Woodturning has evolved significantly with the introduction of advanced tools and accessories, and one of the most impactful innovations is the lathe vacuum chuck. For both beginners and seasoned woodworkers, this tool has transformed the way projects are held, shaped, and finished. Traditionally, mechanical chucks and faceplates were the go-to methods for securing wood on a lathe, but these options often required screws or left marks that needed additional sanding. Vacuum chucking changed that by offering a secure, non-damaging grip that saves both time and effort.

This article explores everything you need to know about vacuum chucking for wood lathes. From understanding how it works to exploring different setups, benefits, and real-world applications, you will gain insights backed by expertise, practical experience, and trusted sources in woodworking. By the end, you will understand why so many woodturners consider this tool to be an indispensable addition to their workshop.

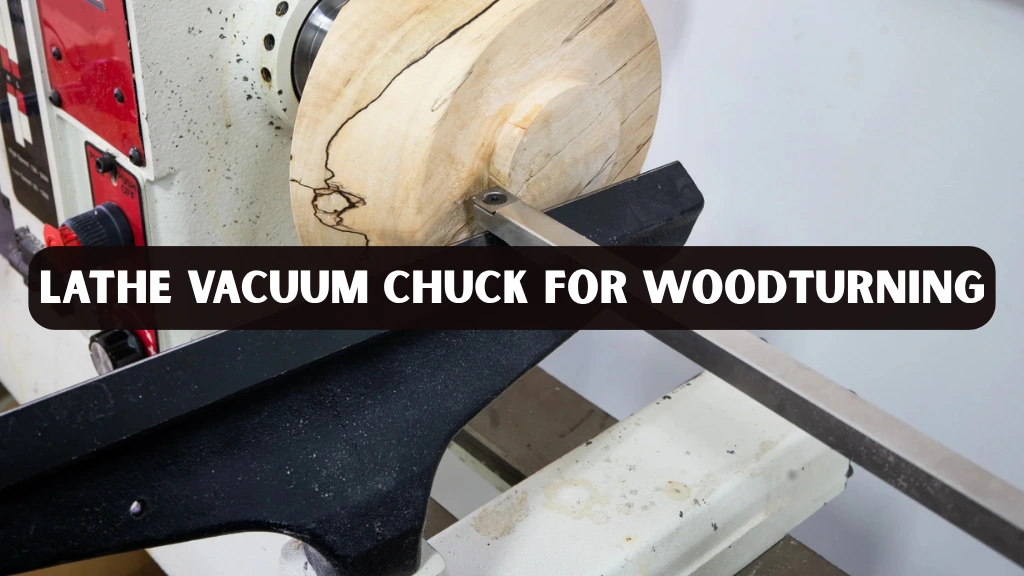

What Is a Lathe Vacuum Chuck?

A lathe vacuum chuck is a work-holding device that uses suction created by a vacuum pump to grip a piece of wood securely against the headstock of the lathe. Unlike mechanical chucks that rely on jaws or screws, vacuum chucks create a negative pressure environment, pulling the wood tightly against a padded surface. This eliminates the need for external clamps or hardware that could damage the surface of the workpiece.

The principle is simple yet powerful. By generating suction inside a sealed system, the vacuum chuck ensures that the wood remains stable during turning. This method is particularly useful for finishing operations, where the goal is to avoid marks or indentations left by traditional holding tools. The result is cleaner, smoother projects with less post-turning cleanup.

How It Works

At its core, the system relies on three main components: a vacuum pump, a rotary adapter, and the chuck itself. The vacuum pump generates the suction, while the rotary adapter transfers this suction from a stationary source to the spinning spindle. Finally, the chuck, often padded with foam or rubber, creates a tight seal against the wood surface.

When activated, the pump removes air from within the chuck, lowering the pressure inside. The surrounding atmospheric pressure then pushes the wood against the chuck, holding it firmly in place. Because the grip is evenly distributed, it reduces the risk of splitting or cracking delicate wood pieces.

Many beginners question whether suction is strong enough to hold heavy or irregular shapes. In practice, modern systems are capable of generating a grip strong enough for most woodworking tasks, including bowls, platters, and segmented pieces. With proper setup, the system is both safe and reliable.

Advantages of Vacuum Chucking

One of the main benefits of using a lathe vacuum chuck is the ability to finish the bottom of bowls and other vessels without leaving marks. Traditional holding methods often leave screw holes or jaw impressions that require sanding or patching afterward. A vacuum chuck completely removes this issue, ensuring a smooth, seamless finish on every piece. This not only saves time but also enhances the overall quality of your work.

Another major advantage is the speed and convenience it offers. Mounting a workpiece on a vacuum chuck takes only seconds compared to the adjustments required by mechanical grips. This allows woodturners to switch between projects more efficiently, improving productivity during long sessions. It’s an especially valuable tool for those who work on multiple pieces or production runs.

Additionally, the even pressure distribution helps prevent damage to delicate materials such as thin bowls or spalted wood. Traditional methods can easily crack or distort these fragile pieces under tension, but a vacuum chuck applies gentle, uniform holding power. Many woodturners also appreciate how this technique expands creative possibilities, allowing them to shape and refine their designs with greater freedom and confidence.

Choosing the Right System

When selecting a vacuum chuck system, several factors should be considered. First, evaluate the size of the projects you typically turn. Smaller bowls and platters can be held securely with compact systems, while larger projects may require higher suction power and wider chuck surfaces.

The type of pump is another key consideration. Venturi systems, which use compressed air to generate suction, are affordable and effective but require a strong air compressor. Electric vacuum pumps, while more expensive, are quieter and provide consistent suction over longer sessions. Each option has its trade-offs, and the right choice depends on your workshop setup and budget.

Durability and build quality also matter. Chucks made from anodized aluminum or steel tend to last longer, while foam or rubber seals should be easy to replace. A system that allows quick changes between different chuck sizes can also make your work more versatile.

Real-World Experience

Many experienced woodturners have shared how vacuum chucking has improved their workflow. For instance, one craftsman noted that finishing the base of a salad bowl used to take nearly as long as shaping the entire bowl itself. After adopting vacuum chucking, the process became smoother and reduced his finishing time by half.

Another example comes from a woodturning club demonstration where members compared traditional faceplates with vacuum chucking. The consensus was clear. While faceplates still had their place in roughing work, vacuum chucks excelled in finishing and detail work. Such real-world experiences demonstrate why vacuum systems are considered essential by many professionals.

Setting Up the Equipment

Proper installation is critical for both safety and performance. Begin by attaching the rotary adapter securely to the headstock spindle, as this allows the vacuum line to connect without disrupting the lathe’s rotation. Once in place, connect the adapter to the vacuum pump using the correct hoses and fittings. Taking time to ensure tight, leak-free connections helps maintain stable suction during operation.

After setting up the vacuum system, attach the chuck carefully. Before switching on the pump, inspect the foam or rubber gasket to confirm it’s clean, intact, and free from debris. When suction is activated, press the workpiece against the chuck and make sure it holds firmly before turning on the lathe. This step is essential for preventing movement or vibration while turning.

Many woodturners include a vacuum gauge to track pressure levels throughout their work. This offers peace of mind that suction remains steady and suitable for the piece being turned. Consistent maintenance, such as cleaning filters and inspecting seals, significantly extends the system’s lifespan and ensures dependable performance for every project.

Applications in Woodturning

The most common use of a lathe vacuum chuck is for finishing the bottoms of bowls and platters. After shaping the main body, the workpiece can be remounted on the chuck to remove the tenon or recess left from earlier holding methods. This ensures a flawless base and gives the finished piece a clean, professional appearance. It’s a preferred approach among woodturners who prioritize precision and surface quality.

Vacuum chucking is also highly effective for delicate sanding tasks. Since the piece is held securely without screws or clamps, it stays stable while sandpaper is applied with minimal vibration. This controlled environment helps achieve smoother finishes and reduces the risk of damaging thin or fragile workpieces. It’s particularly valuable when working on hollow forms, segmented pieces, or other intricate designs that require accuracy.

Beyond woodworking, vacuum systems have proven their usefulness in other crafts as well. Many artisans use them for handling materials such as glass, resin, or lightweight metals during polishing or coating processes. This adaptability highlights the versatility of the technology, making it a valuable addition to workshops across multiple creative disciplines.

Challenges and Limitations

While highly effective, vacuum chucking does come with a few challenges. Porous woods like oak or ash can leak air, which weakens suction and reduces holding power. To overcome this, many woodturners seal the surface with masking tape or apply a light coat of finish before mounting. This small step greatly improves performance and ensures a more secure grip during turning.

Irregularly shaped workpieces can also make it difficult to achieve an airtight seal. For such projects, experienced turners often rely on custom gaskets or specialized adapters designed for unique contours. It’s also recommended that beginners start at slower lathe speeds until they’re fully comfortable with the setup. This not only improves safety but also helps build confidence with the system.

Lastly, cost can be a concern, especially for hobbyists setting up their first vacuum system. Between the pump, rotary adapter, and chuck, expenses can range from a few hundred to over a thousand dollars. Still, many woodturners find that the time saved, improved efficiency, and flawless results make the investment well worth it over time.

Conclusion

The lathe vacuum chuck represents a significant advancement in woodworking, allowing turners to secure projects without damaging surfaces or relying on traditional mechanical methods. By harnessing atmospheric pressure and vacuum suction, it provides a firm, evenly distributed grip that enhances both safety and precision. This technology is particularly valuable for finishing delicate pieces, as it reduces the risk of splits or marks while supporting creative freedom during turning.

Whether you are a beginner looking to refine your finishing process or a professional seeking greater efficiency, vacuum chucking opens a wide range of possibilities. From bowls to hollow forms, its versatility makes it an essential tool in modern woodturning. Supported by expert recommendations, positive reviews, and practical experience, it offers reliable performance while saving time and elevating the overall quality of craftsmanship.

FAQs

How strong is the grip of a vacuum chuck?

A properly installed system generates enough suction to hold most small and medium-sized bowls securely. While not ideal for heavy roughing, it is more than adequate for finishing and light cutting.

Can this system work with porous wood?

Yes, but results vary. Porous woods may require sealing with tape, wax, or finish before achieving a reliable hold. Many turners use these methods successfully.

Is a vacuum pump noisy?

Venturi systems tend to be noisier due to their reliance on compressed air. Electric pumps, while more expensive, generally operate quietly and are better suited for extended use.

How safe is vacuum chucking?

When set up correctly, it is very safe. Always verify suction before starting the lathe and begin at low speeds. With experience, you can confidently turn at higher speeds.

Is it worth the investment for hobbyists?

For hobbyists who frequently turn bowls, platters, or detailed projects, the time savings and quality improvements make the investment worthwhile. Those who turn only occasionally may prefer traditional holding methods until their skills and project needs expand.