Lathe machines play a crucial role across industries such as automotive, aerospace, and small-scale workshops, offering unmatched versatility in shaping and machining materials. However, their operation also comes with inherent risks that must be carefully managed to ensure workplace safety and compliance with standards. One essential solution is the lathe guards, a protective device designed to shield operators from potential hazards while keeping machines functional and efficient.

These safety components not only minimize the chances of accidents but also help organizations meet regulatory requirements and maintain smooth daily operations. In this article, we will explore their importance, different types, installation methods, compliance considerations, and maintenance strategies to show why they remain indispensable in modern machining environments.

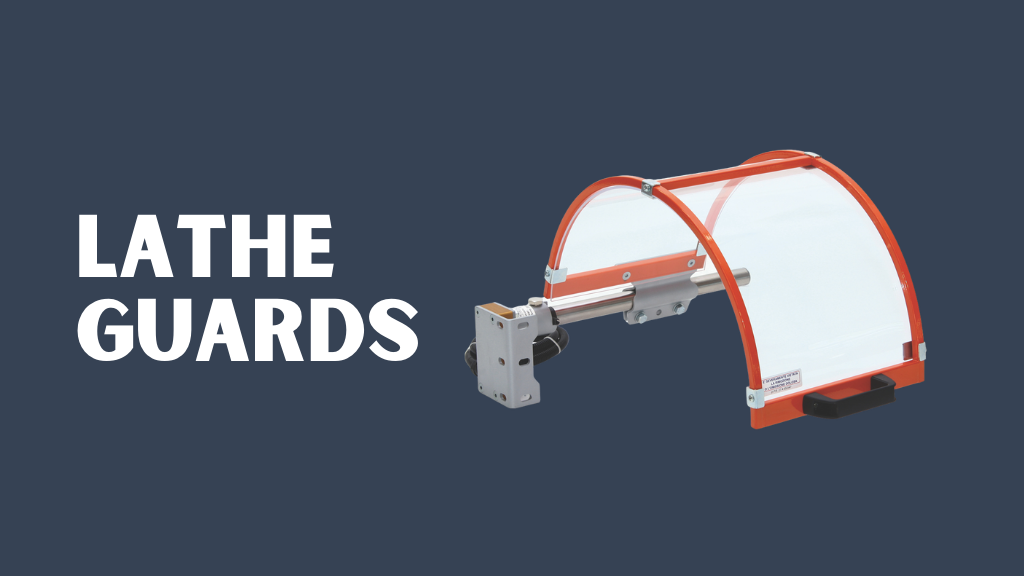

Importance of Lathe Guards

Lathe guards are essential safety components that serve as protective barriers between machine operators and hazardous moving parts. They shield workers from flying chips, sparks, and accidental contact with the chuck or cutting tool, which can cause serious injuries such as cuts, burns, or entanglement. By reducing exposure to these dangers, they create a safer workspace and significantly lower the risk of accidents, aligning with expert safety practices widely recognized in the manufacturing industry.

Beyond safety, these protective devices are critical for regulatory compliance under workplace standards like OSHA in the United States and international guidelines globally. Organizations that fail to comply face potential fines, reputational damage, or even operational shutdowns. At the same time, they improve efficiency by containing debris, minimizing downtime, and keeping the work environment organized. This balance of safety and productivity builds trust, accountability, and professionalism in machine operation.

Types of Guards

Lathe guards come in several designs, each tailored to different machining hazards. The right choice not only improves safety but also enhances workflow efficiency. Operators and managers should evaluate the machine type, job complexity, and risk factors. Selecting a suitable guard ensures long-term compliance and operator confidence. Below are the most common lathe guard options used in shops today.

Chuck Guards

Chuck guards protect the rotating chuck, preventing hands or clothing from accidental contact. They also contain flying chips, reducing the risk of eye or skin injuries. Many designs feature interlocks that stop the machine when the guard is lifted. This balance of safety and accessibility makes them essential in workshops. Their compact build ensures minimal interference with daily machining tasks.

Sliding or Hinged Guards

Sliding or hinged guards cover the cutting zone while allowing easy access. Operators can quickly slide or lift them during adjustments and inspections. This design makes tool changes faster without compromising safety standards. They are especially useful in shops where setups change frequently. Their convenience and reliability have made them a popular guard option.

Fixed Guards

Fixed guards are permanent barriers that stay bolted to the machine. They are best suited for repetitive tasks where setups rarely change. Since they cannot be easily removed, tampering and misuse risks are minimized. These guards offer consistent protection over long production runs. They are widely used in manufacturing environments with standardized operations.

Adjustable Guards

Adjustable guards move with the cutting tool and adapt to various setups. They are useful when working with irregular workpieces or complex projects. Operators can position them closer to the hazard for maximum safety. Their flexibility makes them ideal in toolrooms or custom machining shops. This type of guard balances adaptability with effective risk reduction.

Enclosure Guards

Enclosure guards provide complete coverage for lathes or CNC machines. They are designed to contain chips, sparks, and coolant spray efficiently. These guards are common in high-risk environments with automated operations. Their full protection ensures worker safety and regulatory compliance. For maximum defense, they are the top choice in modern machining.

Compliance and Safety Regulations

Workplace safety authorities worldwide mandate the use of machine guards to protect operators from hazards such as rotating parts, flying chips, or sparks. In the United States, OSHA regulations clearly state that proper guarding must be in place to prevent injuries. European standards like EN ISO 23125 also provide detailed requirements for CNC machines. These global frameworks highlight the importance of consistent protection across all machining environments.

Employers carry the responsibility of ensuring that guards of lathe and other safety devices are properly installed, fully functional, and not tampered with. Regular inspections are essential for maintaining compliance and demonstrating accountability to regulators. By documenting these checks, businesses reduce liability in case of accidents. This proactive approach reflects professionalism while safeguarding both workers and long-term operations.

Installation Best Practices

Proper installation of guards is essential for achieving both safety and operator convenience. Guards should be positioned to cover all hazardous areas while maintaining clear visibility for the user. This balance ensures that protection does not interfere with workflow or precision. Effective installation reduces risks and improves operator confidence during machining tasks.

Durable, transparent materials such as polycarbonate are recommended for guard construction. These materials provide long-lasting protection while allowing operators to monitor the machining process without obstruction. Guards must be designed to move easily for tool changes yet remain secure to avoid accidental removal. This combination of safety and usability enhances both performance and reliability.

Compatibility is another key factor to consider when installing protective equipment. Each guard should be tested to ensure it fits the specific machine model and intended operations. Working with certified suppliers helps guarantee that the installation meets safety standards and regulatory requirements. Properly fitted equipment demonstrates commitment to compliance and long-term operator well-being.

Maintenance and Inspection

Like any safety equipment, guards require regular maintenance to remain effective. If guards are damaged, loose, or neglected, they compromise operator safety and may lead to compliance violations. Proper care ensures that the equipment functions as intended while extending its service life. Consistent attention to safety also reflects professionalism and responsibility in workshop operations.

Daily inspections are an essential step to keep guards in working condition. Operators should check for cracks, replace opaque panels that reduce visibility, and lubricate hinges or sliding mechanisms to maintain smooth operation. Fasteners and brackets must always remain secure, as loose fittings can create serious hazards. These small efforts prevent larger risks and costly downtime.

Benefits

The benefits of lathe guards extend beyond meeting compliance and basic safety requirements. They help reduce downtime by minimizing accidents and debris-related issues, allowing production to continue without interruptions. This efficiency improves overall workflow while lowering the risk of costly delays. As a result, workshops can maintain higher productivity and reliability in daily operations.

They also contribute to operator confidence, giving workers the assurance that they are safe while handling demanding machining tasks. A secure environment encourages focus, precision, and improved output quality. This confidence not only benefits individual workers but also strengthens the overall safety culture. Companies gain trust and credibility when they prioritize employee protection.

Another major advantage is the cleanliness and long-term protection they provide for machines. By containing chips and coolant, guards keep workspaces organized and reduce unnecessary mess. They also protect equipment from debris damage, which extends lifespan and lowers repair costs. Over time, this investment ensures both safer operations and sustainable performance.

Real‑World Example (Experience)

A job shop operating a 15″ manual lathe improved safety by installing an interlocked chuck guard and a carriage-mounted chip shield. Operators were trained to keep the shields properly positioned, and weekly checks were introduced as part of the routine. These measures significantly reduced near-miss reports related to chip ejection. The flip-up window on the guard also made tool changes quicker and more efficient.

To strengthen accountability, the shop documented interlock tests on a monthly form. This practice not only demonstrated compliance but also provided auditors with clear evidence of control effectiveness. By combining training, regular inspections, and record-keeping, the shop enhanced both operator safety and workflow efficiency. The results highlighted the long-term value of proper guard implementation.

Choosing the Right Guard

When selecting a lathe guard, it is important to match the guard to the machine type and size, as well as the frequency of use. Visibility requirements should also be considered to ensure operators can work safely and efficiently without obstruction. The skill level of the operator plays a role, since experienced machinists may require more advanced guard systems. Factoring in the regulatory environment ensures compliance with workplace safety laws and industry standards.

In some cases, custom-built guards may be necessary for unique machines or specialized operations. Working with trusted suppliers who provide certified products is essential, as these guards are tested against recognized safety standards. This not only enhances operator protection but also builds trust in the equipment being used. By relying on proven safety solutions, machinists and workshop owners demonstrate responsibility and commitment to long-term reliability.

Conclusion

Safety in machining requires consistent attention to both equipment and operator protection. Guards serve as a barrier against sparks, chips, and rotating parts that could cause harm. By reducing these risks, they help businesses comply with recognized workplace safety regulations. Maintaining them also shows responsibility toward workers’ well-being. This proactive approach builds trust and credibility in any workshop.

For long-term efficiency, investing in lathe guards is a practical decision. They not only minimize downtime but also prevent costly accidents and damage. A clean, organized environment improves productivity and reduces hazards. Both small workshops and large industries benefit from these safety measures. Prioritizing proper guarding reflects expertise, professionalism, and commitment to safe operations.

FAQs

1. Why are guards necessary?

Lathe guards protect operators from hazards such as flying chips, rotating parts, and accidental contact with the chuck or tool. They are essential for both safety and compliance.

2. Can I operate a lathe without a guard?

Operating a lathe without a guard is unsafe and may violate workplace safety regulations. It exposes operators to significant risks and can result in fines or shutdowns.

3. What materials are used for these protective barriers?

They are usually made with a sturdy metal frame combined with transparent polycarbonate or acrylic panels for strength and visibility.

4. How frequently should protective barriers on a lathe be checked?

Daily checks are recommended before each use. More thorough inspections should be conducted monthly or quarterly to ensure compliance and prevent failures.

5. Do CNC lathes require guards?

Yes. CNC lathes often use enclosure guards that fully contain the machining area. These guards provide the highest level of safety and help with automation processes.