In workshops across the world, lathes remain one of the most important machines for shaping and cutting materials. They are versatile, reliable, and capable of handling an impressive range of turning tasks. But a lathe by itself has limitations. When machinists want to expand its usefulness without buying another expensive piece of equipment, a lathe milling attachment becomes the solution.

By adding this accessory, a lathe can take on certain milling tasks, transforming from a single-purpose machine into a multi-functional tool. It allows operators to cut slots, drill holes, and create profiles that would otherwise require a dedicated milling machine. This balance of cost-effectiveness and versatility explains why milling attachments continue to be popular among both professional machinists and hobbyists.

What a Milling Attachment Actually Does

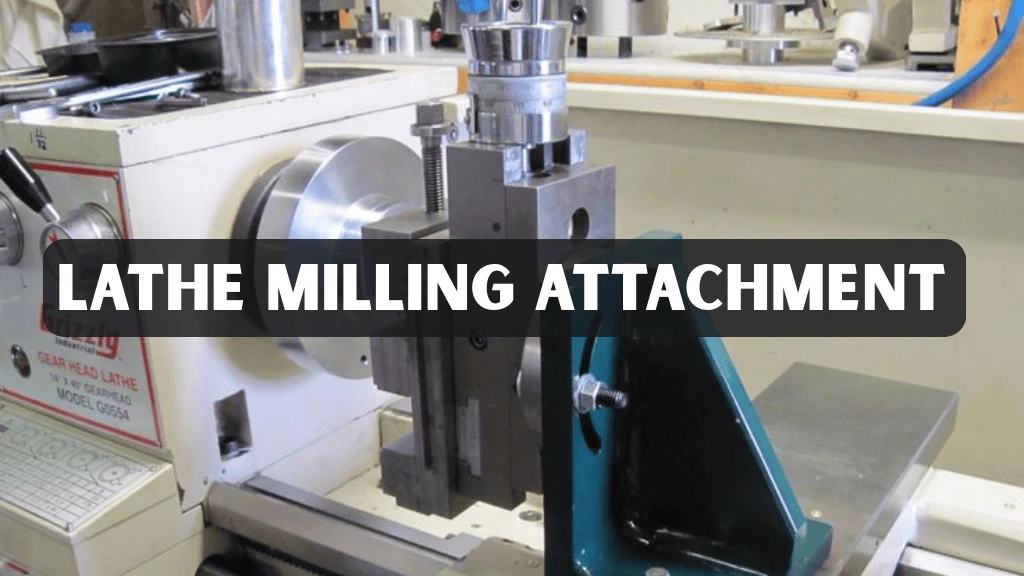

At its core, a lathe milling attachment is designed to mount on the carriage or cross-slide of the lathe. Once installed, it provides vertical or angular motion that enables basic milling operations. Instead of the workpiece being rotated, as in normal lathe use, the attachment allows a cutting tool to move in ways that mimic a milling machine.

This setup can be surprisingly effective. While it will never offer the same rigidity or precision as a standalone mill, it opens up a range of operations that would otherwise be impossible on a lathe. For small-scale workshops, it is often the only practical way to achieve milling functions without investing in larger equipment.

Why Many Machinists Choose This Option

One of the main reasons machinists adopt milling attachments is financial. Milling machines are expensive, especially those built for precision work. A milling attachment, by contrast, can often be purchased for a fraction of the cost while still enabling the most essential operations.

Another reason is space. Many home shops or small professional environments simply cannot accommodate multiple large machines. A lathe already occupies a central place in the workshop, and with an attachment, it can take on additional responsibilities without requiring extra floor space.

Beyond cost and space considerations, there is also convenience. A machinist who only occasionally needs to cut a slot or drill a precise hole does not always require a full milling machine. Instead, they can rely on the attachment when necessary and continue to use their lathe for the majority of work. For those just entering the field, it also provides an excellent introduction to milling techniques before investing in larger, more complex machinery.

Types of Lathe Milling Attachment

Different designs of milling attachments exist, each catering to specific machining needs. The most common option is the vertical slide attachment, which mounts on the cross-slide and provides vertical movement. This design is simple to set up and can also be adjusted for angular cuts, making it a practical choice for general-purpose machining. Many machinists rely on it as an entry-level solution when adding milling functions to their workshop.

For more complex projects, machinists often turn to compound slide or swivel attachments. These designs allow for angular positioning and even rotation of the head, offering greater flexibility in producing angled or intricate cuts. A lathe milling attachment of this type is particularly valued by hobbyists and small manufacturers who need versatility without investing in a dedicated milling machine. Based on industry feedback, these setups strike a balance between adaptability and cost-effectiveness.

In industrial environments, heavy-duty attachments are preferred because of their rigidity and stability. These models are engineered to handle higher workloads and tighter tolerances, often demanded by aerospace and automotive sectors. Though more expensive, their durability and precision justify the investment. Trustworthy manufacturers typically provide technical specifications and long-term performance data, ensuring machinists can choose the right attachment with confidence.

Benefits That Stand Out

The appeal of a milling attachment is not limited to affordability and space saving, though those factors are significant. What makes the accessory especially valuable is its ability to extend the range of tasks that can be performed on a lathe.

With the right attachment, a machinist can cut keyways into shafts, machine slots for gears, or prepare flat surfaces for assembly. Instead of outsourcing small milling jobs, they can handle them in-house, saving both time and money.

For hobbyists, the benefits are equally compelling. A person working on model engines, custom parts, or prototypes gains access to milling without needing a dedicated machine. The attachment becomes a bridge between basic turning and more advanced fabrication techniques.

The Limitations You Need to Know

Despite the many advantages, a milling attachment is not without drawbacks. The most notable is rigidity. A lathe is not designed with milling forces in mind, and attachments cannot match the stability of a dedicated mill. This means that heavy cuts, especially in harder metals, can cause chatter or vibration that reduces accuracy.

There are also restrictions on cutting depth. Attachments are best suited for lighter work and may struggle with larger projects. Setup can be another challenge. Unlike a milling machine, which is built for straightforward alignment, a lathe with an attachment requires careful preparation to ensure proper accuracy.

These limitations mean that while attachments are excellent for certain tasks, they cannot replace a full-scale milling machine in industrial settings. However, for smaller projects, repairs, and occasional use, they perform admirably.

Examples of Real-World Use

A small repair shop often needs to create custom shafts and cut keyways. Instead of outsourcing these jobs, a milling attachment allows them to handle the work in-house, saving time and lowering costs. This improves efficiency while keeping control over project quality.

For hobbyists, the benefits are just as clear. A model maker building steam engines can use the attachment to cut slots and surfaces with enough precision for fully functional parts. While it cannot match the accuracy of an industrial milling machine, it provides more than enough capability for small-scale engineering.

These examples show why attachments remain valuable. They may not replace a dedicated mill in every setting, but for workshops and enthusiasts seeking affordable versatility, they are often the smartest choice.

Factors to Consider Before Buying

When selecting a milling attachment, compatibility is critical. The attachment must match the size and design of the lathe, including swing, carriage dimensions, and cross-slide capacity. Choosing the wrong size can lead to instability or even make the attachment unusable.

The materials you plan to machine should also influence your decision. Some attachments are lightweight and better suited for aluminum or brass, while others are stronger and can handle mild steel with reasonable accuracy. Rigidity should be a major factor as well, since a sturdier design reduces vibration and helps achieve better surface finishes.

Ease of adjustment is another consideration. Attachments with fine feed controls and angular settings provide more flexibility and reduce the time needed to achieve precise results. Finally, budget plays a role. While inexpensive models are available, higher-quality attachments often justify their cost by delivering improved durability and performance.

How to Set Up and Use It Effectively

Installing a lathe milling attachment requires careful preparation and precise alignment. The attachment must be mounted securely on the lathe carriage to eliminate vibration, which can compromise accuracy. Once secured, alignment with the spindle should be double-checked, as even the smallest deviation can result in noticeable errors in the final workpiece. Experienced machinists often use dial indicators to verify setup accuracy.

Equally important is the condition of the cutting tools being used. Sharp tools reduce chatter, improve surface finish, and extend the life of both the tool and the attachment. Operators are encouraged to begin with light cuts, particularly when working with tough alloys or hardened steel. This practice not only protects the equipment but also builds confidence in handling more complex jobs.

Professional workshops often stress the importance of monitoring alignment throughout longer machining sessions. Small shifts can accumulate over time, which is why periodic checks are considered best practice. Patience and precision during setup may seem time-consuming, but industry experience consistently shows that these steps directly impact the overall quality, safety, and reliability of the machining results.

Safety Considerations

Like all machining processes, safety is a critical consideration when using attachments. Operators should wear protective eyewear, secure long hair, and avoid loose clothing or jewelry around rotating equipment. Workpieces must always be clamped firmly in place before milling begins, as holding material by hand is unsafe and risks both injury and poor accuracy.

Another essential step is avoiding overload of the equipment. The attachment is designed for controlled and moderate operations, not for pushing beyond its limits. Excessive force increases vibration, dulls tools more quickly, and raises the chance of breakage or accidents. Industry experts recommend steady, measured cuts that maintain balance between speed and precision.

Regular inspection further strengthens safety and performance. Bolts, fasteners, and mounting points should be checked before and during operations to confirm stability. Experienced machinists emphasize that these small preventive steps greatly reduce the chance of accidents while extending the life of the attachment. By following these precautions, operators can work both confidently and safely.

Comparing Attachments with Milling Machines

The differences between an attachment and a dedicated milling machine are clear. A milling machine is built for rigidity, precision, and heavy workloads. It can handle deep cuts, complex shapes, and continuous production without difficulty. An attachment, on the other hand, is designed for lighter work and occasional use.

This does not make it less valuable. For machinists who only need milling capabilities from time to time, the attachment is a practical and efficient choice. But those who rely heavily on milling in their operations will quickly find a full machine indispensable.

The decision ultimately comes down to workload, budget, and available space. Attachments and milling machines serve different roles, and many machinists find themselves using both depending on the job at hand.

Insights from Experienced Machinists

Feedback from machinists in professional forums and workshops often highlights that these tools should be considered an addition rather than a full replacement for a milling machine. Many users appreciate the ability to perform operations like keyway cutting, slotting, and light surfacing, but they also caution against expecting the same level of rigidity and precision found in dedicated mills. This balanced view underscores their practical value.

Real-world examples further strengthen this perspective. One machinist described how he successfully produced custom gears for a restoration project using only his lathe and attachment, saving both time and project costs. While the results may not match industrial tolerances, the solution proved more than adequate for repair and restoration purposes, demonstrating its versatility in smaller workshops.

Across multiple communities, the shared experience reinforces a common conclusion: these attachments fill a unique and valuable role in machining. They bridge the gap between basic lathe operations and advanced milling tasks, offering hobbyists, small business owners, and repair professionals a cost-effective way to expand their capabilities without investing in large, expensive equipment.

Conclusion

A lathe milling attachment can be a practical investment for machinists looking to extend the capabilities of their lathe. By adding this tool, operators gain access to a wider range of machining tasks without the need for separate, large-scale equipment. This not only reduces upfront costs but also saves valuable workshop space, which is especially important for smaller shops or home-based setups.

While it cannot fully replicate the rigidity and precision of a standalone milling machine, the attachment provides an effective middle ground. For hobbyists, repair shops, and professionals who only occasionally require milling functions, it delivers enough versatility to perform slotting, keyway cutting, and light surfacing with confidence. This balance of affordability and functionality makes it a popular choice among practical machinists.

Frequently Asked Questions

What operations can be done with a milling attachment?

You can perform light milling tasks such as slotting, drilling, surfacing, and cutting keyways.

Is it worth buying for a small workshop?

Yes. For hobbyists or workshops with limited space, it provides an affordable way to access milling functions.

How accurate is it compared to a milling machine?

It offers good accuracy for light tasks but cannot match the rigidity and precision of a dedicated mill.

Can beginners use it effectively?

With proper setup and patience, beginners can operate a milling attachment successfully while learning milling techniques.

Does it replace a milling machine?

No. It complements a lathe but is not a substitute for a standalone mill in demanding environments.