Precision turning is one of the cornerstones of modern machining. Whether you are shaping metal, wood, or composites, achieving smooth and consistent curves can be challenging without the right tools. A radius cutter for lathe is designed specifically for this purpose. It allows machinists to cut arcs, radii, and spherical shapes with a level of accuracy that is nearly impossible to achieve by hand.

In this comprehensive guide, we will explore what a radius cutter is, how it works, the different types available, how to set one up, and why it is such an essential tool in workshops. Whether you are a professional machinist, a hobbyist, or a DIY enthusiast, this article will give you everything you need to know about radius cutters for lathes.

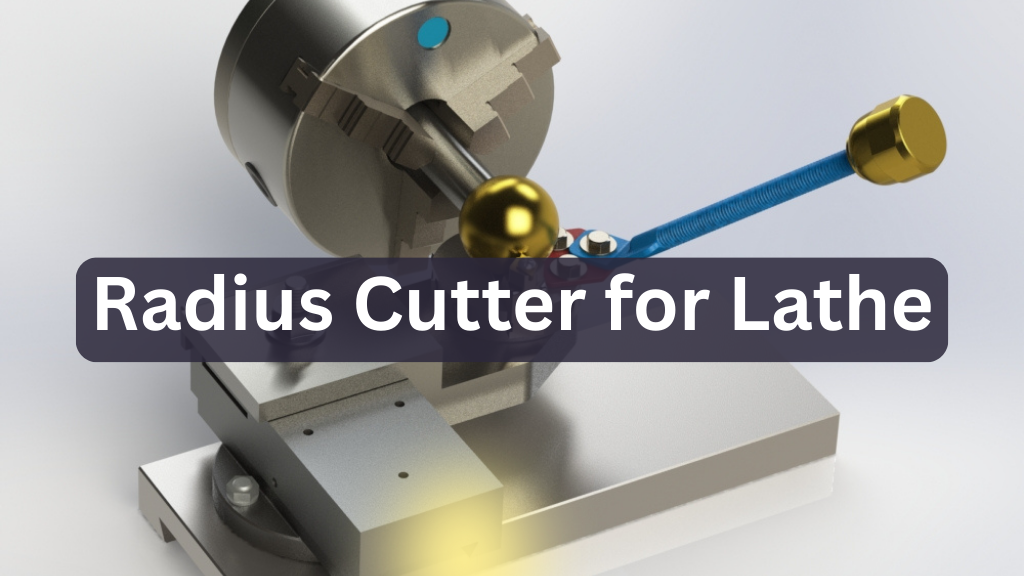

What Is a Radius Cutter for Lathe?

A radius cutter for lathe is a tool used to cut spherical or rounded surfaces on a workpiece. It works by pivoting a cutting tool around a fixed point, which creates smooth arcs and curves.

Unlike traditional turning tools that move linearly, a radius cutter moves along a circular path, ensuring a consistent and precise radius every time. This makes it particularly useful for:

- Ball turning

- Convex and concave surfaces

- Decorative machining

- Spherical ends on shafts and rods

- Knobs, handles, and ornamental designs

By using a radius cutter, machinists can reduce manual error and speed up production, all while maintaining a professional finish.

Why Use a Radius Cutter for Lathe?

Turning tools are excellent for producing cylindrical parts, but they struggle when it comes to creating curves or spherical shapes. A radius cutter solves this problem by introducing pivot-based cutting.

Key Benefits of Radius Cutters:

- Accuracy: Ensures consistent radii, essential for repeat production.

- Efficiency: Cuts curves faster than manual shaping.

- Versatility: Works on both convex and concave surfaces.

- Professional Finish: Delivers smooth, aesthetic results.

- Durability: Suitable for different materials including metals, plastics, and wood.

For anyone who needs to create rounded components regularly, a radius cutter is not just helpful, it is necessary.

Types of Radius Cutters for Lathes

Not all projects require the same tool. Different types of radius cutters are available, each designed for specific applications.

Fixed Radius Cutters

- Designed for a single radius size.

- Ideal for mass production where one radius is repeatedly needed.

- Extremely durable and precise but limited in flexibility.

Adjustable Radius Cutters

- Can be adjusted to cut different radius sizes.

- Perfect for machinists who work on a wide range of projects.

- Offers more versatility than fixed cutters.

Convex Lathe Radius Cutter

- Specially designed to cut outward curved surfaces.

- Essential for producing spherical shapes, domes, and rounded ends.

Ball and Radius Turning Tool

- A combination tool designed for cutting both full and partial spheres.

- Commonly used for producing knobs, handles, and ball joints.

DIY Radius Cutter for Lathe

- Built by machinists who prefer custom setups.

- More affordable than commercial tools but requires skill to construct.

- Great option for hobbyists and small workshops.

Choosing the Best Radius Cutter for Lathe

Selecting the right radius cutter for your lathe is important for achieving accurate curves and smooth finishes. The ideal cutter depends on your machine type, the materials you work with, and the precision required for your projects. A poorly matched cutter can result in inconsistent results or faster tool wear. By considering key factors, you can choose a tool that enhances both efficiency and quality.

-

Lathe Compatibility

The first step in choosing a radius cutter is checking compatibility with your lathe. The cutter must fit your tool post and match the swing capacity of your machine. Using an oversized or undersized cutter can lead to poor performance or even damage to the lathe. Always verify the specifications before making a purchase. Compatibility ensures safe and reliable operation.

-

Radius Range

Different cutters offer varying radius capabilities, from fixed sizes to adjustable models. Fixed radius cutters are useful for repetitive tasks where the same curve is needed. Adjustable cutters, however, provide more flexibility for different projects. Professionals often prefer adjustable designs because they save time and reduce the need for multiple tools. The choice depends on whether you value convenience or specialization.

-

Build Quality

The durability of a radius cutter largely depends on its build quality. Hardened steel with precision machining ensures longer tool life and better accuracy. Inferior materials can wear quickly, reducing cutting efficiency and increasing replacement costs. A well-built cutter not only performs better but also withstands heavy-duty use. Investing in quality pays off in the long run.

-

Ease of Use

Some cutters are easier to set up and calibrate than others. For beginners or hobbyists, a straightforward design reduces setup time and frustration. Professional machinists may prefer more advanced models with fine adjustment features. The ease of changing inserts and aligning the tool also plays a role. A user-friendly cutter increases productivity and reduces errors.

-

Cutting Tool Options

Radius cutters may use different cutting tools such as carbide inserts or high-speed steel bits. Carbide inserts are durable and excellent for hard materials, while high-speed steel is more affordable and easier to sharpen. Some cutters allow interchangeable inserts, giving more flexibility. Choosing the right cutting option depends on your workload and the materials you frequently machine. Flexibility adds value to the tool.

-

Price

Price is always an important factor, but it should be weighed against performance and durability. Professional machinists may justify investing in higher-quality adjustable cutters. Hobbyists, on the other hand, may prefer budget-friendly or even DIY options. Used cutters can also be a cost-effective choice if they are in good condition. Balancing cost with functionality ensures the best value.

-

Final Recommendation

For professionals, a high-quality adjustable radius cutter is often the best choice since it offers flexibility and durability. Hobbyists or occasional users may find DIY tools or used cutters more practical. The decision ultimately depends on your machining requirements, budget, and long-term goals. Choosing wisely will enhance both precision and efficiency in your work.

How to Set Up and Use a Radius Cutter

Proper setup of a radius cutter is essential for achieving accurate and smooth curves on a lathe. Even a small misalignment can result in poor finishes or inaccurate dimensions. By following a step-by-step approach, machinists can ensure precision while also extending the life of their tools. Below are the key steps involved in setting up and using a radius cutter effectively.

-

Mount the Cutter

Begin by securely fixing the radius cutter to the lathe’s tool post. Make sure it is locked firmly in place to prevent vibration during cutting. A loose setup can cause chatter and lead to poor surface finishes. Correct mounting also helps maintain consistent accuracy throughout the operation. Stability at this stage is the foundation of precision machining.

-

Align the Pivot Point

Next, align the pivot point of the cutter so it matches the axis of the workpiece. This step ensures that the cutter sweeps evenly across the material while forming the curve. Misalignment can distort the radius and result in uneven cuts. Many machinists use a test cut or gauge to confirm proper alignment. Accurate setup here prevents rework later.

-

Adjust the Radius

Set the arm length of the cutter to achieve the desired radius for your project. Fixed-radius cutters require no adjustment, while adjustable cutters offer more flexibility. Double-check the measurements before cutting to avoid errors. Small changes in arm length can make a big difference in the final shape. Precision in this step is critical for achieving the correct dimensions.

-

Insert the Tool Bit

Install a sharp tool bit, typically made of high-speed steel or carbide. Carbide inserts are durable and ideal for hard materials, while high-speed steel is easier to sharpen. Ensure the bit is seated firmly in the cutter. A sharp tool minimizes cutting resistance and produces a smoother surface finish. Tool quality directly affects both performance and accuracy.

-

Set Lathe Speed

Adjust the spindle speed and feed rate according to the material being machined. Harder materials require slower speeds, while softer ones can be cut at higher speeds. Correct speed and feed settings reduce tool wear and improve efficiency. Following recommended cutting data for the material ensures optimal results. Proper speed adjustment also minimizes heat buildup during cutting.

-

Start Cutting

Once everything is set, begin the cutting process by slowly pivoting the cutter around the radius axis. Take steady, controlled movements to avoid sudden pressure on the tool. Always start with light cuts instead of deep passes. This reduces strain on both the cutter and the workpiece. A gradual approach helps achieve cleaner and more accurate results.

-

Inspect the Cut

After cutting, inspect the workpiece using calipers or a radius gauge to verify dimensions. Measuring ensures that the final shape matches the required specifications. If adjustments are needed, make small corrections and repeat the cutting process. Regular inspection throughout production helps maintain consistency. This step is crucial for quality control in machining.

For the best results, always take light cuts instead of deep ones. Shallow passes produce smoother finishes and extend the life of the cutting tool. They also reduce the chance of damaging the workpiece or the cutter. Patience during this process pays off with higher accuracy and cleaner results. Professional machinists often prioritize quality over speed.

DIY Radius Cutter for Lathe

Many machinists build their own DIY radius cutter for lathe. A homemade tool can be just as effective as a commercial one if built correctly.

Materials You’ll Need:

- Steel flat bar or square stock

- Pivot pin or bolt

- Tool holder clamp

- Fasteners and washers

- Cutting tool slot

Basic Steps:

- Cut the steel bar to the required length.

- Drill a pivot hole for rotation.

- Machine a slot for the tool bit.

- Install the pivot pin for free movement.

- Secure the cutter to your lathe’s tool post.

Although less refined than factory-made models, a DIY radius cutter is cost-effective and customizable.

Real-World Applications of Radius Cutters

Radius cutters are not just for hobbyists. They play a vital role in multiple industries:

- Automotive: Creating ball joints, bearings, and rounded engine components.

- Aerospace: Precision spherical parts used in navigation systems.

- Woodturning: Decorative bowls, knobs, and handles.

- Metal Fabrication: Custom machine parts requiring rounded edges.

- Hobby Machining: Model making and custom DIY projects.

Their versatility ensures they remain one of the most valuable tools in a machinist’s collection.

Buying a Used Radius Cutter for Lathe

If you are on a budget, purchasing a used radius cutter for lathe can be a smart option. However, keep the following in mind:

- Inspect the pivot point for excessive wear.

- Ensure the tool holder still clamps securely.

- Check if replacement parts or inserts are available.

- Compare the cost savings against potential repairs.

Used cutters are excellent for hobbyists but professionals may prefer new ones to guarantee accuracy and durability.

Radius Cutting Tool Bits

The tool bit is what actually cuts the material, and choosing the right one is critical.

Options Include:

- High-Speed Steel (HSS): Affordable, easy to sharpen, suitable for softer metals.

- Carbide Inserts: Durable, long-lasting, excellent for hard metals.

- Diamond Tools: Used in ultra-precision applications.

For most applications, carbide inserts are considered the best choice due to their balance of durability and precision.

Maintenance of Radius Cutters

Proper care ensures your radius cutter lasts for years.

- Keep the pivot well lubricated.

- Clean the cutter after each use.

- Store in a dry place to prevent rust.

- Replace dull or chipped inserts immediately.

- Regularly calibrate to ensure cutting accuracy.

By following these practices, you can extend the lifespan of your tool and maintain consistent performance.

Conclusion

A radius cutter for lathe is an indispensable tool for anyone involved in precision machining. From creating decorative knobs to manufacturing aerospace components, it offers versatility, accuracy, and efficiency. Whether you choose a professional-grade adjustable tool, a used radius cutter, or a DIY solution, this tool will significantly enhance the capabilities of your lathe.

By selecting the right ball and radius turning tool and maintaining it properly, you can achieve professional-quality results across countless projects. For hobbyists, it opens new creative possibilities, and for professionals, it ensures consistent and high-quality production.

Investing in a reliable radius cutter is not just about convenience. It is about achieving precision, saving time, and expanding what your lathe can do.

FAQs

What is a radius cutter for lathe used for?

It is used to cut spherical shapes, arcs, and radii on a workpiece with precision.

Can I build a DIY radius cutter?

Yes, many machinists create DIY versions using steel stock and pivot systems.

What is the difference between convex and concave cutting?

Convex cutting produces outward curves while concave cutting creates inward arcs.

Are used radius cutter for lathe worth it?

Yes, as long as they are in good condition. However, always check for wear and tear before buying.

What is the best radius cutter for small lathes?

An adjustable ball and radius turning tool is ideal for small to medium lathes because it offers flexibility.

Can radius cutters be used for wood?

Yes, although they are primarily designed for metal, they can also be used in woodturning applications.

How do I measure the radius accurately?

Use radius gauges, calipers, or templates to confirm the correct size during and after machining.