Discover why lathes are so expensive—these powerful machines, often called the “Mother of All Machine Devices,” can handle a wide range of complex projects. Their high cost comes from the precision engineering, durable materials, and versatility they offer. Lathes are essential in both industrial production and detailed craftsmanship, making them a long-term investment.

Understanding a Lathe

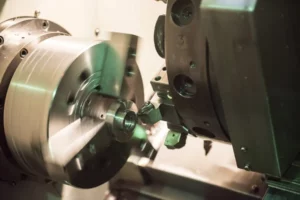

A lathe is a powerful machine that shapes wooden or metallic workpieces into various forms. It rotates the workpiece around an axis while a cutting tool actively removes unwanted material to create the desired shape. Users operate either a metal lathe or a wood lathe, depending on the project needs. Manufacturers rely on lathes to produce symmetrical and accurate components. These machines are crucial in industries like automotive, furniture making, and aerospace, where precision and efficiency are key.

Lathe machine tools perform various operations such as shaping, sanding, designing, drilling, cutting, and turning both wood and metal. Industries actively use them in metalworking, woodworking, spraying, glass processing, and other wood-turning devices. These machines help create precise, symmetrical parts with efficiency and consistency.

Why are Lathes so expensive?

Lathes are expensive due to their heavy-duty machinery, robust metal bodies, and powerful motors. All the components—such as precision gears, bearings, and control systems—are costly to manufacture. These machines are built to shape various materials with accuracy and durability, making them a high-value investment for professionals.

A large number of employees are involved in machining, designing, calibrating, and assembling lathe parts, which significantly adds to the overall cost. Additionally, the final assembly requires precision and skilled labour. The shipping method also plays a major role, as transporting these heavy and bulky machines safely increases expenses. All these factors contribute to the high cost of lathes.

So let’s search out why these lathes are so expensive because of looking at how they efficiently work and some of the components that are used, especially in metalworking and woodturning.

Demand And The Materials

- Metalworkers and Woodturners also need expert training and schooling to be able to turn the wood shape into a wooden showpiece, furniture or different sound instruments, which need to be accurate to fulfil their characteristics. You can not imagine a wooden showpiece and musical instrument that is not perfectly made and makes different sounds.

- Woodturning is a specific art in which users ask for expert training, quality motors, the best machinery, and special safety regulations. Secure lathes, with all the rules and precautions in the workplace, that’s why they will be more expensive lathes.

Resting Your Tools

- Use various devices, screws, and tools to shape and design wood during turning.

- Woodturners press different bits against the spinning wood to create desired textures.

- Always position tools correctly for safety and accuracy.

- The tool rest holds tools steady during operation and must be locked in place.

- A loose tool rest is dangerous and can cause serious injury.

The Costs And The Brands

- Wood Lathes and Metal lathes are available in different sizes with different functionalities, which affect the price of lathes. Your low lathes will cost you about $250 – $450. All lathes are small in size and don’t come with all the bobs, bits, and pieces that you can expect with mid-size or high-size lathes.

- Mid-size lathes look bigger, with more bells and whistles, and the price is anything from $450 to $850 in range. These lathes are the best if you are more serious about working with woodturning and are looking for a larger number of possibilities.

- Expert woodturners and specialized factories purchase large-sized lathes for thousands of dollars. These lathes can be larger, or massive, and some of them other specially digitised for the greatest accuracy and other detail.

The most expensive parts of a lathe

I did a lot of research to search out what the most expensive parts of the wood lathe and metal lathes and here is what I collected data about this.

-

Cast Iron

Cast iron forms the majority of the components in most lathe tools. This material is largely responsible for the machine’s overall weight, size, and cost. Cast iron is chosen for its durability and vibration-dampening qualities, making it ideal for precision work. Its solid construction ensures stability during high-speed operations. Most industrial lathes rely on cast iron for long-term strength and reliability.

-

The motor

Manufacturers design the motor to run at various speeds without sacrificing torque angle. This performance demands more engineering effort than typical motors found in standard speed tools for lathe machines. The motor must maintain consistent power across speed ranges to support precise machining tasks. Engineers often integrate enhanced durability and advanced control systems to handle variable loads. As a result, these motors offer improved efficiency and reliability for demanding lathe operations.

-

Machining of the spindle

Engineers carefully design and manufacture the headstock and tailstock parts of lathes to operate with extremely high accuracy and long-term durability. This precision engineering ensures the machine runs smoothly and consistently over many years. However, the complexity and meticulous work involved in producing these components significantly increase the overall cost of lathe machining.

Conclusion

Lathes are expensive machine devices, and metalworking, woodturning a very different arts. It is not tough to see why lathes are so expensive. For a proper working lathe, the best size, made from good quality materials to ensure accuracy and security, which you might have to spend more cash on. Woodturning and metalworking can be very rewarding if done right, but there is a very catchy. These lathes are best for serious woodturning. They offer more features and greater possibilities.

FAQs

What tasks do lathes perform?

People have used lathes to shape various materials since ancient times. Since ancient Egypt, craftsmen have used lathes to shape materials into finished products.

Should I get a cheap lathe and upgrade later?

The answer is no. However, I recommend getting proper training first. Try using someone else’s lathe in a beginner class or visit a professional shop for a few hours of experience. This approach will give you a better understanding and help you make an informed decision about which lathe to buy.