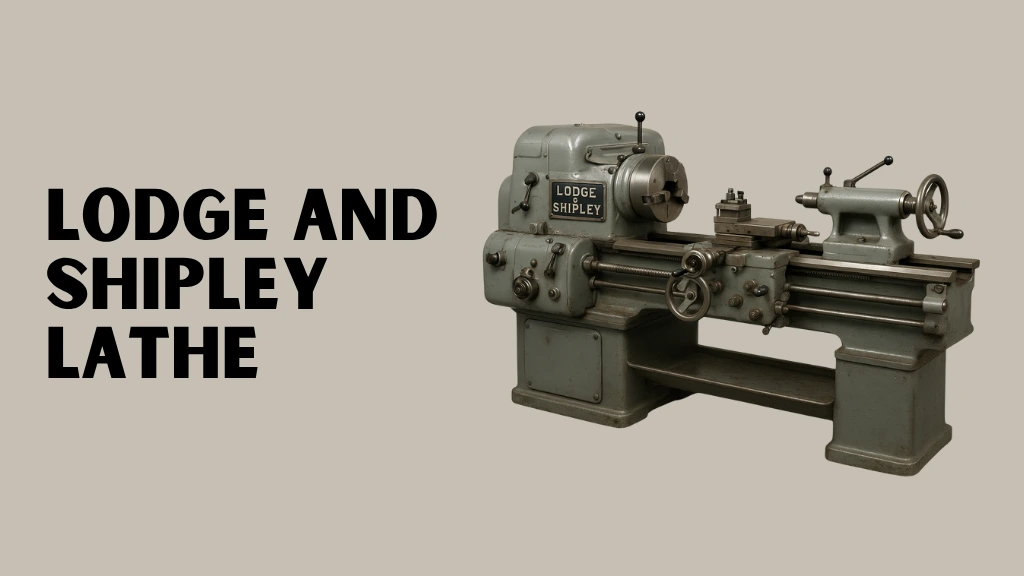

The Lodge and Shipley lathe stands as a hallmark of American engineering, renowned for its durable construction, precise machining capabilities, and versatile applications. Built in Cincinnati, Ohio, these machines have served a wide range of industries, from automotive manufacturing to aerospace, for more than a century. Their enduring reputation is based on reliability, accuracy, and superior craftsmanship, making them a trusted choice for machinists and industrial operations seeking high-performance equipment.

Beyond professional shops, these lathes have also attracted collectors and hobbyists who value both their historical significance and mechanical excellence. This guide delves into the history, technical specifications, practical benefits, maintenance practices, and lasting legacy of Lodge and Shipley machines. Whether you are a seasoned machinist or an enthusiast, understanding the features and advantages highlights why these lathes continue to hold an esteemed place in the world of precision machining.

History of Lodge and Shipley

Lodge and Shipley was founded in 1891 by William Lodge and William Shipley with the goal of producing high-quality lathes. From the beginning, the company focused on precision engineering and manufacturing excellence, which quickly earned them a reputation for building durable and reliable machines. By 1893, they had discontinued other machine-tool lines to concentrate solely on lathe production, ensuring consistent quality across their product line.

Their guiding principle, captured in the motto “Good Lathes Only,” reflected a strong commitment to craftsmanship and the rigorous standards of American manufacturing. Early machines were quickly adopted by machine shops and industrial facilities, helping the company establish a solid presence in the market. These initial years laid the foundation for a legacy that would influence the machine tool industry for decades.

Throughout the 20th century, Lodge and Shipley continued to innovate, introducing a wide range of lathe models to meet the evolving needs of industrial machining. From small tool-room lathes to large-capacity engine lathes, their machines were recognized for precision, durability, and reliability. Standardized components simplified maintenance and repairs, extending the operational life of each machine. This combination of innovation, practicality, and quality cemented their reputation as leaders in American lathe manufacturing.

Key Models and Specifications of Lodge and Shipley Lathe

Lodge and Shipley lathes have been produced in a variety of models to suit different workshop and industrial needs. Each machine reflects the company’s focus on precision, durability, and versatility. From small tool-room lathes to large-capacity industrial machines, they provided reliable and accurate performance. Understanding the specifications of each model shows why these lathes remain highly regarded by machinists and collectors.

Model A Series

The Model A series was one of Lodge and Shipley’s earliest offerings, designed for smaller workshops and tool rooms. Swing capacities ranged from 12 to 16 inches, with bed lengths up to six feet, providing a versatile platform for various machining tasks. These lathes featured manual feed mechanisms and geared headstocks to ensure smooth, precise operation. Precision-ground bedways enhanced stability and cutting accuracy for detailed and repetitive work.

Many Model A lathes are still in use today, highlighting their durable construction and lasting performance. Compact yet robust, they allowed smaller shops to achieve high-quality machining results. These lathes were valued for reliability, ease of maintenance, and consistent performance. Collectors now often restore them, preserving both their historical and functional significance.

Powerturn Series

The Powerturn series was developed for industrial-scale operations that required both power and accuracy. Swing capacities ranged from 16 to 24 inches, with bed lengths extending up to 13 feet for larger components. Motor options between 15 and 20 HP enabled high-speed spindle operation up to 2000 RPM. Replaceable bedways simplified maintenance and extended machine life in demanding production environments.

Powerturn lathes were widely used in automotive and heavy engineering industries. Their heavy-duty construction and multiple speed ranges allowed versatility for different materials and component sizes. These machines delivered consistent performance under prolonged workloads, reinforcing Lodge and Shipley’s reputation. Today, they are valued for both industrial utility and historical significance.

T Series and Large-Capacity Lathes

The T Series and other large-capacity lathes were designed for extremely heavy machining tasks. Swing sizes reached 60 inches, with bed lengths up to 30 feet for large components. Motors up to 50 HP ensured high accuracy and performance even under intense workloads. Features like dual tracers, automatic threading, and specialized tooling capacity increased operational efficiency.

Industries requiring heavy-duty, precise machining relied on these lathes for decades. The T Series combined precision engineering with functional durability, producing accurate results on large parts. Their robust construction and advanced capabilities set a benchmark for industrial lathes. Collectors and engineers continue to appreciate their historical and practical value.

Features and Advantages

The Lodge and Shipley lathe is celebrated for its key advantages that have contributed to its enduring popularity among machinists. Its solid construction provides exceptional stability during operation, minimizing vibration and enabling precise cuts. Precision engineering, including ground bedways and high-quality components, ensures consistent machining accuracy across various tasks. These qualities make the lathe suitable for a wide range of applications, from small tool rooms to large industrial shops.

Versatility and longevity are additional hallmarks of these machines. Many Lodge and Shipley machines remain operational decades after their manufacture, demonstrating remarkable durability. This makes them not only a reliable choice for industrial users but also a sought-after item for collectors who value historical significance and lasting performance. The combination of precision, strength, and practical utility underscores the lathe’s reputation as a cornerstone of American machining excellence.

Maintenance and Care

Maintaining a Lodge and Shipley machine is essential to ensure long-term performance and precision. Regular lubrication of all moving parts prevents excessive wear, while frequent cleaning removes debris that could cause corrosion or damage. Periodic inspections of mechanical and electrical systems help detect potential issues early, allowing for timely repairs. Proper alignment of the headstock, tailstock, and carriage is also critical to maintain accurate and smooth cutting operations.

Despite their robust construction, these lathes may experience issues over time. Chatter, often caused by worn bearings or improper setup, can affect the smoothness of cuts. Misalignment of the bedways or worn components may lead to inaccurate machining, while electrical problems such as motor or wiring faults can disrupt operations. With careful maintenance and timely troubleshooting, these machines can continue to deliver precise performance for many decades.

Legacy and Collectibility

Lodge and Shipley lathes are highly regarded among collectors and vintage machinery enthusiasts because of their historical significance and superior build quality. These machines are often sought for restoration and display, showcasing the craftsmanship, precision, and mechanical ingenuity of early American engineering. Restored lathes preserve a piece of industrial history while still providing functional equipment capable of high-precision machining.

Collectors and hobbyists frequently highlight their restorations in online communities and auction sites, demonstrating the enduring appeal and value of these machines. Their combination of durability, accuracy, and historical importance ensures that they remain prized possessions for both enthusiasts and professionals alike.

Real-World Applications

These lathes have been employed across a variety of industries, demonstrating their versatility and reliability. In the automotive sector, they played a key role in producing engine components, drive shafts, and precision housings. Aerospace companies also relied on these machines for high-precision turbine blades, structural components, and complex machined parts. Their stability and accuracy made them valuable tools for both production and prototyping tasks.

Even today, many independent machinists and hobbyists continue to use a Lodge Shipley lathe for precision metalworking projects. Their robust construction and timeless design allow for consistent performance across a range of materials and applications. This enduring utility highlights why they remain respected and sought after, combining historical significance with practical functionality.

Conclusion

The Lodge and Shipley lathe represents a benchmark in American industrial engineering, combining strength, precision, and adaptability. These machines provide reliable performance in professional machine shops, industrial production facilities, and collector workshops alike. Their enduring design and robust construction ensure long-term functionality, making them a trusted choice for generations of machinists.

Investing in a Lodge Shipley lathe offers both historical significance and practical utility. The legacy of these machines reflects engineering excellence and continues to inspire modern manufacturing practices. With a combination of precision, durability, and versatility, they remain valuable tools for professionals, hobbyists, and collectors who appreciate both performance and heritage.

FAQs

What is the history behind Lodge and Shipley machines?

Founded in 1891 by William Lodge and William Shipley, the company became renowned for high-quality lathes and precision craftsmanship, eventually focusing solely on lathe production.

What are the key features of the Powerturn series?

The Powerturn series features heavy-duty construction, multiple spindle speed options, replaceable bedways, and high motor power, making them suitable for demanding industrial applications.

How can I maintain a Lodge Shipley lathe ?

Maintaining these lathes requires regular lubrication, cleaning, alignment checks, and periodic inspection to ensure smooth and precise operation over many years.

Are Lodge & Shipley lathes still in production?

The company ceased operations in the mid-20th century, but its machines are still widely used, restored, and collected due to their reliability and historical value.

Where can I find manuals for Lodge Shipley machines?

Manuals are accessible through vintage machinery archives, specialized online retailers, and collector communities dedicated to machine restoration.