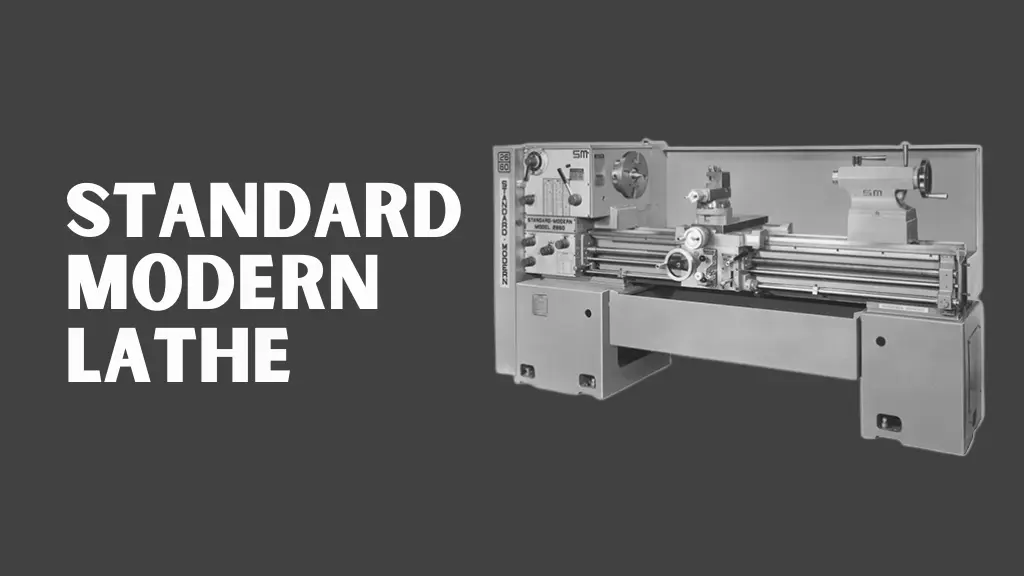

A Standard Modern Lathe is a cornerstone of precision machining, representing decades of engineering innovation and reliability. These lathes are widely recognized in professional workshops, educational institutions, and hobbyist environments for their ability to deliver consistent, high-quality results. Unlike older or generic lathes, Modern Lathes combine robust mechanical design with modern features that allow for a wide range of operations, including turning, threading, drilling, and facing. Understanding the features, applications, and maintenance requirements of these machines can significantly enhance the productivity and quality of any machining project.

Understanding the Standard Modern Lathe

The Standard Modern Lathe is built with high-quality materials and precise engineering that ensures long-term durability and stability during operation. The bed of the lathe, typically made from cast iron, provides a solid foundation, minimizing vibrations and improving accuracy during cutting. The spindle, housed in a rigid headstock, supports the rotation of the workpiece, allowing machinists to achieve precise cuts even with challenging materials. Many modern models include digital readouts and optional CNC compatibility, enabling users to automate complex machining tasks without compromising on accuracy. These features make it suitable for both manual and semi-automated operations, giving it an edge over older conventional machines.

Another defining characteristic is versatility. These Lathes can handle metals, plastics, and certain types of wood, depending on the tooling and setup used. This adaptability makes them invaluable in professional settings, from manufacturing precision parts in automotive and aerospace industries to creating prototypes in small workshops. The combination of precision, durability, and flexibility ensures these lathes can perform a wide range of tasks efficiently, which is why they are a staple in both educational and professional environments.

Key Features and Capabilities

One of the reasons machinists prefer Standard Modern Lathes is their extensive feature set. The headstock and spindle assembly are engineered for high rigidity, which ensures that the workpiece remains stable during high-speed operations. Precision bearings within the spindle reduce vibration, allowing for smooth rotation and improved surface finishes. The tailstock supports longer workpieces and allows for operations such as drilling and reaming, which adds to the machine’s adaptability.

The carriage and cross slide are designed to move smoothly along the lathe bed, allowing for accurate positioning of cutting tools and maintaining tight tolerances. The tool post holds cutting tools securely, reducing deflection during heavy-duty operations. Many modern lathes also incorporate variable speed control and digital readouts. Variable speed control allows operators to adjust spindle speeds depending on the material being machined, improving cutting efficiency and tool life. Digital readouts provide precise feedback on carriage and cross-slide positions, enabling extremely fine tolerances. Some models are CNC-ready, allowing automation for repetitive tasks and enhancing productivity.

Applications Across Industries

The versatility and precision of these lathes make them applicable across a wide range of industries. In educational settings, they serve as an excellent training platform for students learning machining techniques. Their robust design ensures safety and reliability, while their precision allows students to practice creating accurate parts without frustration. Using these lathes gives students hands-on experience with equipment similar to professional workshops.

In manufacturing, they are used to produce components that require high precision, such as automotive parts, aerospace components, and industrial machinery. The ability to handle various materials and perform multiple types of operations means that manufacturers can rely on a single machine for a broad range of tasks, improving productivity and reducing the need for multiple specialized machines.

Hobbyists and small workshop owners also benefit from their adaptability. Whether creating custom metal parts, wood components, or prototype pieces, these lathes offer the precision and stability required to achieve professional-quality results. Their combination of mechanical reliability and optional digital enhancements makes them practical for small-scale projects that demand accuracy.

Selecting the Right Machine

Choosing the right lathe requires careful consideration of several key factors. The material to be machined plays a critical role, as different lathe models are optimized for specific materials such as metals, plastics, or wood. Additionally, the size of the workpieces is an important consideration, with the maximum diameter and length determining which lathe can accommodate your projects efficiently.

Speed requirements also influence the decision-making process. Variable-speed lathes provide flexibility for different materials and operations, while fixed-speed models may be sufficient for more specialized tasks. Precision needs further guide whether a manual lathe or a CNC-ready model is the better option. Budget is an important consideration. Advanced models may cost more upfront. Their long-term durability and performance often justify the investment.

Examining real-world experiences and feedback from other machinists can significantly aid in making an informed decision. Online forums, product reviews, and case studies offer valuable insights into a machine’s reliability, maintenance needs, and practical challenges that may not be immediately apparent from specifications alone. Consulting these resources helps buyers select a lathe that aligns with their operational requirements and ensures optimal performance in the long term.

Maintenance for Longevity

Proper care is essential to maintain performance and extend the lifespan of these lathes. Daily cleaning removes chips and debris that could cause wear. Lubrication of moving parts reduces friction and prevents rust, while regular inspections help detect alignment issues, wear on belts or gears, and potential electrical concerns in CNC-equipped models.

Tool care is equally important. Keeping cutting tools sharp and properly mounted minimizes stress on the machine and ensures consistent results. Maintaining a clean, dry working environment helps prevent corrosion and preserves the integrity of mechanical and electronic components. Following a structured maintenance schedule ensures consistent accuracy and reliability over years of operation.

Industry Comparisons

Standard Modern Lathe machines are known for their sturdy construction. They deliver high precision. They stand out compared to other brands. Their rigid bed and robust spindle assembly provide stability during operations, which translates into more accurate and consistent results. Many competitors offer lower upfront prices. They often compromise bed rigidity and precision. Support services may also be limited, affecting long-term performance.

The optional inclusion of digital readouts and CNC compatibility further enhances the functionality of these lathes, allowing them to perform efficiently in both manual and automated workflows. These features provide machinists with greater control, improved accuracy, and the ability to handle complex or repetitive tasks with ease. Additionally, access to official resources and strong customer support ensures that users receive guidance for setup, routine maintenance, and troubleshooting whenever necessary.

Investing in a well-built lathe improves reliability, reduces downtime, and enhances the quality of output over time. While low-cost alternatives may seem appealing initially, they often require more frequent maintenance and may fail to deliver consistent precision. Careful evaluation of both performance characteristics and support infrastructure is essential to select a machine that meets operational demands and provides long-term value.

Conclusion

Investing in a Standard Modern Lathe provides machinists and workshop owners with a machine that combines precision engineering, versatile functionality, and long-term reliability. These lathes handle a wide range of materials. They perform many different operations. They are suitable for schools, professional workshops, and hobbyist projects. By delivering consistent accuracy and stable performance, they enable users to produce high-quality components while minimizing errors and material waste.

To fully leverage its capabilities, it is essential to make an informed selection based on intended use, material requirements, and precision needs. Routine maintenance, including lubrication, cleaning, and periodic inspections, ensures optimal performance and extends the machine’s lifespan. Understanding the features, operational limits, and proper handling techniques empowers users to achieve professional-level results, while maintaining safety and efficiency in the workshop.

FAQs

What materials can this lathe handle?

These lathes machine metals like steel, aluminum, and brass. They can also handle plastics. Certain types of wood can be machined depending on tooling and setup.

Is it suitable for beginners?

Yes, the lathe has a user-friendly design. Beginners can learn basic machining skills easily. Experienced users can access advanced features for more complex tasks.

How often should maintenance be performed?

Clean the lathe daily. Lubricate moving parts regularly. Inspect components periodically to maintain performance and accuracy.

Can it be upgraded to CNC?

Many models are CNC-ready, enabling users to add digital readouts or full CNC functionality for more automated operations.

Where can authentic machines be purchased?

Authorized distributors and the official company website are the most reliable sources, providing warranty support and technical guidance.