In the world of precision machining, the choice between dead centers and live centers for a lathe machine is a critical decision that can significantly impact the quality and efficiency of machining operations. These two types of centers serve as essential components in lathe setups, providing crucial support to the workpiece as it undergoes cutting, turning, and shaping processes.

So, in this guide, we are going to understand dead and live centers, the purposes and functions of these both, and much more.

What Are Lathe Dead Centers?

A lathe dead center is a fixed point within the tailstock of a lathe machine, designed without any angular tilt. This essential component is commonly employed in woodturning applications. When installed in the tailstock, the dead center facilitates slow rotation. For enhanced performance, certain applications may necessitate the application of lubricants.

Beginners Guide To Dead Centers

Dead centers are solid, unyielding points fixed at a specific angle. Soft dead centers also provide a movable tip for added flexibility.

Dead centers offer versatility beyond that of live centers. While live centers are more commonly used, dead centers can effectively handle larger and heavier machines.

Using a dead center can generate friction on the tailstock due to continuous contact with the workpiece, potentially resulting in heat build-up. It’s important to note that having a dead center on the headstock does not pose a similar issue.

Like live centers, dead centers feature a Morse taper, allowing them to be employed in various operations despite being stationary.

What Is the Purpose of a Dead Center?

A dead center, which doesn’t rotate freely, is a stable support for the workpiece, anchoring it at one end of the machine. When employed in a fixed position, the dead center generates friction between the workpiece and the live center due to the workpiece’s rotation. A dead center’s primary function is to secure a workpiece within a lathe machine, typically between the headstock and tailstock.

Variations of the Dead Center

Various types of dead centers are available on the market, but two notable variations stand out:

Drive Centers:

The drive center is ideal if you prefer a dead center that resembles the traditional design. It reaches a typical dead center but features a flattened tip. While it doesn’t rotate, it exerts significant pressure to hold the metal lathe securely. This type is commonly used for demanding hardwood-cutting tasks due to its sturdy bearing.

Half-Dead Center (Grip Center):

The half-dead center, also known as the grip center, is the most popular variant. It excels in softwood cutting because of its internal bearing grip.

What Are Lathe Live Centers?

Live centers have gained greater popularity compared to dead centers. These workpieces incorporate movable components that enable them to rotate freely. In woodturning on a wood lathe, employing live centers on both the headstock and tailstock is ideal. Advancements in technology have replaced dead centers with live centers, establishing them as the standard in lathe operations.

The primary reason behind this transition is that dead centers introduce friction, which can result in wood burning. In contrast, live centers feature a conical point that moves freely, eliminating the risk of such burning.

Beginners Guide To Live Centers:

- Morse Taper Shaft: Live centers feature a tapered shaft known as a Morse taper, which can be inserted into either the headstock or tailstock. This shaft includes a ball feature that enables free movement.

- Ideal for Spindle Work: Live centers provide additional support for spindle work. The shaft of the live center can securely clamp down on hardwood, eliminating concerns about friction during contact with the workpiece.

- Versatile Point Options: Live centers offer various interchangeable points. Unlike solid metal lathes, these tools have a hollow area where you can insert a knock-out till for machining. This design allows for easy removal and replacement of points as needed.

Function of the Live Center

Like a dead center, a live center secures and supports the workpiece during machining operations within a lathe’s headstock or tailstock.

Live centers come in various forms, including:

Spring-Loaded Centers: These centers incorporate an internal spring mechanism to maintain consistent tension on the lathe’s point.

Pipe Centers (Bullnose Centers): Pipe centers feature a conical shape with a wider diameter instead of a sharp tip. The conical contact surface rotates in alignment with the pole lathe’s included angle, ensuring uniformity.

Cup Centers: Cup centers resemble standard centers but include a surrounding ring around the point. The ring’s design and included angle provide enhanced support for woodturning operations.”

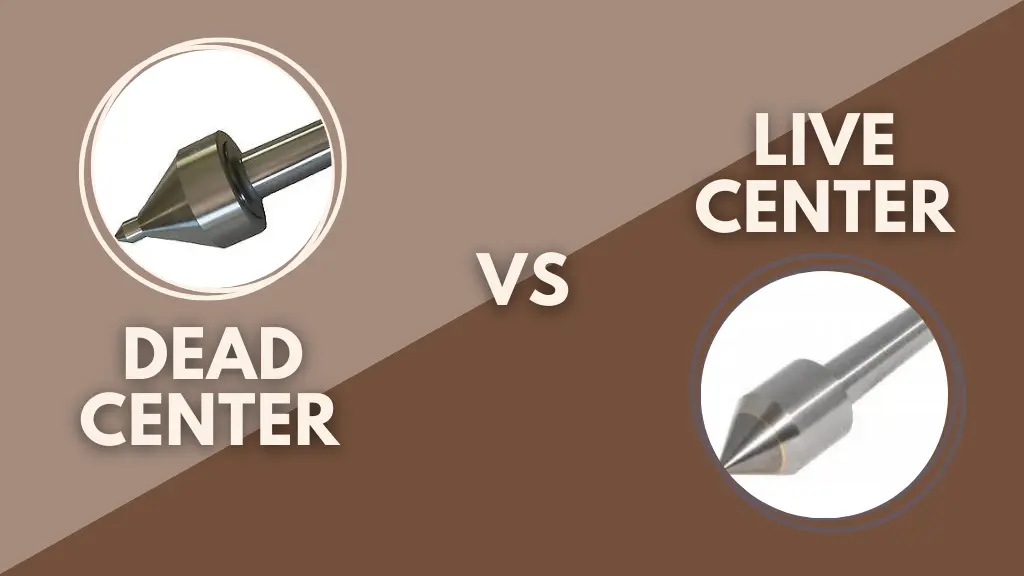

Dead Centers vs Live Centers

Dead centers and live centers are tools used in machining and metalworking, particularly in lathe operations. They are both types of centers that support and rotate the workpiece during machining processes, but they differ in their design and functionality.

Live Centers:

- Friction Reduction: Live centers have a built-in mechanism that reduces friction between the workpiece and the center, preventing overheating and burn marks.

- Diverse Applications: Live centers are highly adaptable and suitable for various materials and machining operations, making them versatile.

- Movement: Live centers rotate freely, while dead centers remain stationary.

- Internal Bearings: Live centers have bearings for rotation, whereas dead centers lack this feature.

Dead Centers:

- Simplicity: Dead centers are straightforward and have fewer moving parts, making them simpler to set up and use.

- Stability: Due to their stationary nature, dead centers provide stable support, which can be advantageous for certain precision tasks.

- Friction: Dead centers can generate friction and heat, while live centers reduce the risk of overheating and burning.

- Applications: Dead centers are suited for stationary work, while live centers are ideal for spinning operations.

Conclusion

Live and dead centers represent the two primary types of lathe centers available. While they share similar functions, they differ in terms of their internal bearings.

In summary, dead centers are the choice if you require a stationary center for your lathe tool. Conversely, if you seek a center that rotates freely, live centers are the preferred option.

FAQs

-

What is the primary purpose of a center in machining?

- The primary purpose of a center is to support and locate the workpiece during machining operations, ensuring accuracy and precision in metalworking processes such as turning, grinding, and milling.

-

What is the key difference between dead centers and live centers?

- The main difference is that dead centers do not rotate with the workpiece, remaining stationary, while live centers rotate with the workpiece, providing continuous support.

-

When should I use a dead center?

- Dead centers are suitable for applications where continuous rotation is not required. They are often used for heavier workpieces and in operations where the workpiece does not need to rotate continuously.