related problems. A loose-fitting key may slip during tightening, while one that is too large won’t fit at all. Over time, mismatched tools can wear down the chuck’s internal mechanism, shortening its service life and increasing safety risks. Properly sizing the chuck key not only prevents damage but also ensures smooth and consistent operation.

Choosing the right chuck key

Selecting the right chuck key goes beyond simply matching the size. The handle length matters, as longer handles provide more torque for heavy-duty applications, while shorter handles are easier to maneuver in confined areas. The material is another consideration. Keys made from hardened steel last longer and resist wear, while softer materials may wear down quickly under heavy use.

Comfort features such as vinyl-coated handles, textured grips, or knurled surfaces can make frequent use less tiring, especially when working with oily or greasy hands. Safety features should also be considered. Self-ejecting designs are particularly beneficial in environments where multiple operators share machines, since they reduce the likelihood of accidents. For a busy production shop, investing in these safety upgrades can be more cost-effective in the long run than dealing with lost time or injuries.

Maintenance, storage, and prevention of loss

Because of their small size, chuck keys are easily misplaced. This often disrupts workflow, leading some operators to use unsafe substitutes such as pliers or screwdrivers. A better solution is to establish consistent storage habits. Many shops attach magnetic strips or racks near each machine, creating a permanent home for the key. Others tether keys to the machine with retractable reels or short cables, ensuring the tool never leaves its station.

Regular inspection of chuck keys is another part of good maintenance. If the corners of the drive begin to round off, or if the handle shows signs of bending, the key should be replaced before it damages the chuck. Some shops label their machines and keys, creating accountability and reducing the chances of tools wandering between stations. Combined with a culture of discipline, these practices prevent both accidents and unnecessary downtime.

Replacements and universal options

It is not uncommon for chuck keys to go missing, especially in shared environments. When replacement becomes necessary, the best approach is to purchase a key that exactly matches the chuck’s specifications. Universal or four-way keys can serve as temporary solutions, but they are not always precise fits. Over time, this mismatch can cause wear or slippage.

Improvised tools, such as pliers or screwdrivers, should never be used. They may seem like quick fixes but often result in damaged equipment and unsafe conditions. The cost of a proper replacement key is negligible compared to the potential harm caused by using the wrong tool.

Where to buy and what to expect

Chuck keys are widely available from industrial suppliers, hardware stores, and online retailers. Standard models are inexpensive, typically costing only a few dollars, while hardened steel or self-ejecting designs may be priced higher. Customers often leave reviews that highlight durability and ease of use, with many branded suppliers maintaining ratings of 4.7 stars or more from hundreds of users.

An authoritative overview of chuck types and uses is available in Wikipedia’s chuck article. This resource explains not only the mechanics behind clamping systems but also the variations of chucks that require different keys, providing additional technical depth for readers who want to go beyond basic descriptions.

Practical shop examples

Real-world experiences illustrate the importance of the chuck key. At one technical training center, instructors equipped every student lathe with self-ejecting keys. Over the course of a semester, incidents of forgotten keys dropped to zero, and students reported that the automatic ejection encouraged better habits. In a small home workshop, a hobbyist replaced a generic key with a hardened steel model. The new tool fit more snugly, prevented slippage, and extended the service life of the chuck.

In a production facility with multiple machines, management solved the problem of misplaced keys by tethering each one to its respective lathe. This small change eliminated wasted time searching for tools and kept operations running smoothly. These examples demonstrate that even modest adjustments in tool selection and shop practice can significantly improve both safety and productivity.

Conclusion

A lathe chuck key may be a small object, but it plays an essential role in machining. It ensures that the workpiece is held securely, helps maintain accuracy, and prevents potentially dangerous accidents. By choosing the right type, handling it responsibly, and adopting safe storage habits, machinists can protect themselves and their equipment.

From hobbyists to industrial professionals, the message remains consistent: respect the chuck key, invest in a quality tool, and never underestimate its importance. The right practices around this simple device make a workshop safer, more efficient, and more professional.

FAQs

What happens if you leave a key in the chuck?

If the spindle is started with the key in place, it can be flung outward at high speed. This can result in serious injuries or machine damage.

Can I use pliers instead of a chuck key?

No. Substitutes like pliers or screwdrivers can damage the chuck and increase the chance of an accident.

How do I know what size key to buy?

Measure the chuck’s keyhole carefully or check the manufacturer’s manual. A proper fit ensures both safety and long-term performance.

Are self-ejecting keys worth it?

Yes, especially in shops with multiple operators or in training environments. They minimize the chances of leaving the key in the chuck.

How often should I replace a chuck key?

A chuck key should be replaced if it shows visible wear, rounding of the drive tip, or poor fit in the chuck. Regular inspection ensures safe operation and prevents unnecessary wear on the chuck itself.