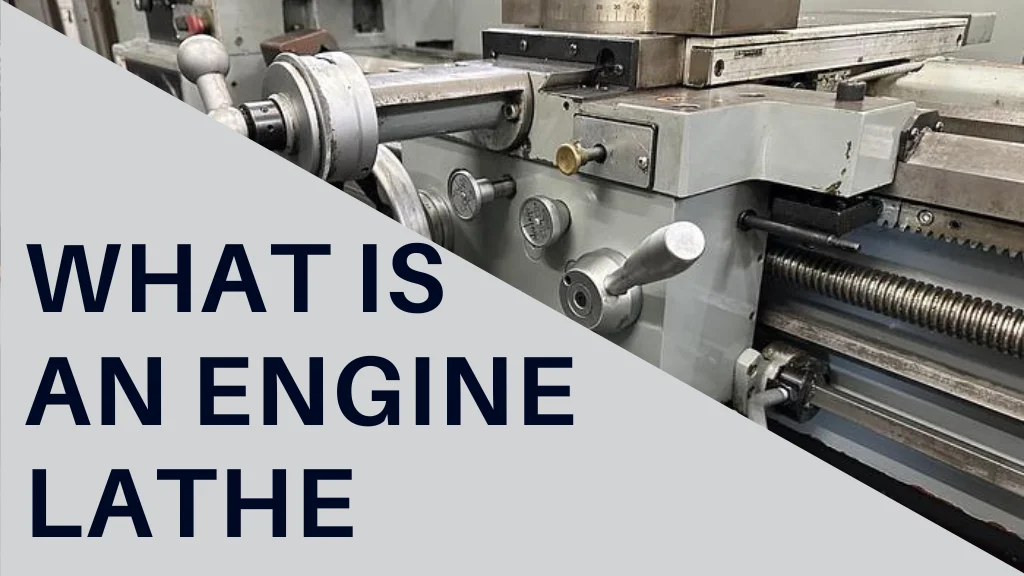

Still, you may have come across the term “ What is an Engine Lathe ” and wondered what it means if you’re new to the world of turning. Well, the moment I’m then to clear up any confusion. Machine lathe is just another word for “ lathe ”.

The term “ Engine lathe ” dates back to the Industrial Revolution, when mechanical lathes weren’t the norm. The machine lathe is substantially used to produce colourful, structured essence. The machine uses advanced slice tools to give it the masked shape.

Work Which You Can Do With An Engine Lathe

Boring

Boring is the procedure of adding an opening in the asked essence. With a machine lathe, you can fluently do this step in no time. It can help you produce gun barrels and machine cylinders.

Drilling

We all know what drilling is. The machine lathe successfully helps us drill different corridors of the ministries. This engine makes the entire drilling procedure a lot more effortless.

Turning

A machine lathe is used to complete the turning process. In this process, the essence rotates, and the unwanted corridor gets cut. The whole turning process is unbelievable without a machine lathe these days.

Facing

In looking, we can see the essence being smoothened to give it a more finished look. With a machine lathe, you can do this with ease.

Capacities of an Engine Lathe

These are among the major operations typically carried out in a metal workshop, and a machine lathe is essential for performing them efficiently. It is widely used across various sectors, handling tasks like knurling, threading, cutting, and shaping. The versatility of a machine lathe allows it to be used beyond just workshops, including manufacturing and industrial settings. However, it is primarily utilized in the machining industry to create precise parts and shapes for mechanical applications. Its ability to perform multiple functions makes it a core tool in metalworking.

Corridor of An Engine Lathe

A lathe consists of four main parts that are essential for its operation. These include the gears, which help control speed and torque; the carriage, which holds and moves the cutting tool; the tailstock, which provides support to the workpiece; and the driving pulley, which transfers power to rotate the spindle. Each of these components plays a critical role in ensuring the machine functions accurately and efficiently.

Gears

The main intention of the tackle in a lathe, which refers to the gear system or drive mechanism, is to transmit power directly to the spindle. This transferred power is essential for rotating the workpiece and plays a key role in supporting the cutting process. By delivering consistent motion and force, the tackle ensures smooth operation and precise results during machining. Without this mechanism, the lathe wouldn’t function effectively.

Carriage

The carriage is built up on the internal side of the engine. It helps to dampen the shivering of the lathe. A carriage supports, attendants, and also feeds the tool. The carriage itself has five corridors as well.

- Saddle

- Cross-slide

- Compound rest

- Tool post

- Apron

In this corridor, the cross-slide helps the tool feed. It provides a slitting act to the device, and it can be handled by hand as easily.

Tailstock

The tailstock primarily provides support and stability during the machining process. It consists of several important components that contribute to its functionality. Typically, the tailstock is mounted on the lathe bed and can be adjusted as needed to accommodate different workpiece lengths. Its role is crucial when performing operations like drilling or supporting long materials to ensure precision and reduce vibration.

Stepped Pulley

The stepped pulley is an important part of the engine, as it helps control spindle speed effectively. You must manage the spindle speed carefully to perform the task with the right level of precision. Proper speed adjustments allow the machine to operate smoothly and improve overall performance. Without accurate control, the quality of the machining process can be compromised.

Another corridor of An Engine Lathe

Piecemeal from these corridors, there are some major controls of an Engine lathe. There’s an authority whip to swing the engine on or out. Also, we can find a handwheel that helps handle the tailstock. There’s similarly a crossfeed clump and some speed control clods to operate as well. Picking up the capacities and uses of these controls is veritably important for operating a machine lathe.

Precautions Using the Engine Lathe

- While the engine lathe is indeed a very useful tool, it needs to be handled precisely. We need to take preventive measures for our own sake. A machine lathe comes with a moving chuck and race, there are cutting tools and edges as well. So, mishandling the device can be a bit dangerous for your health.

- Also, some fractions of the stock may come out of the engine and hit you. The essence chips can be sharp and burning as well.

- To keep yourself safe while using the tool, you need to operate the machine precisely and handle it with proper care. You should always wear safety spectacles to keep your eyes out of danger’s way. Make sure to switch the machine off previous to making any adaptations.

- Across the board, the risk is still broadly manageable. You just need to negotiate it with the correct precautions. But, in return, you get an entire machine to help you cut and shape your essence professionally.

Conclusion

A machine lathe is a vital engine device in the area of metalworking and manufacturing. Its vertical exposure, protean functionality, and crucial factors were similar to the bed, headstock, tailstock, carriage, and lead screw manufacture necessary for colourful operations. The machine lathe’s capability to swing workpieces and relate slice tools with perfection facilitates the creation of intricate corridors, from shafts to bushings, contributing significantly to the product of ministry and custom factors.

FAQs

What’s the main goal of an engine lathe?

An engine lathe swings the workpiece horizontally, allowing a cutting tool to shape and remove material. It was originally used in metalworking.

How does a machine lathe differ from other lathes?

Machine lathes feature a vertical setup, which distinguishes them from perpendicular lathes, and they offer versatility in handling various materials and cutting tasks.

What are the crucial factors of a machine lathe?

So Factors contain the sack, headstock, tailstock, carriage, and lead screw, each disporting a pivotal part of the machine’s function and perfection.

What are some familiar operations of machine lathes?

Operators extensively use machine lathes in metalworking, woodworking, and manufacturing to perform tasks like turning, facing, threading, and creating precision parts with symmetrical accuracy.