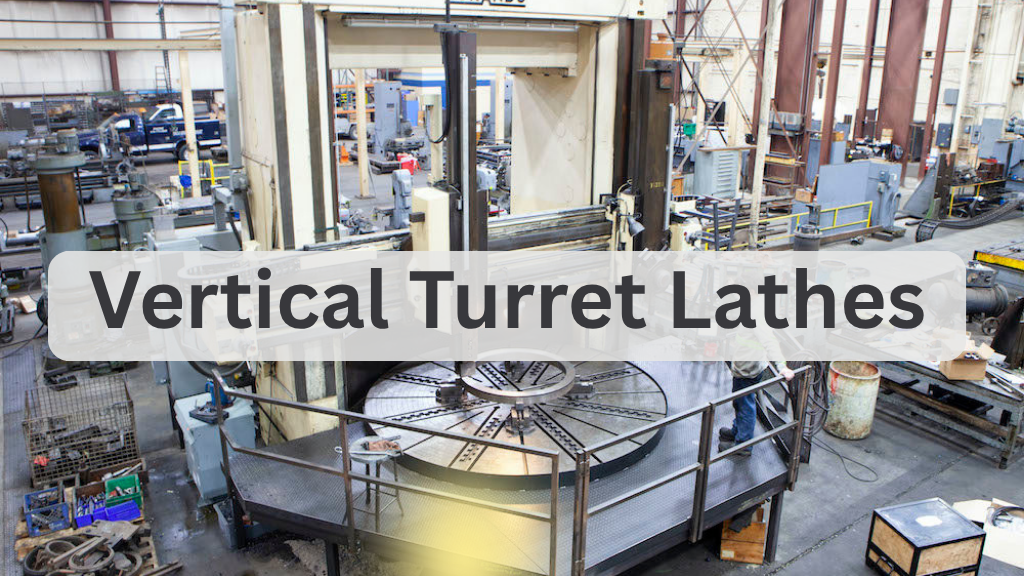

In the world of metalworking, precision and efficiency are key. For machinists, manufacturers, and engineers handling large, heavy, or unusually shaped workpieces, the vertical turret lathe (VTL) is a critical tool. Designed to machine oversized parts that are difficult to handle on horizontal lathes, a VTL offers stability, precision, and the ability to perform multiple machining operations without moving the workpiece.

Unlike traditional horizontal lathes, where the spindle is mounted parallel to the floor, a vertical turret lathe positions its work table and spindle vertically. This design allows the machine to support massive parts with gravity, reducing stress on the workpiece and the spindle bearings.

The vertical turret lathe has been a staple in manufacturing for decades, especially in industries such as aerospace, energy, automotive, and shipbuilding. Its combination of size capacity, accuracy, and versatility makes it one of the most valuable machines in heavy machining environments.

How a Vertical Turret Lathe Works

A vertical turret lathe is designed to handle large cylindrical parts by mounting them on a vertically oriented rotating table. The machine’s turret, which holds multiple cutting tools, can be moved both horizontally and vertically to perform different operations without having to stop and reset the workpiece.

Key Components of a VTL:

- Base: The foundation that supports the entire machine.

- Rotary Table: The large, flat surface that holds and spins the workpiece.

- Turret Head: Contains multiple tools for different machining operations.

- Cross Rail: A horizontal beam that moves up and down to adjust for workpiece height.

- Tool Slide: Allows tools to move towards or away from the center of the workpiece.

- Drive System: Powers the rotation of the table, usually through electric motors or hydraulics.

Machining Process:

- The workpiece is securely clamped onto the rotary table.

- The turret selects the appropriate cutting tool.

- The table spins, bringing the workpiece into contact with the cutting tool.

- The tool shapes, bores, faces, or drills as required.

- The turret rotates to switch tools for the next operation.

With modern CNC-controlled VTLs, the entire process can be programmed for automated operation, improving efficiency and consistency.

Key Features and Advantages

Vertical turret lathes (VTLs) offer distinct advantages over other machining methods, especially for processing large and heavy workpieces. Their design maximizes stability, precision, and efficiency in industrial applications.

-

Large Workpiece Capacity

VTLs can handle parts up to several meters in diameter, making them essential in industries such as aerospace, energy, and heavy equipment manufacturing. This capability allows for machining oversized components with ease.

-

Gravity Assistance

The vertical spindle design uses gravity to keep parts stable during machining. This reduces the need for complex fixturing and helps maintain consistent positioning for accurate results.

-

Multiple Operations in One Setup

With the ability to switch between tools for turning, boring, facing, and drilling, VTLs eliminate the need for re-clamping. This saves time, reduces handling errors, and improves workflow efficiency.

-

High Precision

VTLs offer reduced vibration and stable part positioning, leading to better machining accuracy. This is particularly important for heavy parts that require exact tolerances.

-

Space Efficiency

Although they handle large components, VTLs often occupy less floor space than equivalent horizontal machines. This makes them a practical choice for facilities with limited working area.

Types of Vertical Turret Lathes

While all vertical turret lathes share the same basic design, they vary in configuration, capacity, and control systems. Choosing the right type depends on the size of the workpiece, production volume, and required precision.

-

CNC Vertical Turret Lathes

CNC VTLs are computer-controlled machines that deliver exceptional precision and repeatability. They are ideal for producing complex shapes and are widely used in high-volume manufacturing environments.

-

Manual Vertical Turret Lathes

These machines are operated entirely by hand, giving machinists direct control over cutting operations. They are best suited for custom projects or small production runs where flexibility is needed.

-

Single-Column VTLs

Featuring one support column, these machines work well for smaller to medium-sized parts. Their design offers easier access to the workpiece while maintaining stability during machining.

-

Double-Column VTLs

Equipped with two support columns, these machines provide extra stability for very large and heavy workpieces. They are commonly used in heavy industries like shipbuilding and power generation.

-

Heavy-Duty vs Light-Duty

Heavy-duty VTLs are designed for cutting thick, high-strength materials such as steel or titanium. Light-duty versions are more suitable for softer metals like aluminum or copper.

Applications of Vertical Turret Lathes

Choosing the Right Vertical Turret Lathe

Maintenance and Best Practices

Cost Considerations

Vertical Turret Lathe vs Horizontal Turret Lathe

Choosing between a vertical turret lathe (VTL) and a horizontal turret lathe (HTL) depends on the size, shape, and material of the workpieces, as well as production requirements. Both have unique strengths suited for different applications.

Vertical Turret Lathe Advantages

- Better suited for large, heavy workpieces due to vertical orientation

- Gravity assists in keeping parts stable, making fixturing easier

- More compact footprint for heavy machining operations

Horizontal Turret Lathe Advantages

- Superior chip evacuation for certain materials, reducing downtime

- Faster cycle times when machining smaller parts, boosting productivity

Real-World Example

A Midwest turbine manufacturer replaced three older horizontal machines with a single CNC VTL. The result:

- Cycle Time Reduction: 35 percent faster production

- Setup Time Cut: From 4 hours to 45 minutes

- ROI: Achieved in under two years

Future Trends in Vertical Turret Lathes

The next generation of VTLs is embracing:

- IoT and Smart Machining: Real-time performance monitoring

- Energy Efficiency: Lower power consumption motors

- Hybrid Machines: Combining turning and milling capabilities

Conclusion

The vertical turret lathe is a cornerstone of heavy machining, offering unmatched capability for large, precise parts. Whether CNC-controlled or manual, single- or double-column, a well-chosen and maintained VTL can deliver decades of reliable service. For manufacturers aiming to improve production capacity, precision, and versatility, investing in a VTL is a proven strategy.

FAQs

What is the maximum size a VTL can handle?

Industrial VTLs can machine parts over 30 feet in diameter.

How does a turret differ from a regular tool holder?

A turret can hold multiple tools and rotate between them automatically.

Is CNC always better than manual for VTLs?

Not always. CNC is ideal for high-volume work, while manual machines suit custom, low-volume jobs.

How long does a VTL last with proper maintenance?

Many machines operate for 30 years or more when maintained properly.

Can a VTL replace other machine tools?

It can replace some horizontal lathes for large parts, but not milling machines or grinders.