In the intricate world of horology, the watchmaker lathe serves as an essential tool, allowing artisans to create components with exceptional accuracy. Every part of a high-quality timepiece, from delicate gear trains to balance wheels, requires careful attention and skill. The precision and control offered by this tool enable watchmakers to achieve the highest standards of craftsmanship, ensuring that each timepiece functions reliably and beautifully.

This article explores the history, functionality, and enduring importance of this vital instrument. It provides a detailed guide for enthusiasts, collectors, and professionals alike, highlighting how mastery of such tools preserves the tradition, artistry, and technical excellence of watchmaking. By understanding its applications and significance, readers can appreciate both the art and science behind creating precise, lasting timepieces.

History of the Watchmaker Lathe

The origins of the watchmaker lathe trace back to the 19th century, a time of remarkable progress in precision tooling. Early watchmakers relied on simple hand tools, which made crafting complex timepieces a slow and painstaking process. As the popularity and complexity of watches increased, there was a growing need for specialized machinery that could meet higher standards of accuracy and efficiency. The industrial revolution introduced advanced measuring tools, such as the Millionomètre, which allowed measurements down to a millionth of a meter and significantly elevated the precision of horological craftsmanship.

Swiss watchmakers, particularly those in the renowned “Watch Valley” region, played a crucial role in refining lathe designs to meet the exacting demands of professional watchmaking. Their innovations ensured that components could be produced with minimal error, improving both the reliability and durability of timepieces. These improvements laid the foundation for modern lathe technology, emphasizing the importance of precision in every aspect of watch construction.

Over time, these developments culminated in the creation of compact, highly accurate watchmakers lathes that remain indispensable in both professional workshops and hobbyist settings today. Celebrated for their balance of traditional craftsmanship and technological sophistication, these lathes allow watchmakers to produce work that is not only technically precise but also artistically refined. Their enduring presence highlights the skill, experience, and dedication that define the craft of watchmaking.

Introduction to the Watchmaker Specialized Lathe

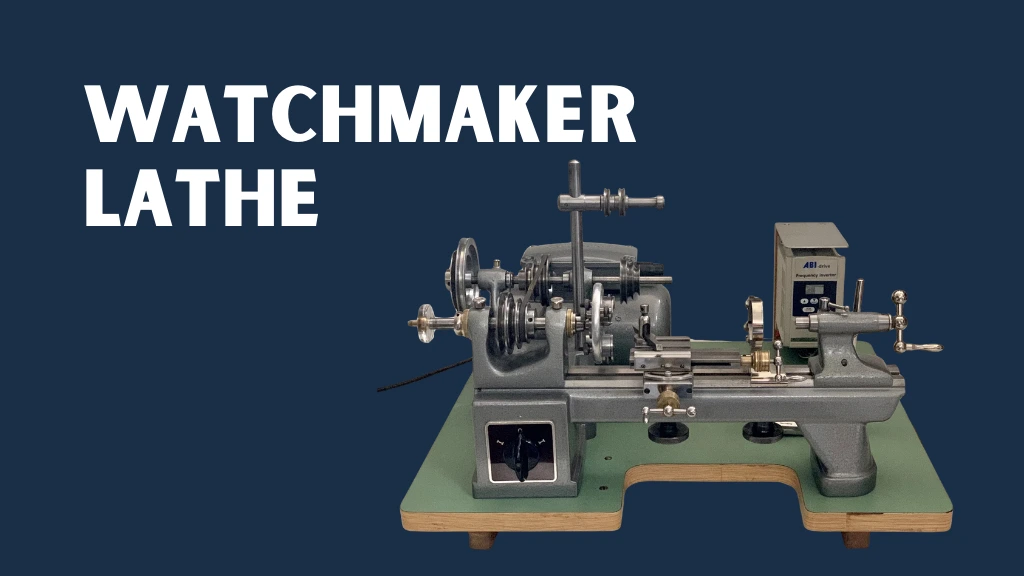

A watchmaker lathe is a specialized miniature lathe designed for delicate, highly precise tasks. It is specifically engineered to handle the tiny components of a mechanical watch, such as gears, arbors, and balance staffs. The lathe typically operates on spindles ranging from six to ten millimeters in diameter, allowing for exceptional control when working with minuscule parts.

The lathe is composed of several key components that ensure accuracy and stability. The bed provides a solid foundation, often built in WW (Webster/Whitcomb) or D-style bar configurations, to minimize vibration. The headstock houses the spindle and motor, which rotate the workpiece, while the tailstock supports the opposite end to maintain alignment during cutting operations. The tool rest allows the watchmaker to position and guide cutting tools with precision, and collets or chucks hold components securely, enabling work with extremely fine tolerances.

Each element of this lathe is carefully designed to facilitate intricate work. From stable foundations to precise spindle control, every part contributes to the overall performance, allowing artisans to achieve the highest standards of accuracy in watchmaking. The design reflects the combination of engineering skill and craftsmanship required for producing delicate timepiece components.

Applications in Watchmaking

The versatility of the watchmaker lathe extends across many essential tasks in horology. It is primarily employed for component fabrication, allowing artisans to create parts such as arbors, gears, and balance staffs with extreme precision. These components are critical for ensuring that a timepiece operates accurately and reliably, making this tool an indispensable element of the watchmaking process.

Beyond fabrication, the lathe plays a vital role in repairs and restoration. Antique watches often include parts that are no longer manufactured, requiring watchmakers to either repair the originals or reproduce them with meticulous attention to detail. Using the lathe, they can restore these timepieces to their original functionality while preserving their historical and aesthetic value, maintaining both accuracy and authenticity.

The lathe also serves an important function in customization. Watchmakers can modify existing components to meet specific aesthetic or functional requirements, such as creating specialized gears or bushings to enhance performance or adapt a watch for a unique design. This highlights the lathe’s ability to support both technical precision and creative craftsmanship, making it a versatile and essential tool in any horology workshop.

Essential Attachments and Accessories

To maximize functionality, watchmakers lathe often come with a variety of specialized attachments. Gravers, for example, are hand tools used to cut and shape materials with exceptional precision. Crown chucks provide secure handling of crowns during modifications, while balance chucks hold balance wheels steady during servicing. Draw-in spindles assist in inserting workpieces into collets, enhancing control during delicate operations. These attachments collectively expand the lathe’s capabilities, making it possible to handle a wide range of tasks with accuracy.

Using these attachments effectively requires both skill and experience. Even small mistakes can compromise the precision of the finished component, which is why careful handling is essential. Many watchmakers spend significant time practicing with each tool to ensure consistent results. This level of dedication demonstrates that mastery is not solely about owning a lathe but also about understanding how to use it properly.

Professional watchmakers emphasize the importance of hands-on training and mentorship to achieve expertise. Learning from experienced artisans provides insights that cannot be gained from manuals or videos alone. By combining proper technique, practice, and guidance, watchmakers can fully leverage the lathe and its attachments, producing components that meet the highest standards of precision and craftsmanship.

Leading Manufacturers and Models

Selecting the right watchmaker machine depends on several important factors. The first consideration is the intended use. Will the lathe be primarily for repairs, restorations, or fabricating new components? Professional watchmakers who work with antique or custom watches often prioritize precision and durability over cost, while hobbyists may place greater emphasis on versatility and ease of use to handle a variety of projects.

Budget is another key factor when choosing a lathe. High-quality machines can require a significant investment, but their long-term value often justifies the expense. A reliable lathe can save time, reduce errors, and ensure consistent performance over many years, making it a critical decision for anyone serious about watchmaking.

Brand reputation and support are also crucial considerations. Choosing manufacturers with a proven history of producing precise and dependable tools reduces the risk of defects or mechanical problems. The availability of replacement parts, clear guidance, and active user communities, including online forums and professional networks, further helps watchmakers maintain their equipment and select the model that best suits their specific needs.

Choosing the Right Watchmaker’s Lathe

Selecting the right watchmaker specialized lathe depends on several important factors. The intended use is the first consideration. Will the lathe be used for repairs, restorations, or fabricating new components? Professional watchmakers who handle antique or custom watches often prioritize precision and durability over cost, while hobbyists may focus more on versatility and ease of use to accommodate a variety of projects.

Budget is another key factor when choosing a lathe. High-quality machines can require a significant investment, but their long-term value often justifies the initial expense. Investing in a reliable lathe can save time, prevent errors, and ensure consistent performance over many years, making it a critical decision for anyone serious about watchmaking.

Brand reputation and support also play a major role. Selecting manufacturers with a proven history of producing precise and reliable tools reduces the risk of defects or mechanical issues. Availability of replacement parts, clear guidance, and active user communities, such as online forums and professional networks, further assist watchmakers in maintaining their equipment and choosing the model best suited for their specific needs.

Conclusion

The watchmaker lathe remains a vital tool in horology, combining precision, tradition, and modern engineering. Its evolution has enabled artisans to fabricate, repair, and customize components with unparalleled accuracy. Both professional watchmakers and hobbyists rely on such specialized tools to achieve results that standard machines cannot replicate. This enduring instrument reflects the skill, experience, and dedication of the watchmaking community.

Beyond its technical uses, this type of lathe bridges artistry and science in watchmaking. Mastery requires hands-on experience, careful technique, and deep knowledge, demonstrating true expertise. Its reliability has been trusted by generations of watchmakers, highlighting its authoritative role in the craft. By using it skillfully, watchmakers preserve the precision and legacy of horology for years to come.

Frequently Asked Questions

How does a specialized lathe for fine work differ from a regular lathe?

While both machines perform turning operations, a watchmaker’s lathe is designed for the delicate work of horology. It handles smaller components with greater precision, making it ideal for crafting and repairing timepieces, whereas general-purpose lathes focus on larger, less intricate work.

Are there applications for these specialized lathes outside of horology?

Yes, watchmaker turning machines are versatile and often used in jewelry making, model engineering, and other fields requiring fine precision. Their ability to work with small, intricate components makes them valuable in various crafts and industries.

Are there contemporary machines that can replace classic precision lathes?

Modern mini lathes exist and offer digital controls or automated features. However, many professionals continue to prefer traditional lathes for their superior precision and tactile control, which is essential for delicate operations.

How should I maintain a watchmaker machine?

Proper maintenance includes regular cleaning, lubrication, and careful storage to prevent damage or corrosion. Routine inspections and calibration ensure consistent accuracy and prolong the lathe’s lifespan. Many expert watchmakers follow strict maintenance schedules to uphold the quality of their work.

What factors affect the longevity of a watchmaker machine?

Material quality, frequency of use, and adherence to maintenance guidelines all play roles in a lathe’s longevity. Choosing a reputable manufacturer and using the lathe under recommended conditions ensures it remains a reliable tool for many years.