The rose engine lathe is a fascinating and highly specialized form of ornamental turning equipment that has captured the interest of watchmakers, jewelers, and decorative artisans for more than two centuries. Known for producing intricate, repetitive patterns on metal, wood, and other materials, it remains a symbol of precision engineering and craftsmanship. In the world of horology and fine decorative arts, the rose engine lathe is not only a tool but a heritage instrument that connects the modern maker to the artisans of the past.

In this article, we will explore what a rose engine lathe is, how it works, its historical significance, design variations, and its use in both traditional and modern industries. We will also look at how it continues to find relevance in the twenty-first century, especially in the United States and other Western countries where both historical restoration and modern artisanal work thrive.

What is a Rose Engine Lathe?

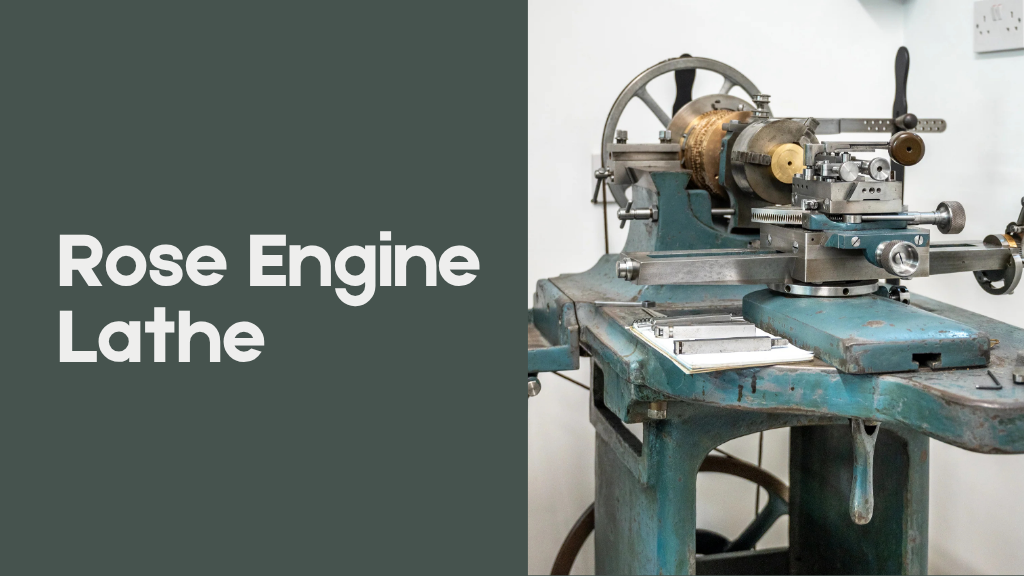

A rose engine lathe is a type of ornamental lathe specifically designed to create detailed and often symmetrical patterns on cylindrical or flat surfaces. These patterns, sometimes referred to as guilloché, are achieved by controlling the movement of the workpiece using specially shaped rosettes or cams. The patterns are both decorative and functional, as they can enhance grip or reflect light in intricate ways.

The defining feature of the rose engine lathe is its ability to move the workpiece in multiple directions relative to the cutting tool. Unlike standard lathes, which typically rotate the workpiece in a fixed position, the rose engine can rock, slide, and oscillate the piece to create complex designs.

Historical Background

The origins of the rose engine lathe trace back to the late 17th and early 18th centuries in Europe. The device gained prominence during the Georgian and Victorian periods, where it was used extensively in decorative arts, especially in luxury items such as watch dials, snuff boxes, and royal insignia.

Royal courts and wealthy patrons commissioned master craftsmen to produce works using these lathes. European monarchs, including members of the Russian and British royal families, were known collectors of objects featuring guilloché patterns. The intricate nature of the designs produced by rose engine lathes made them a mark of prestige and technical mastery.

In the United States, rose engine lathes became known in the 19th century through imported machines from England and continental Europe. American watchmakers and engravers began adapting the technology for their own decorative work.

How a Rose Engine Lathe Works

A rose engine lathe operates through a unique blend of rotational and oscillating movements, allowing artisans to carve complex, repeating patterns with precision. At its heart is a set of rosettes, which are specialized cam-like discs mounted on the spindle. As the workpiece rotates, these rosettes press against a fixed follower that guides the movement of the headstock or the workpiece itself. This precise motion reproduces the rosette’s shape in the material, creating intricate and symmetrical designs.

-

Rosettes: The Pattern Templates

Rosettes serve as the guiding patterns for the decorative work. Each rosette has a unique profile that directly determines the design produced on the workpiece. Swapping or combining rosettes allows for an endless variety of patterns.

-

Follower: Tracking the Design

The follower is a lever or roller that physically traces the contour of the rosette. This movement translates into the oscillation needed to cut the repeating patterns accurately.

-

Slide Rest: Positioning the Cutting Tool

The slide rest holds and precisely moves the cutting tool. Operators can adjust it in multiple directions to control the depth and position of the cut.

-

Cutting Tool: Crafting the Design

A graver or small rotary cutter is commonly used as the cutting tool. It removes material to reveal the decorative pattern, and the choice of tool affects the texture, depth, and finish of the final design.

-

Indexing Mechanism: Dividing the Workpiece

This mechanism allows the operator to divide the workpiece into evenly spaced segments. It ensures that designs remain perfectly symmetrical across the surface.

-

Drives and Belts: Powering the Lathe

The drives and belts power both the rotation of the spindle and the oscillating motion required for pattern creation. This ensures smooth and consistent operation.

By experimenting with different rosettes, follower positions, and cutting depths, skilled operators can produce thousands of unique designs that range from simple geometric lines to elaborate floral motifs.

Applications in Horology

One of the most famous uses of the rose engine lathe is in the field of watchmaking. Guilloché patterns on watch dials not only enhance beauty but also serve functional purposes such as reducing glare or providing a textured surface that makes the dial easier to read.

High-end watch brands in Switzerland, Germany, and the United States still employ rose engine lathes to produce handcrafted dials. Each dial can take several hours to complete, and the process requires exceptional skill. This traditional method remains valued even in the era of CNC machining, as it provides a unique tactile quality that cannot be perfectly replicated by automated processes.

Artistic and Decorative Uses

Rose engine lathes are not limited to watchmaking; their ability to create intricate and precise patterns makes them a valuable tool for various artistic fields. These machines enable artisans to blend geometry and creativity, resulting in visually stunning, historically authentic works.

-

Jewelry Making

Artisans use rose engine lathes to craft delicate textures and ornamental patterns on rings, bracelets, pendants, and other fine jewelry. The precision allows for unique designs that stand out in both modern and vintage-inspired pieces.

-

Woodturning

In woodworking, rose engine lathes add ornate patterns to bowls, boxes, furniture components, and other decorative wooden objects. This technique elevates everyday items into pieces of art.

-

Metal Engraving

The machines are often used to engrave intricate designs on silverware, presentation plates, luxury watches, and even custom firearms, adding a sense of craftsmanship and exclusivity.

-

Fine Art Restoration

Museums and collectors rely on rose engine lathes to reproduce historical designs with accuracy. This ensures that restored items maintain their original beauty and authenticity.

Modern-Day Relevance

Although many rose engine lathes built in the 19th century are now museum pieces or collector’s items, modern craftsmen continue to build and use them. In the United States, small workshops produce contemporary versions of these machines using updated materials and precision engineering techniques.

Custom-built rose engine lathes are sought after by professional engravers, luxury watch brands, and high-end woodworkers. Online communities, social media groups, and specialist guilds share patterns, restoration tips, and video demonstrations to keep the tradition alive.

Collecting and Restoring Rose Engine Lathes

Vintage rose engine lathes are prized collectibles. Restoring one involves careful cleaning, mechanical adjustments, and sometimes machining replacement parts. Many antique models were custom-made for specific artisans, so no two are exactly alike.

Collectors in the USA, UK, and Europe often seek out models from renowned makers like Holtzapffel, Plant, or Evans. Auctions, estate sales, and specialized dealers remain key sources for these machines.

Building Your Own Rose Engine Lathe

For those with machining skills, building a rose engine lathe from scratch or from plans can be a rewarding project. While it requires precision and patience, the ability to create custom rosettes and unique patterns offers creative freedom not easily matched by other tools.

Key considerations when building a rose engine lathe include:

- Material selection for frame and moving parts

- Precision alignment of spindle and slide rest

- Designing and cutting rosettes

- Incorporating adjustable followers for pattern versatility

Learning to Use a Rose Engine Lathe

Mastering a rose engine lathe involves understanding both mechanical operation and artistic design. Beginners often start with simple rosettes to learn how different patterns are generated. Over time, they develop skills to blend multiple rosette patterns, adjust cutting depth, and experiment with various materials.

Workshops and courses are available in the USA and Europe for those interested in hands-on training. Many experienced artisans are willing to mentor newcomers, ensuring that this specialized craft is passed on to future generations.

Where to See a Rose Engine Lathe in Action

Several museums and horology institutes display operational rose engine lathes. The American Watchmakers-Clockmakers Institute and the British Museum both feature these machines in their exhibits. Demonstrations are also common at woodturning and watchmaking conventions, where attendees can watch artisans produce guilloché patterns live.

Conclusion

The rose engine lathe stands as a testament to the enduring value of craftsmanship and mechanical ingenuity. From its royal European origins to its place in modern workshops, it continues to inspire artisans, collectors, and historians. While technology has evolved, the intricate beauty of guilloché patterns remains a timeless expression of skill. For anyone passionate about fine decorative work, learning or collecting rose engine lathes offers a direct link to centuries of artisanal tradition.

FAQs

What is the difference between a rose engine lathe and a regular lathe?

A regular lathe spins the workpiece around a fixed axis for shaping or cutting. A rose engine lathe moves the workpiece in controlled oscillations, guided by rosettes, to create decorative patterns.

Can a rose engine lathe be used for both metal and wood?

Yes, with the correct cutting tools and speeds, it can work on both materials. Historically, it has been used on metals like gold, silver, and brass, as well as fine hardwoods.

How much does a rose engine lathe cost?

Prices vary widely. Antique models can range from several thousand to tens of thousands of dollars, while modern replicas may be more affordable depending on features and craftsmanship.

Are rose engine lathes still used in manufacturing?

They are rare in mass production but remain popular in luxury goods, custom jewelry, and artisanal workshops.

Is it difficult to learn rose engine turning?

It requires patience and practice, but with proper instruction, most mechanically inclined individuals can learn the basics within a few weeks.