The lathe compound slide is a compact yet powerful accessory that provides machinists with the ability to cut tapers, set precise angles, and control fine depths on a lathe. Its design allows for greater flexibility and accuracy compared to the standard cross slide, making it essential for detailed work. By mastering the compound slide, operators can achieve smoother finishes and more consistent results. This tool enhances both precision and efficiency in a wide range of machining tasks.

In this guide, you will learn how a compound slide works, its common applications, practical tips from experienced machinists, and key considerations when purchasing one. Each section is explained clearly so that the information can be applied directly to your projects. Understanding these concepts ensures safe, effective, and precise machining. Whether for hobby or professional use, the compound slide becomes an indispensable part of any lathe setup.

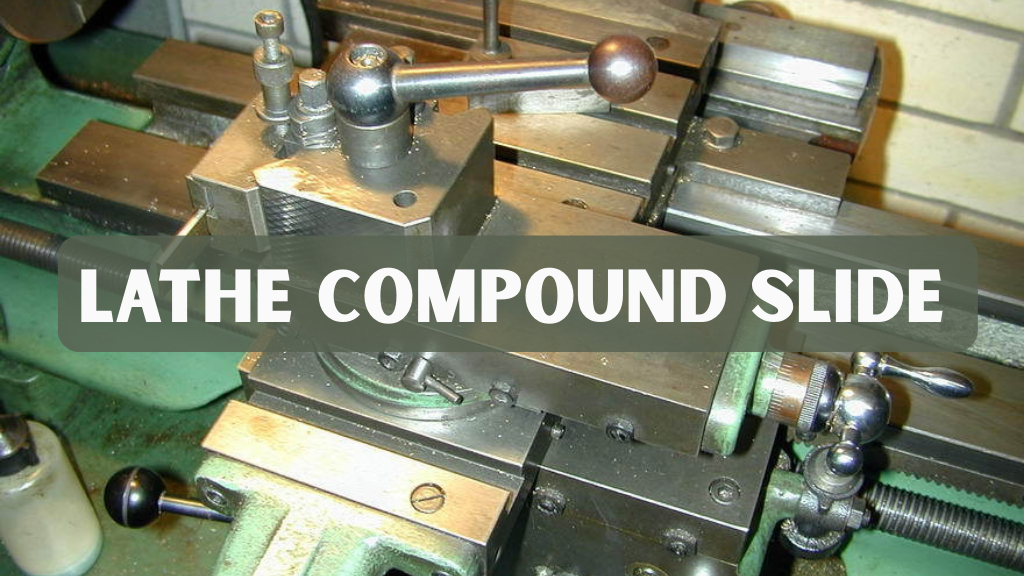

What is a Lathe Compound slide

A lathe compound slide, also known as a compound rest or top slide, is mounted on the cross slide and provides an additional axis of movement. It can be rotated and locked at specific angles, allowing machinists to set tapers, cut precise angles, and perform fine finishing passes. Unlike the cross slide, which handles larger radial adjustments, the compound slide offers shorter travel designed for precision work. This makes it ideal for tasks that require careful control and accuracy.

The compound slide is a vital tool in both hobbyist and professional machine shops due to its versatility. It is essential for cutting threads, finishing shafts, or producing angled surfaces with consistent quality. By offering precise control over small, detailed cuts, the compound slide enhances both efficiency and machining accuracy. Its use significantly improves the quality and consistency of precision projects across various applications.

Key Components and How it Works

The compound slide consists of multiple components that work together to provide precise and controlled motion. The base bolts securely to the cross slide and often features a graduated scale to indicate angles. This foundation ensures stability during machining operations. Proper alignment at the base is essential for achieving accurate results and smooth motion throughout the workpiece

The rotating head is a critical section that allows the machinist to set the slide to the desired angle. Once positioned, it can be locked securely to maintain consistency during cutting. The lead screw and handwheel provide small, precise linear movements, advancing or retracting the toolpost along the set angle. These components give the operator fine control for delicate machining tasks.

The toolholder mounts the cutting tool and sometimes accommodates quick-change toolposts for greater convenience. The compound slide is not intended for heavy stock removal but excels at precision tasks such as finishing cuts, threading, and short taper creation. By combining these features, the compound slide offers both versatility and reliability for detailed machining operations.

Common Uses of a Compound Slide

The lathe compound slide is especially valuable in operations that require both precision and flexibility. For taper turning, machinists can set the compound at an angle to take light, controlled cuts, producing short tapers with high accuracy. This method is often faster and more consistent than offsetting the tailstock. By providing precise control over the cutting angle, the compound slide enhances both efficiency and quality.

Angle cutting is another application where the compound slide proves indispensable. It allows operators to face or chamfer parts at exact angles without rotating the headstock. This precision reduces setup time and minimizes errors, making complex cuts more achievable. The ability to maintain consistent angles ensures better overall machining results and surface quality.

The compound slide is also ideal for fine finishing passes and hand threading operations. Its fine lead screw pitch allows delicate cuts that produce smooth surfaces and accurate dimensions. In manual threading, the slide controls cutting depth for precise results, though it requires careful setup and experience. These capabilities demonstrate the compound slide’s versatility and essential role in both professional and hobbyist machining environments.

Real World Examples

Sherline offers a compact compound slide that is widely used for benchtop lathes. It features angle markings, a locking ring, and handwheel graduations, allowing precise adjustments for fine work. Many hobby machinists favor this model for small projects, jewelry, and detailed machining tasks. Its compact design makes it ideal for limited workspace while maintaining accuracy. This combination of features makes it a reliable choice for precision applications.

Industrial suppliers like MSC Direct provide replacement compound slides for mini lathes and small industrial machines. These options are useful for upgrading or repairing existing setups to maintain efficiency and precision. Online communities and YouTube creators often demonstrate practical uses, such as taper cutting and threading. Channels like Blondihacks highlight real-world applications, showing the versatility and importance of compound slides in professional and hobbyist settings.

Buying Guide

When selecting a lathe compound slide, several factors influence precision and performance. Travel and lead screw pitch determine how finely the tool can be adjusted, with a smaller pitch providing more control. A clear angle scale and reliable locking mechanism ensure accuracy while saving setup time. Toolpost compatibility is essential to fit your existing setup or quick-change adapters. Considering these elements helps achieve consistent and precise machining results.

Construction quality and intended use are also crucial when choosing a compound slide. Smooth dovetail slides with adjustable gibs reduce play and improve surface finish. Matching the slide to your machine, whether a small jeweler’s lathe or a light industrial lathe, ensures proper functionality. Selecting the right compound slide enhances safety, efficiency, and long-term reliability. Investing in a suitable slide reflects both professional practice and machining expertise.

Setup and Basic Operation

Setting up a compound slide correctly is essential for achieving accurate machining results. Begin by securely mounting the compound to the cross slide, ensuring the base is aligned with the lathe centerline if necessary. Tighten all mounting bolts to prevent movement during operation. Proper alignment at this stage ensures precision in every cut and minimizes errors.

Next, rotate the compound to the desired angle using the graduated scale and lock the rotating base firmly in place. Install the cutting tool in the toolholder, making sure the tool height matches the workpiece centerline. This setup ensures that the tool engages the workpiece consistently and reduces the risk of uneven cuts. Accurate positioning is key for high-quality machining.

Finally, use the compound handwheel to perform small, controlled passes, relying on the cross slide or carriage for heavier cuts. Monitor the movement for excessive play or stiffness, and adjust the gib screws as needed. These adjustments maintain smooth operation and extend the life of the compound slide. Proper setup and careful handling guarantee precise, reliable results in all machining tasks.

Case study

A small workshop in Indiana that produces custom motorcycle parts struggled with creating short tapers on steel rods. The traditional tailstock offset method was slow and often produced inconsistent results. After upgrading to a high-quality compound slide with fine graduations, machinists reported faster setup times and more precise tapers. They set the compound to a 5-degree angle, locked it securely, and performed light handwheel passes. This improvement streamlined operations and reduced mistakes significantly.

The results included smoother finishes and less rework on every part. According to the shop owner, productivity increased by 20 percent on taper-related jobs. This case highlights the value of investing in accurate, well-built compound slides. Reliable equipment enhances machining precision, boosts operator confidence, and improves overall efficiency. Workshops can see measurable gains by adopting these modern machining practices.

Safety and Limitations

Compound slides are delicate compared to other lathe components and require careful handling. They are not intended for heavy stock removal, as aggressive use can lead to chatter, tool deflection, or damage. Always lock the compound when it is not in use to prevent accidental movement. Proper care and cautious operation help maintain accuracy and prolong the lifespan of the slide. Treating the compound slide with attention ensures consistent performance for precision tasks.

Maintaining dovetails and lead screws by keeping them clean and lubricated reduces wear and ensures smooth operation. Using sharp tools at appropriate speeds is critical for effective finishing cuts. Since the compound often handles light finishing, precision tooling is essential for a quality surface. Correct operation minimizes strain on the slide and prevents damage. Following these practices ensures long-term reliability and efficiency in machining.

Troubleshooting Common Issues

Excessive backlash in the compound slide is a common issue that affects machining accuracy. The solution often involves checking and adjusting the gib screws to restore proper movement. In cases where wear has damaged the lead screws, replacement may be required. Another frequent problem is when the slide feels tight or sticky during use, which interrupts smooth operation. Cleaning the dovetail surfaces, applying light oil, and loosening the gib slightly usually resolves this.

Inaccurate angle settings and chatter during finishing cuts are also challenges machinists encounter. Graduation markings and lock mechanisms should always be verified for alignment, while tools like protractors or dial indicators improve precision. Chatter can often be minimized by ensuring the cutting tool is sharp and the compound slide is locked when possible. Properly supporting the workpiece further reduces vibration and improves surface finish.

Advanced Tips for Machinists

Experienced machinists often maximize the versatility of the compound slide to achieve higher precision. By setting it parallel to the workpiece axis, they can dial in depths more accurately than the cross slide allows. This fine control ensures cleaner finishes and exact measurements. It reflects skill and confidence gained through years of hands-on practice.

The compound slide also proves valuable in specialized operations such as cutting shoulders and recesses. Its controlled feed allows machinists to work on smaller pieces with accuracy and stability. In some cases, long-travel compounds even serve as substitutes for taper attachments. This flexibility demonstrates the ingenuity of seasoned professionals in adapting tools to tasks.

Beyond these uses, the compound can assist in boring operations where angled positioning is required. Though less common, it provides machinists with an additional option when facing complex setups. The ability to creatively apply the compound showcases expertise and resourcefulness. This makes it an indispensable tool for precision machining and problem-solving.

Conclusion

The lathe compound slide is a small but highly versatile accessory that brings precision and control to lathe operations. It is especially valuable for taper turning, angle cutting, fine finishing, and threading tasks. By choosing a well built slide with smooth dovetails, reliable locks, and compatible toolpost fittings, machinists can expand the capability of their lathes significantly.

The case study shows how a simple upgrade improved productivity by 20 percent in a real motorcycle parts workshop. This demonstrates the impact that a high quality compound slide can have on efficiency and accuracy. Whether you are a hobby machinist or run a light industrial shop, understanding and using the compound slide effectively will improve both accuracy and efficiency. Keep it clean, well adjusted, and reserved for the right tasks, and it will serve you reliably for years.

FAQs

How does a compound slide differ from a cross slide

The cross slide provides larger radial movement and is used for general turning. The compound slide offers a short, rotatable axis for angle setting and fine adjustments.

Can I cut threads with a compound slide

Yes, single point threading can be done using the compound for controlled depth. This requires correct setup and is often used for precision threading on small parts.

What travel should I expect from a mini lathe slide

Mini lathe compounds usually have limited travel, often just a few millimeters. Check manufacturer specifications to confirm exact travel.

How do I reduce play in a compound slide

Adjust the gib screws as instructed by the manufacturer. Properly adjusted gibs reduce side play and backlash.

Is a compound slide necessary for beginners

While not strictly necessary, it greatly increases flexibility and precision. Many beginners benefit from having one even on entry level lathes.