A portable lathe is an essential tool for both hobbyists and professional craftsmen in woodworking and metalworking. Its mobility and versatility make it invaluable for a wide range of applications, from shaping intricate wood designs to machining metal components on-site. Unlike traditional lathes that are stationary, it provides the freedom to move the machine to the workpiece, allowing users to perform precision tasks even in confined spaces or temporary work areas.

This guide explores everything you need to know about this machine, including its types, essential features, safe usage practices, maintenance tips, and buying advice to help you make informed decisions and get the most out of this versatile tool.

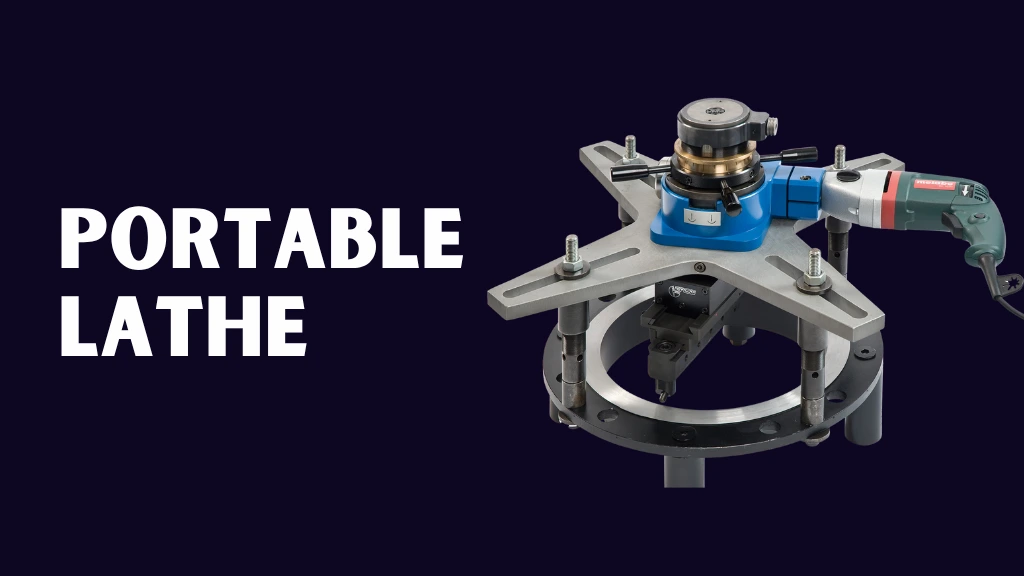

What Is a Portable Lathe?

A portable lathe designed to perform turning operations directly at the job site or in limited-space workshops allows machinists and woodworkers to take the machine to the material, saving time and reducing the need to transport large workpieces. These machines can handle a variety of materials, including wood, metal, and plastics, depending on the model, making them a versatile addition to any workspace.

These machines are commonly used in small workshops, construction sites, furniture manufacturing, and repair tasks, offering flexibility that stationary lathes cannot provide. By bringing the machine to the workpiece, users can complete precision operations more efficiently, which is especially useful for large or heavy components. The ability to work on-site reduces downtime and enhances overall productivity for both hobbyists and professionals.

One of the most significant benefits of this equipment is its versatility. It can handle simple tasks, such as turning a wooden spindle or shaping a pen, as well as more demanding operations like machining metal shafts or creating detailed decorative pieces. Modern models are equipped with variable speed settings, tool rests, and precision components, ensuring accurate results. Whether you are a beginner or a professional, a portable machine can greatly enhance the efficiency and quality of your work.

Advantages of a Portable Machine

The primary advantage of this equipment is its mobility. Unlike a fixed lathe, which requires a dedicated workshop space, it can be moved to different job sites or work areas. This mobility is particularly beneficial for repair work, on-site machining, or woodworking projects in temporary locations, allowing users to work efficiently without relocating large components.

The space-saving design also makes it ideal for small workshops or home garages where floor space is limited. Despite its compact size, this type of machine offers versatility, handling a variety of materials including wood, metal, and composites. Users can complete a wide range of projects without the need for multiple machines, making it a practical addition to any workspace.

Another notable benefit is cost efficiency. A portable small lathe is generally more affordable than full-size workshop machines, making it accessible to hobbyists and small business owners alike. These machines often have simpler setups, reducing preparation time and improving overall productivity. By combining mobility, versatility, and affordability, this equipment provides a practical solution for modern workshops and on-site machining operations.

Types of Portable Mobile Lathe

A portable lathe is available in several configurations to meet the specific needs of woodworkers and machinists. One common type is the mini wood lathe, which is compact, lightweight, and designed for small-scale woodworking projects. These smaller machines are ideal for turning spindles, small bowls, pens, and decorative wooden pieces. Mini wood lathes often include adjustable speed settings and tool rests, allowing users to achieve precise cuts and smooth finishes.

Another category is the metal version, built to handle metal parts with higher precision. These machines are generally heavier and more robust than wood lathes, offering durability and stability when machining metal shafts, rods, or small components. They are often used in repair shops, industrial maintenance, or small-scale manufacturing where portability is important.

A third type, combination machines, provides versatility for users who work with both wood and metal. These typically have interchangeable components and adaptable speed controls, allowing users to switch between materials without investing in multiple devices. For workshops with diverse project requirements, these machines offer the flexibility to perform both decorative woodworking and precise metal machining within a single tool.

Essential Features to Consider

When selecting a portable mobile lathe, several features are critical to ensuring performance, durability, and suitability for your projects. Motor power is one of the most important factors, as it determines the machine’s ability to cut through different materials. Smaller wood lathes may operate with motors ranging from half a horsepower to one horsepower, while metal lathes generally require higher power to handle dense materials effectively. Evaluating motor strength according to your project needs ensures smooth and reliable operation.

Speed settings also play a crucial role in versatility. Variable speed controls allow users to adjust the machine’s rotation according to the material and cutting technique, which helps achieve smooth finishes and reduces the risk of errors. Swing over the bed, which refers to the maximum diameter a workpiece can have while being turned, is another important consideration. Additionally, the distance between centers determines the maximum length of the workpiece that the lathe can accommodate, so it is essential to match these specifications to your typical projects.

Other features, such as a proper tool rest, ensure stability and precision during turning operations, while high-quality construction in steel or cast iron improves longevity and minimizes vibrations. Portability aspects, including handles or lightweight frames, make transporting the lathe easier and enhance usability for on-site projects. By carefully considering these factors, users can select a machine that is both reliable and versatile, meeting the demands of a wide range of woodworking and metalworking tasks.

Safety Precautions

Operating this type of lathe requires strict adherence to safety protocols. Safety goggles and hearing protection are essential to prevent injuries from flying debris and noise. Workpieces must be secured firmly before starting the machine to avoid accidents caused by loose materials. Clothing and jewelry should be kept away from moving parts, and the workspace should remain clear of obstructions.

Regular inspection of belts, screws, and moving components ensures the machine operates safely and efficiently. Following the manufacturer’s instructions for operation, maintenance, and accessories is vital to prevent accidents and prolong the equipment’s life. Beginners should familiarize themselves with the operation through tutorials or supervised training before attempting complex tasks. By practicing proper handling and setup, users can minimize risks and achieve high-quality results.

Maintenance Tips for Longevity

Maintaining a portable compact lathe is essential for consistent performance and safety. After each session, clean the machine thoroughly to remove dust, chips, and debris. Lubricating moving parts, as recommended by the manufacturer, reduces friction and prevents premature wear. Inspecting screws, bolts, belts, and gears ensures that all components remain tight and functional.

Any worn or damaged parts should be replaced immediately to prevent further issues. Storing the machine in a dry, clean environment protects it from moisture and dust, reducing the risk of corrosion and mechanical failure. Regular maintenance not only extends the equipment’s lifespan but also enhances precision and user confidence, ensuring reliable operation over time.

Accessories to Enhance Functionality

A compact lathe becomes even more versatile with the right accessories. Chisels and gouges are essential for detailed shaping and carving, while faceplates and chucks hold workpieces securely during turning operations. Tool rests improve control and stability for intricate or prolonged cuts, making precision work easier and more consistent.

Digital calipers help achieve accurate measurements, which is crucial for professional-quality results. Live centers provide support at both ends of long workpieces, reducing vibration and improving surface finish. Investing in high-quality accessories ensures the lathe can handle a wide range of tasks efficiently. This improves workflow, precision, and overall project outcomes for both woodworking and metalworking applications.

Real-World Application

Consider a small woodworking shop that integrated a portable handheld lathe into their operations. Previously, projects required moving large wooden components to a stationary lathe, which was time-consuming and limited workflow flexibility. With the addition of this machine, the team could perform on-site turning and machining, dramatically improving productivity.

By using this type of lathe, the workshop was able to expand service offerings, handle more diverse projects, and complete tasks more efficiently. This improvement in workflow ultimately increased customer satisfaction and helped boost overall revenue, demonstrating the practical benefits of incorporating mobile equipment into a small-scale operation.

Buying Guide

Selecting the right portable lathe involves evaluating several important factors. Start by considering the intended use of the machine, whether for wood, metal, or both. Establishing a budget is essential to ensure the lathe meets project requirements without overspending. Size and weight should also be assessed, making sure it fits the available workspace and can be transported if needed.

Brand reputation and customer reviews provide valuable insight into quality, reliability, and long-term performance. Choosing a machine from a trusted manufacturer ensures support, availability of parts, and overall satisfaction with your investment. By carefully considering these factors, users can select a lathe that maximizes efficiency and productivity for their specific projects.

Conclusion

A portable lathe is a versatile and efficient tool for modern woodworking and metalworking, offering mobility, functionality, and precision for both hobbyists and professional craftsmen. Understanding the different types, essential features, and proper maintenance helps users maximize its benefits and achieve professional-quality results. Choosing a reliable model from a trusted brand ensures durability and consistent performance. Whether for home projects, on-site work, or professional production, this machine expands capabilities, enhances efficiency, and becomes a valuable addition to any workshop or job site.

Frequently Asked Questions

What materials can a portable small lathe handle?

These lathes are capable of handling a variety of materials including wood, metals, plastics, and composites. The specific capabilities depend on the lathe’s construction, motor power, and accessories used. Selecting the right lathe for your primary materials is key to achieving optimal results.

Is a portable compact lathe suitable for beginners?

Yes, many portable compact lathes are designed with user-friendly features, making them suitable for beginners. Proper training and adherence to safety practices are essential to ensure successful and safe operation.

How much does a portable machine cost?

The price of a portable machine lathe varies depending on its size, features, and brand. Basic models for woodturning may start around a few hundred dollars, while high-performance metal lathes can reach several thousand dollars. Evaluating your project needs will help determine the appropriate investment.

Can a portable mobile lathe be used for professional work?

Absolutely. Many professionals rely on portable mobile lathes for on-site machining, custom furniture production, and maintenance tasks. With the right accessories and proper setup, this type of lathe can meet professional standards and improve workflow efficiency.