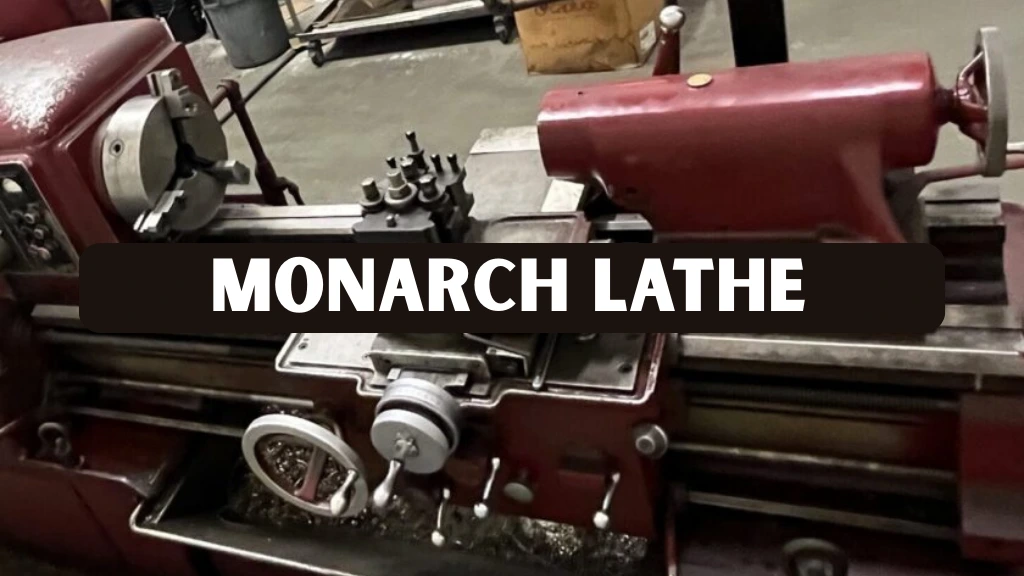

The Monarch lathe has earned a reputation as one of the most trusted names in precision machining. For decades, these machines have been relied upon by professional machinists, hobbyists, and collectors thanks to their exceptional accuracy, long-lasting reliability, and versatile capabilities. Designed to handle both complex industrial tasks and delicate precision work, they are suitable for a wide range of applications, from aerospace components to home workshops. The enduring popularity of these machines reflects over a century of experience in producing tools that meet the highest engineering standards.

Understanding the features, history, and practical uses of this lathe is essential for anyone looking to make an informed investment. This guide draws on expert insights, historical context, and verified technical information to provide a comprehensive overview. Readers will gain practical advice on buying, maintaining, and operating the machine, ensuring safe and efficient use in both professional and hobbyist environments.

History

Monarch was founded in 1909 and quickly became recognized as a leader in precision lathe manufacturing. From its earliest years, the company earned a reputation for producing machines that were durable, reliable, and capable of high-precision work. The early Monarch lathes were manually operated and built to handle heavy industrial workloads, featuring cast iron beds that ensured long-term stability and performance.

One major milestone in the mid-20th century was the release of the Monarch 10EE, which became the company’s flagship and an iconic machine in the machining industry. Its electronic lead screw drive allowed machinists to achieve superior tolerance and repeatability. During the rapid growth of aerospace, automotive, and toolmaking, this innovation positioned Monarch as a preferred choice for demanding applications.

Over the decades, Monarch continued to evolve its designs to meet changing industry needs. By integrating CNC (Computer Numerical Control) technology, the company adapted to the requirements of modern manufacturing while still retaining its commitment to precision. Today, both vintage Monarch and modern CNC versions coexist in workshops worldwide. A notable detail is that even aerospace companies still rely on vintage 10EE machines to produce high-precision components, a testament to the enduring quality of Monarch’s engineering.

Why Choose a Monarch Lathe

A Monarch lathe is valued for the way it combines accuracy, durability, and adaptability. These machines are capable of maintaining tolerances measured in thousandths of an inch, which makes them essential in applications where exacting standards are critical. The robust construction, typically made from heavy-duty cast iron and reinforced materials, allows them to withstand decades of continuous use with minimal wear.

Adaptability is another defining trait. While these lathes are primarily designed for metalworking, they are also used in educational institutions and smaller workshops that may handle a combination of metal and wood projects. A practical example involves a small automotive workshop that integrated a Monarch 10EE to produce custom engine parts. Within weeks, the shop reported an improvement in both efficiency and precision, proving how these machines enhance productivity across diverse settings.

The longevity of these machines also plays an important role in their value. Unlike many modern tools that may be replaced after a decade, a well-maintained unit can remain reliable for 40, 50, or even 70 years. That longevity explains why they are equally prized by collectors, industrial professionals, and hobbyists who understand the value of durable craftsmanship.

Popular Monarch Models

The Monarch brand has produced numerous models over more than a century, each designed to serve different purposes. Understanding the distinctions between these models can help buyers and machinists choose the best option for their needs.

Monarch 10EE: The Iconic Model

The Monarch 10EE remains the most recognizable and celebrated model. Known for its unmatched precision, reliability, and smooth operation, the 10EE has been a staple in industries such as aerospace, automotive manufacturing, and toolmaking. The electronic lead screw system it features allows machinists to achieve highly accurate cuts, while the heavy cast iron bed ensures consistent stability. Educational institutions have also adopted this model, making it a valuable training tool for future machinists.

However, the 10EE does require careful maintenance and a proper setup to operate at peak performance. It is also more expensive than simpler manual lathes, making it better suited for users who understand the value of long-term investment in precision equipment.

Modern CNC Monarch

As industries embraced digital automation, Monarch responded with CNC-controlled lathes. These machines allow machinists to program complex operations, reducing human error and significantly increasing productivity. CNC Monarch machine are particularly suited to mass production environments where repeatability is essential. While they are more costly and require programming expertise, they remain indispensable in modern factories that prioritize precision and efficiency.

Other Notable Models

Beyond the 10EE and CNC versions, Monarch also developed larger and more specialized machines. The 12EE and 16EE models were built for handling larger components, serving industries that needed to machine oversized parts. For smaller workshops and hobbyists, Monarch produced toolroom lathes that retained the brand’s precision but in a more accessible form.

Vintage models, particularly the 10EE, remain highly sought after by collectors. Many of these machines have been modernized with digital readouts, upgraded spindle systems, and stepper motors, bridging the gap between traditional craftsmanship and modern expectations.

Buying Considerations

Investing in a Monarch lathe requires careful planning and informed decision-making. Buyers must first decide whether they prefer a new machine or a vintage model. New units come with the advantage of warranty coverage, technical support, and the latest engineering upgrades. In contrast, vintage models can be more affordable and collectible, but they may require refurbishment or careful inspection to confirm performance.

Condition is a critical factor when evaluating a used machine. Inspecting the spindle for wear, ensuring bed alignment, and checking the integrity of all moving parts is essential before making a purchase. Many machinists recommend requesting service records or even arranging an in-person demonstration to ensure the lathe meets expectations.

Budget also plays a key role. Prices typically range from $5,000 to over $50,000, depending on age, condition, and included features. Buyers must also factor in transportation and installation costs, as these machines are extremely heavy and require a level, reinforced surface for proper operation.

Sourcing these machines can be done through industrial equipment dealers, online auctions, or collector forums. Checking seller reputations and reading customer reviews is crucial. In many cases, hobbyists and professionals alike emphasize the importance of verifying every detail before committing to a purchase. For additional reference, sites like Practical Machinist often provide useful insights from machinists who have first-hand experience with Monarch equipment.

Maintenance and Care

Maintaining a precision lathe is essential for extending its lifespan and ensuring consistent accuracy. Daily upkeep should involve removing chips and debris, applying lubrication to moving parts, and inspecting for any signs of wear or misalignment. Over time, bearings, tailstock alignment, and feed systems may need attention.

CNC-controlled models introduce additional responsibilities. Operators must regularly check electrical connections, ensure software updates are current, and perform calibration tests. This attention to detail ensures the machine’s performance remains accurate over time. Vintage machines, meanwhile, benefit from periodic professional servicing, which may involve replacing worn components with modern equivalents.

Storage conditions are another factor in long-term care. Keeping the lathe in a clean, dry, and temperature-controlled environment prevents corrosion and unnecessary mechanical wear. Some collectors also choose to upgrade their vintage lathes with high-quality replacement parts, further extending their usefulness and precision.

Applications

The applications of a Monarch machine span across multiple industries. Their ability to achieve exacting tolerances makes them indispensable for aerospace manufacturing, where even the smallest error can compromise the integrity of a component. Automotive companies depend on them to produce precise engine and transmission parts, while specialized toolmakers rely on these machines to craft custom instruments where uniformity and accuracy are essential.

Educational institutions also integrate Monarch machines into their machining programs. By training students on this equipment, schools ensure that future professionals develop the technical skills, patience, and discipline required to succeed in manufacturing and engineering. The opportunity to work with such high-precision tools gives students a head start in industries where precision is a non-negotiable standard.

Collectors and hobbyists make up another significant group of users. Many vintage 10EE models are carefully restored and placed in personal workshops, where they are used for small-scale projects ranging from woodworking accessories to custom metal parts. One striking example is a machinist who brought a 1950s 10EE back to life and used it to produce high-tolerance components for both wood and metal applications.

Conclusion

The Monarch lathe is more than a machine; it is a symbol of engineering heritage and unmatched precision. For over a century, these lathes have earned trust across industries, including aerospace, automotive, education, and small-scale workshops. Whether it is the legendary 10EE or modern CNC models, they are valued for delivering reliability, accuracy, and versatility. Collectors, educators, and professionals continue to appreciate their lasting performance and adaptability, making Monarch a cornerstone in precision machining.

When purchasing one of these lathes, it is important to understand its history, evaluate models, and carefully consider condition and budget. With proper care and maintenance, these machines can remain effective for decades, proving to be a lasting investment. Embracing both the tradition and innovation of the brand allows machinists to benefit fully from its capabilities. Exploring additional guides on machining and equipment ownership can further enhance skill and experience with these legendary tools.

Frequently Asked Questions

Is a Monarch machine suitable for beginners?

Some models are accessible to beginners, particularly smaller manual lathes, but most require a basic understanding of machining principles. CNC models, in particular, demand knowledge of programming.

What is the difference between the 10EE and CNC models?

The 10EE is a manual precision lathe known for accuracy, while CNC models offer programmability and automation for industrial-scale production. Both uphold Monarch’s reputation for precision.

How long do Monarch 10EE lathes last with proper maintenance?

With consistent care, these lathes can last for decades. Many 10EE models from the mid-20th century still function reliably today.

Is it possible to upgrade older precision lathes with modern technology?

Yes. Many machinists retrofit them with digital readouts, updated spindles, and stepper motors to combine vintage durability with modern precision.

Where can replacement parts be purchased?

Replacement parts are available through official distributors, specialized industrial equipment suppliers, and online machinist forums where collectors and professionals exchange resources.