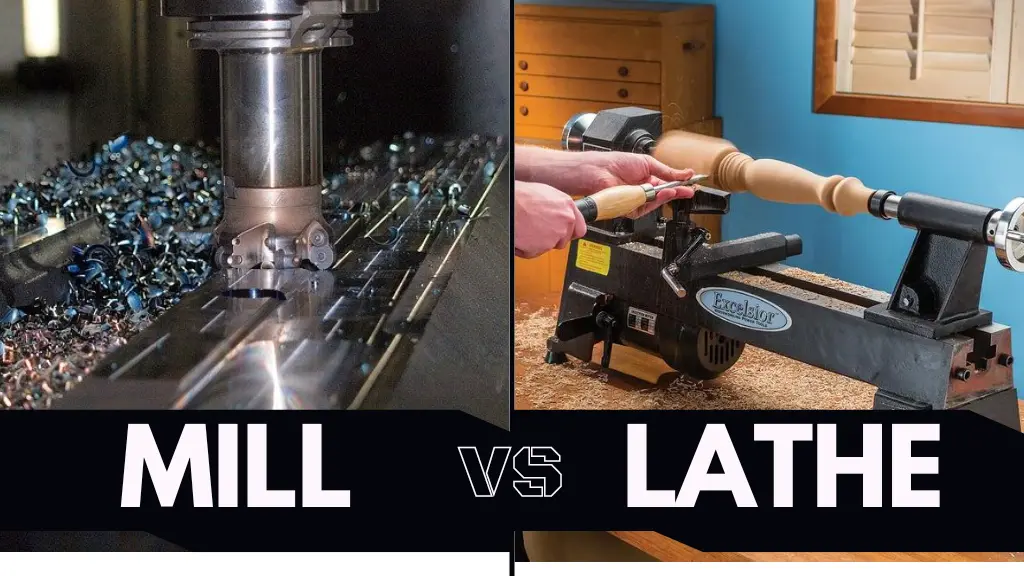

We’ll compare a lathe vs mill machine, looking at crucial difficulties and use cases so you can make the right call for your shop. Lathes are generally lower and have smaller corridors than their metalworking counterparts. Still, they both calculate the rotational power of the mounted workpiece to remove the material as it’s exposed to a single-bladed slice tool.

Overview of Lathe vs Mill

A lathe and mill machine are the two most meaningful workhorses of any comprehensive engine store. With either one, you can achieve numerous of your abecedarian machining ways.

Each is great at slicing away essence.

But there’s an essential distinction between these machines, And that contrast means that each bone is best suited to distinct operations, operations, and systems.

What Is a Lathe?

A lathe is a large machine suggesting a standard workbench and conforming to nearly a dozen corridor beds, carriages, headstocks, tailstocks, faceplates, etc. It’s designed to rotate a workpiece against a single-bladed slice tool. After the workpiece is mounted on the lathe, it is turned against a single-bladed slice tool.

The slice tool remains stationary, but the workpiece rotates against it to remove material. Depending on the material they intend to remove, lathes can be either woodworking or metalworking.

What Is a Milling Machine?

A milling machine is a machine used to remove material from a workpiece by feeding the workpiece against a multi-bladed or- refocused slice tool. Milling machines are higher than lathes but have a shorter length, allowing manufacturing companies to place them in small spaces.

Away from shape and size, however, the primary difference between lathes and milling machines is their system of operation. With lathes, the workpiece rotates against a stationary slice tool. With milling machines, a stationary workpiece is exposed to a rotating slice tool.

Also, the slice tool used in milling machines generally has several blades or points. The slice tool used in lathes typically has a single edge. With multiple blades or points, milling machines are suitable for grinding down material from the workpiece.

Lathe vs Mill in The Working Method

Both machines can be discerned concerning their working system, contrary to each other.

Lathe Machine: The lathe machine slice tools stay stationary, and the essence or wood object is rotated to make colorful shapes. The chuck on the headstock holds the workpiece and turns it continuously, and the tool holder holds the slice tool, which is tensed precisely so that it can’t move.

Milling Machine: In the milling machine, the knife is placed on a spindle or dome and can rotate at high speed. Without turning, the blade has no other movement. The workpiece is gripped in the board of the engine. The movement of the table controls the feed of the workpiece.

When Should You Use A Lathe?

A lathe is a powerful tool used for shaping materials into round or symmetrical forms with high precision machining. It works by rotating the workpiece while cutting tools perform turning operations to remove excess material from the outer surface. Common tools used in these operations include facers, grooving tools, and various cutting heads, each designed to achieve specific contours and finishes.

Beyond external shaping, a lathe also supports interior material removal. This is done using a boring bar or by machining the flat face opposite the chuck. These techniques are useful for creating holes, cavities, or internal grooves. Still, it’s crucial to ensure the structure remains safe and stable during the process to avoid tool chatter or workpiece damage.

Turning ways on a lathe machine include:

- Core facing

- Threading

- Boring

- Creating grooves, vestments, and tapers

- Drilling center holes on turned pieces

When Should You Use A Milling Machine?

While a lathe is a way for cylinders and harmony, a shop is ideal when machining involves creating flat shells and irregular shells, gears, grooves, and other features.

With all the different slice tools available, you can use your shop for a wide array of operations, including

- Boring holes

- Cutting places

- Shaping intricate part geometries

- Drilling

You might suppose a drill press for that last task on the list, but a shop allows you to drill holes much more precisely.

Which One Is Better?

In reality, the answer is neither and both. They’re both perfect complements to one another, like peanut adulation and jelly.

- An essence lathe and a milling machine are also crucial complements to the abecedarian metalworking tools in your home machine shop. The lathe is for your spherical and symmetrical shapes. The shop is for non-cylindrical workpieces.

- They work together to produce complex shapes that can be used on wood, essence, plastic, or other materials. But you might have a place and deposit for one of them.

- The decision will come down to various factors—systems you want to do, machining operations you wish to use, and effects like headroom in your shop.

- Depending on all that, a lathe is a good starting point for potterers. Incompletely because, with the right chops, you can do( nearly) all the milling you need on a lathe. But not inescapably vice versa.

Conclusion

To be a logical machinist, you must have a well-founded machine that can pave your path. And copping a device according to your requirements is also an important task. There are subtle differences between a lathe and a milling machine, which many people don’t understand or know. We’ve tried to cover all the affiliated differences between them so that it becomes easier for you to separate between them. I hope this helps you.

FAQ’s

What can be made of a lathe vs. a milling machine?

Lathe: Spherical corridor, symmetrical factors, threading, rotational harmony.

Mill: Flat shells, irregular shapes, multi-dimensional factors,non-cylindrical features.

When to Use Lathe vs Milling Machine?

Lathe: Spherical work, rotational harmony, threading, simple symmetrical designs.

Mill: Flat shells, complex shapes,multi-axis machining,non-cylindrical features.

How do befit lathes and milling machines vary in their primary functions?

Lathes are for turning and shaping spherical corridors, while mulling machines are for cutting and shaping solid accouterments with rotating knives.